Resurrecting/restoring a track day legend

#81

UK Moderator

Thanks DD for confirming suspicions re the little end.

I know it was a little before my time but similar issues used to occur on some WW2 aircraft engines. Pilots tended to close the throttles during high speed dives which meant that for too many cycles there was insufficient gas pressure force to counter the tensile inertia forces on the rods from the pistons. From this experience we can therefore conclude that Si may have spent simply too much time 'backing off' during those hundreds of circuit days. His new car just has to be driven harder then to avoid a repeat of this failure mode.

I know it was a little before my time but similar issues used to occur on some WW2 aircraft engines. Pilots tended to close the throttles during high speed dives which meant that for too many cycles there was insufficient gas pressure force to counter the tensile inertia forces on the rods from the pistons. From this experience we can therefore conclude that Si may have spent simply too much time 'backing off' during those hundreds of circuit days. His new car just has to be driven harder then to avoid a repeat of this failure mode.

#83

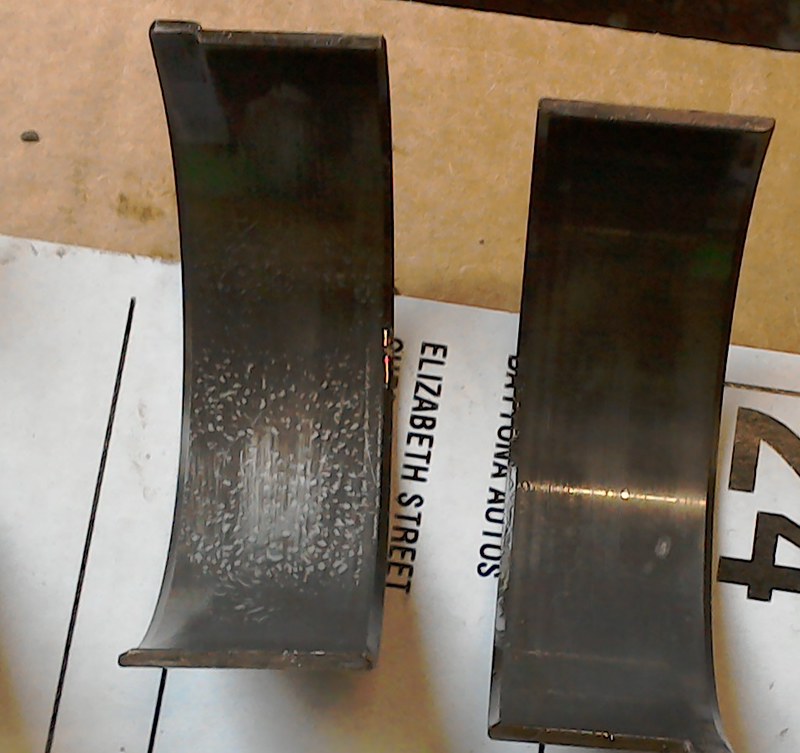

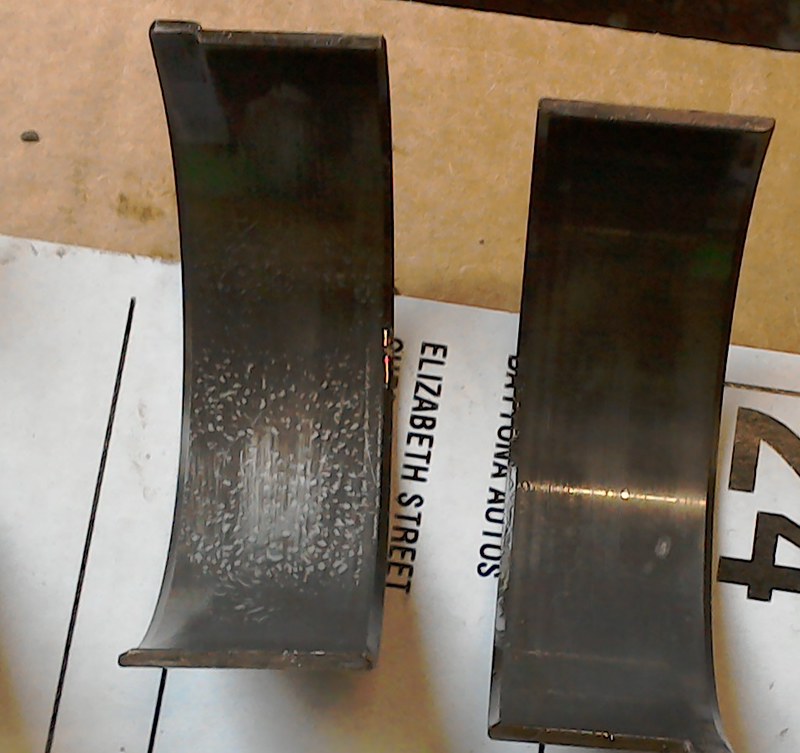

