King Tut's PTUNING Turbo Kit Build

#21

Community Organizer

Join Date: Nov 2006

Location: America !!! fuk yeah.

Posts: 5,135

Likes: 0

Received 9 Likes

on

9 Posts

The oil lines are fine. You really should consider changing the coolant lines to stainless. Those lines don't hold up. I went through 4 of them before converting. Now zero issues. When they leak you have to disassemble everything. Just trying to save you frustration later.

#22

Community Organizer

Join Date: Nov 2006

Location: America !!! fuk yeah.

Posts: 5,135

Likes: 0

Received 9 Likes

on

9 Posts

One more thing. You might want to upgrade the fan fuse holder to a better one. They include a 30 amp holder but that fan draws more and mine exploded. It's appended to others as well.

#23

Registered User

Thread Starter

Join Date: Jul 2014

Location: Fort Walton Beach, FL

Posts: 2,629

Likes: 0

Received 53 Likes

on

42 Posts

The oil lines are fine. You really should consider changing the coolant lines to stainless. Those lines don't hold up. I went through 4 of them before converting. Now zero issues. When they leak you have to disassemble everything. Just trying to save you frustration later.

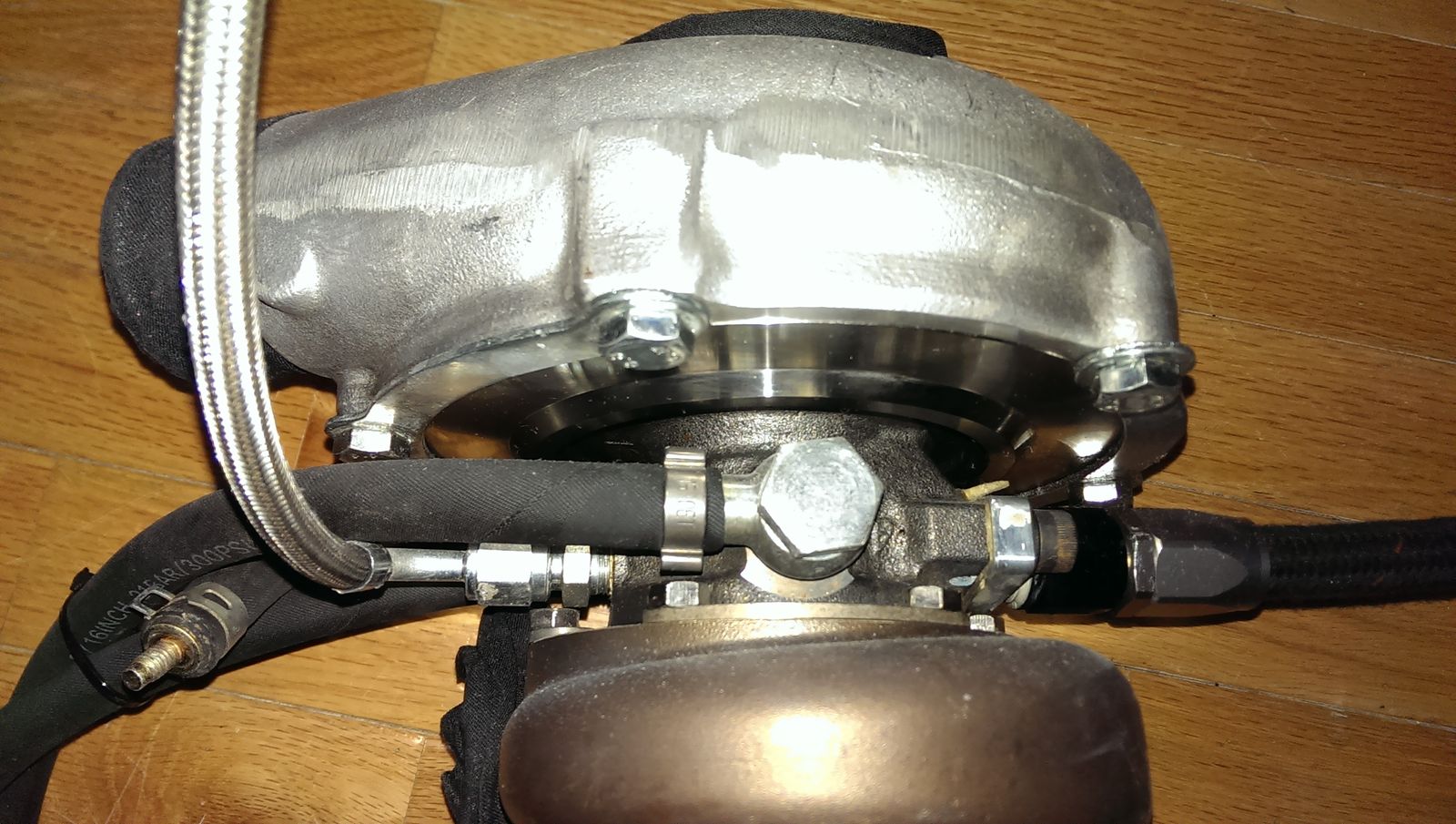

I don't have that style. I have tried to show you in the photos, but mine look just like the line in right side of this photo:

PTUNING says the line is SS braided Teflon with black PVC coating. There is no upgrading those lines. Then I slid the heat protection over them.

#25

https://www.s2ki.com/s2000/topic/986...s-backing-out/

To this day I still have this problem even with the locking tabs. I recommend to check every six months by take out the turbo and re-tighten the inconel nuts.

To this day I still have this problem even with the locking tabs. I recommend to check every six months by take out the turbo and re-tighten the inconel nuts.

#26

Registered User

Thread Starter

Join Date: Jul 2014

Location: Fort Walton Beach, FL

Posts: 2,629

Likes: 0

Received 53 Likes

on

42 Posts

I didn't get much time to work on the car on Day 3 after work, but I did finally come to a realization that the turbo was never going to mount properly with the way I had the coolant lines run. The turbo needed to be rotated more towards the motor mount, and that area was occupied by the coolant line. I had noticed this multiple times before and even pulled the turbo out of the car to readjust the angle of the inner coolant line once before. I finally yesterday pulled the turbo back out a second time and reversed both coolant lines so they go up instead of down, and for the first time I was able to rotate the turbo into the correct position and had everything connected with no binding. I will finish tightening down everything after work today and get some photos. Should be downhill from here.