Just got all the bearings and gaskets delivered for the states after over a month of faffing about in the end i saved over £400 but that was with a set of big end shells and rod bolts for my current S, was it worth it, well to me no as the wait and worry about paying for the parts then them going missing and then short order so parts were held then no communication and having to ring the states to track down where the parts were, and in the end i still had to be rescued by Si as 1 half bearing was missing and they thought sending me two accord bearings would work???,

So the first job was to replace the big end bearings in my car as every now and then if she had being standing for a couple of days there was a bearing rap for a split second on start up and it had being bugging me for a while and an oil sample i had checked showed a high copper content so as i was ordering the parts for the engine rebuild it seemed rude not to throw a set in mine as well, maybe they didn't need replacing and the old saying if it an'it broke may come back to bite me only time will tell

,

,

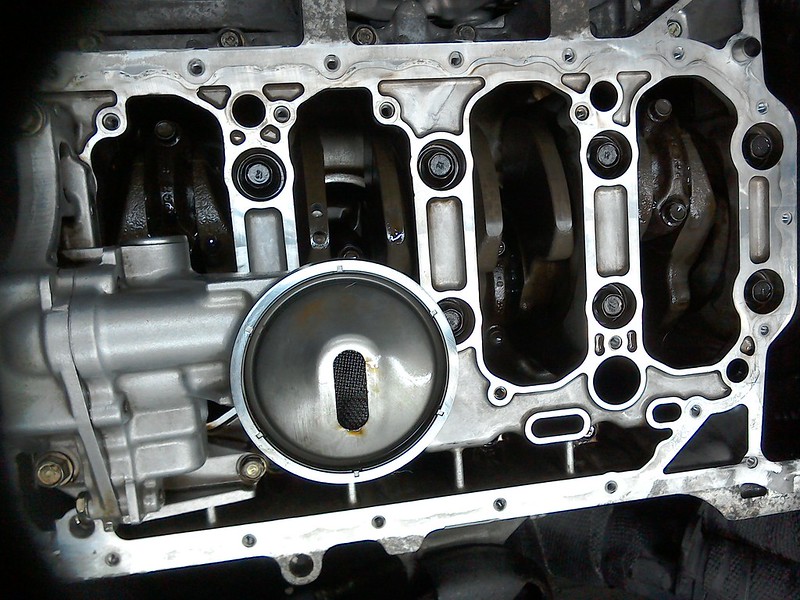

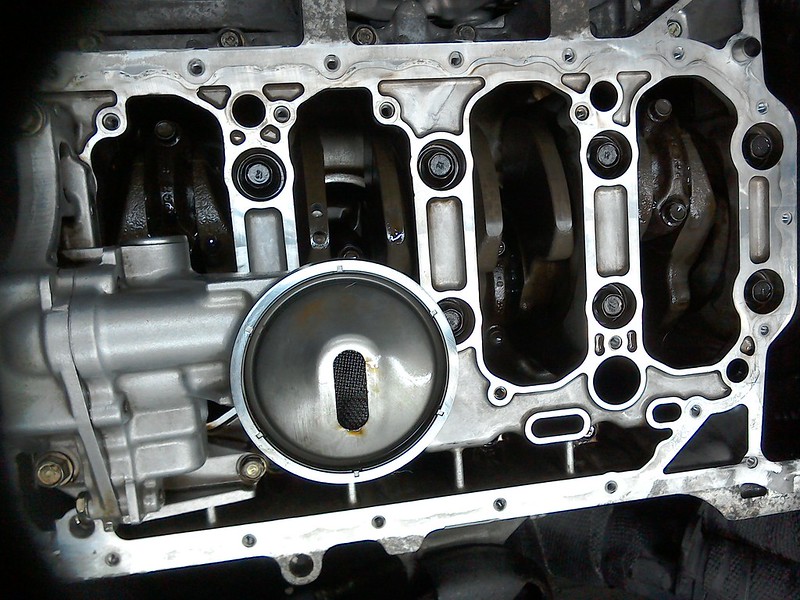

next job for the engine rebuild is to send the crank and components off for balancing then i can start reassembling it if i can remember where it all goes

So the first job was to replace the big end bearings in my car as every now and then if she had being standing for a couple of days there was a bearing rap for a split second on start up and it had being bugging me for a while and an oil sample i had checked showed a high copper content so as i was ordering the parts for the engine rebuild it seemed rude not to throw a set in mine as well, maybe they didn't need replacing and the old saying if it an'it broke may come back to bite me only time will tell

,

,next job for the engine rebuild is to send the crank and components off for balancing then i can start reassembling it if i can remember where it all goes

Last edited by Daytona-Dave; 12-11-2016 at 10:41 PM.

#84

One of the first jobs to address was to make sure the front subframe bolts would come out as we would be dropping the engine out complete with the frame as this is the best way to remove the engine and box as a unit, the problem is that the front frame bolts often seize in and after a trip around the forum have seen case's where these bolts have snapped causing a right headache so the first job was to soak them for a few days just in case i encountered this problem, this is done by spraying plus gas through the holes in the chassis leg just behind the X member and above the rack and the same on the n/s as well giving it a good dosing a couple of times a day,

The other job was to clean all the rust of any exposed threads that needed to be undone and spray them with penetrating oil, the reason being to stop any of the rust being dragged into the nut making them more difficult to remove and possibly damaging the threads a simple task that saves time in the long run

The other job was to clean all the rust of any exposed threads that needed to be undone and spray them with penetrating oil, the reason being to stop any of the rust being dragged into the nut making them more difficult to remove and possibly damaging the threads a simple task that saves time in the long run

#85

Right then i'd best get some more done on this engine, After a bad start to the year with a family bereavement then replacing the rear quarter on my other S i use as a daily and for sprinting/hillclimbs which some hero T boned me a 100yrds from garage, the next thing the competition season was on us so time flew by and before you know it nearly a year has flown by without me even looking at this project,

' For those that haven't seen this thread i'm basically being a tight arse and seeing if I can build one good engine out of three knackered ones using as many good parts from each as i can and only spending money on what i consider to be essential items,

' So to bring us up to date i have salvaged all the items i need to rebuild the short motor, out of all the components i have checked up to now (discounting damage from destruction) the only two items i have found to be out of Honda's serviceable limits have being the oil control rings which were well outside on two engines and would have caused oil usage and the little ends on Simon's engine which i post a video up when i figure out how to do it, because i am using a mixture of rotating parts from all three engines these will be sent to be balanced as a precaution and what i consider to be essential on a high revving engine,

So that's crank, rods, pistons, flywheel. harmonic balancer. timing chain gear. crank senor phasing wheel and clutch,

' Now it's on to the cylinder heads, this is the first time i have had a good look at the one of Simons apart from a quick glace at No 4 where the rod failed which i could clearly see had bent the valves, this time after digging them all out of the shed is that the electrode on No 2 plug had burned away so was this engine suffering from a vibration from an incomplete burn on one cylinder which caused the all ready worn little ends to shatter, you can see the different burn on the colour of the valve heads compared to the next chamber

back to inspecting the heads to see what i can use catch you later

' For those that haven't seen this thread i'm basically being a tight arse and seeing if I can build one good engine out of three knackered ones using as many good parts from each as i can and only spending money on what i consider to be essential items,

' So to bring us up to date i have salvaged all the items i need to rebuild the short motor, out of all the components i have checked up to now (discounting damage from destruction) the only two items i have found to be out of Honda's serviceable limits have being the oil control rings which were well outside on two engines and would have caused oil usage and the little ends on Simon's engine which i post a video up when i figure out how to do it, because i am using a mixture of rotating parts from all three engines these will be sent to be balanced as a precaution and what i consider to be essential on a high revving engine,

So that's crank, rods, pistons, flywheel. harmonic balancer. timing chain gear. crank senor phasing wheel and clutch,