#27

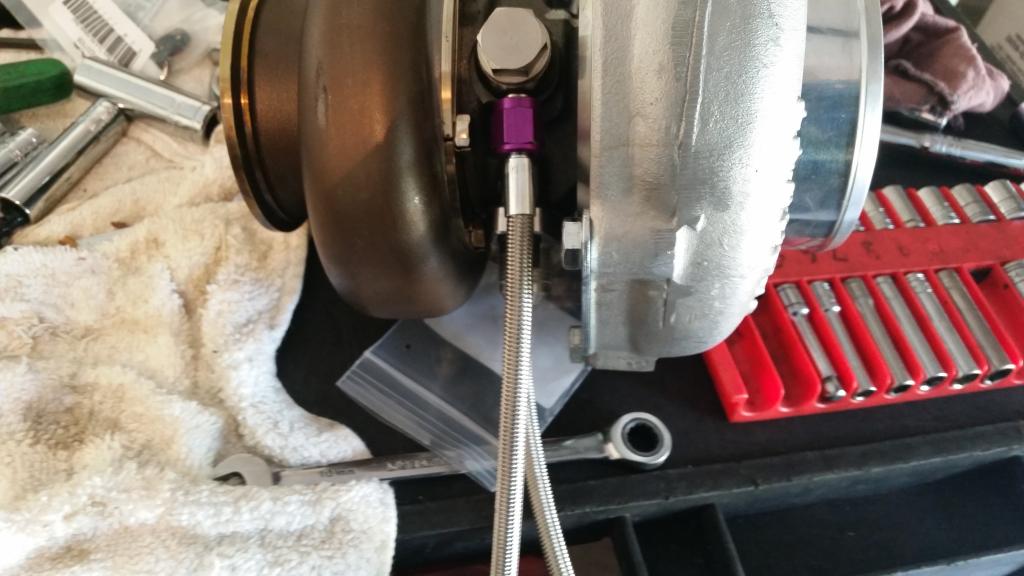

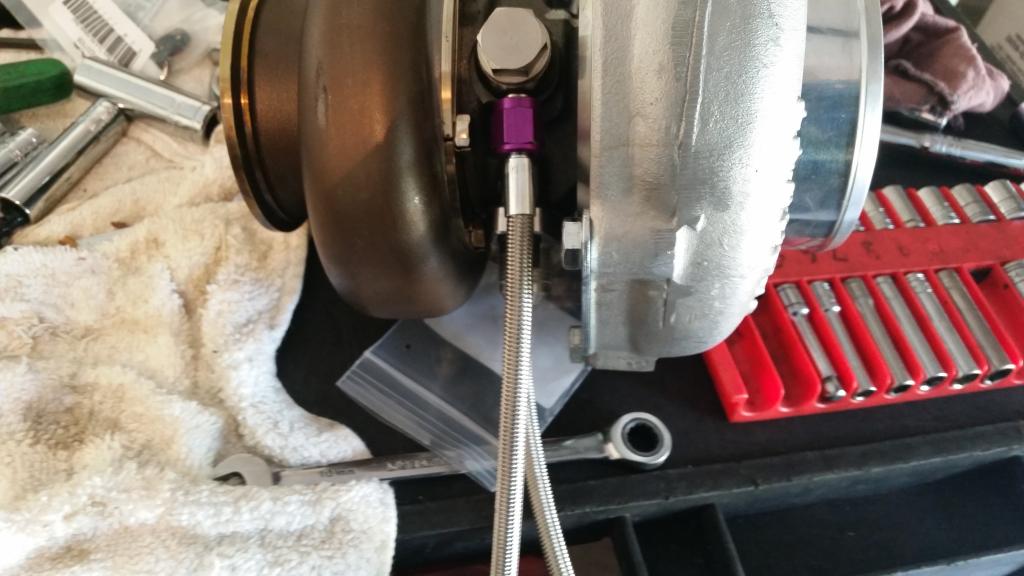

The rubber lines for coolant are the ones Jim is referring to. They leaked on his car 4 times. Here is what Jim, myself and others have used to replace them. Only thing I wish I had done different, was got ones that weren't purple. I have nothing else purple in my bay lol.

You're making good progress man. Excited to see your results. Mounting the turbo is for sure the hardest part. It will definitely be downhill from there on.

You're making good progress man. Excited to see your results. Mounting the turbo is for sure the hardest part. It will definitely be downhill from there on.

#28

Just a quick note about the water cooling, although it looks like you have the center section clocked correctly.. Garrett says about 20 degrees is ideal, with inlet port on the low side and exit on the higher end.

https://www.turbobygarrett.com/turbo...er_Cooling.pdf

https://www.turbobygarrett.com/turbo...er_Cooling.pdf

#29

Registered User

Thread Starter

Join Date: Jul 2014

Location: Fort Walton Beach, FL

Posts: 2,629

Likes: 0

Received 53 Likes

on

42 Posts

The rubber lines for coolant are the ones Jim is referring to. They leaked on his car 4 times. Here is what Jim, myself and others have used to replace them. Only thing I wish I had done different, was got ones that weren't purple. I have nothing else purple in my bay lol.

You're making good progress man. Excited to see your results. Mounting the turbo is for sure the hardest part. It will definitely be downhill from there on.

You're making good progress man. Excited to see your results. Mounting the turbo is for sure the hardest part. It will definitely be downhill from there on.

#30

Registered User

Thread Starter

Join Date: Jul 2014

Location: Fort Walton Beach, FL

Posts: 2,629

Likes: 0

Received 53 Likes

on

42 Posts

Just a quick note about the water cooling, although it looks like you have the center section clocked correctly.. Garrett says about 20 degrees is ideal, with inlet port on the low side and exit on the higher end.

https://www.turbobygarrett.com/turbo...er_Cooling.pdf

https://www.turbobygarrett.com/turbo...er_Cooling.pdf