' Now it's on to the cylinder heads, this is the first time i have had a good look at the one of Simons apart from a quick glace at No 4 where the rod failed which i could clearly see had bent the valves, this time after digging them all out of the shed is that the electrode on No 2 plug had burned away so was this engine suffering from a vibration from an incomplete burn on one cylinder which caused the all ready worn little ends to shatter, you can see the different burn on the colour of the valve heads compared to the next chamber

back to inspecting the heads to see what i can use catch you later

#89

It may not have thrown a light as it was being caned around Spa also it might not have cause a miss fire just an incomplete burn so that cylinder would have produced less power and caused a small imbalance in the engine, judging by the different colours in the two chambers it had run like that for a few laps,

#90

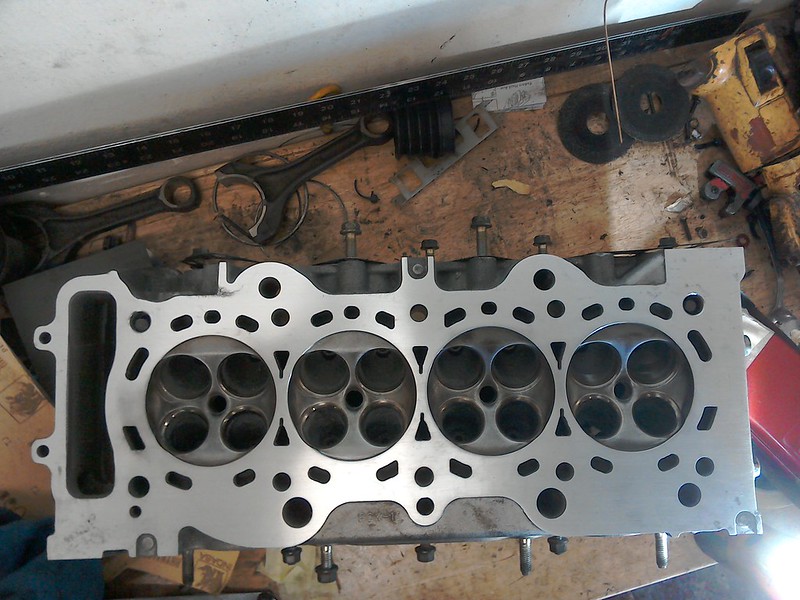

Checked over the heads and the first one Simon's old head had the bent valves on cyl 4, after removing said valves it was found to have damaged a valve guide,

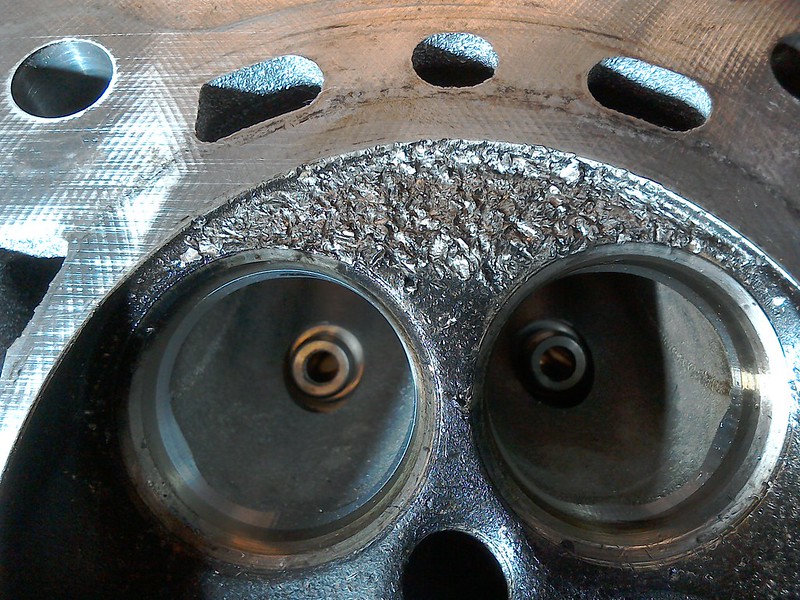

Then onto the 2nd head which had suffered det and the rings had escaped and battered the head and valve seats

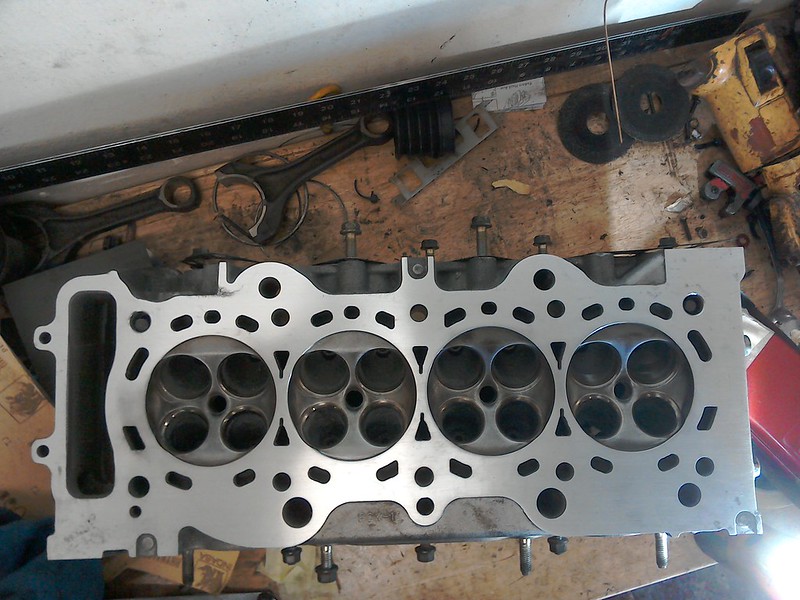

Both of these heads are salvageable at a good machine shop but as this is a budget build and after checking it over i decided to go with Toms old head and a mixture of the best valves from all three, so after cleaning it up i checked it with a straight edge and it was good to go

Now on to the laborious task of hand lapping in the valves with fine lapping paste, this can take minutes or hours depending on the state of the seats after this the valves are matched to each seat so they must be marked as such till they are secured back in place with the springs and retainers,

We are looking for a nice grey ring around the valve and seat,

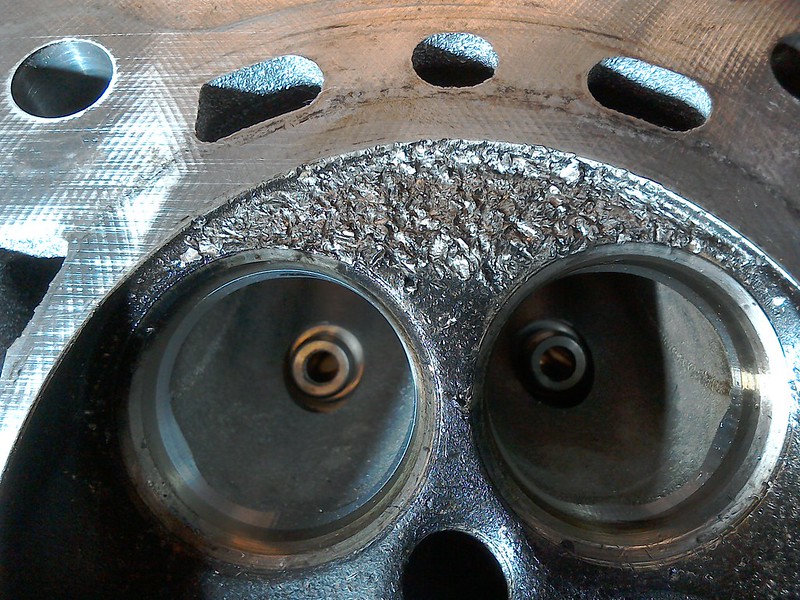

what we don't want are pit marks left in the valve or seat and must keep lapping until all marks have gone if you look close at this seat about 5 to the hour you can just make out a small pit mark which must be removed before moving on to the next valve time spent here reaps rewards later,

and after another session with the lapping paste

Then after a few hours we should end up with a nice clean head with perfect gas seals on the valves

Just got to wait for the up-rated retainers before i can build it up (which i forgot to order )

Then onto the 2nd head which had suffered det and the rings had escaped and battered the head and valve seats

Both of these heads are salvageable at a good machine shop but as this is a budget build and after checking it over i decided to go with Toms old head and a mixture of the best valves from all three, so after cleaning it up i checked it with a straight edge and it was good to go

Now on to the laborious task of hand lapping in the valves with fine lapping paste, this can take minutes or hours depending on the state of the seats after this the valves are matched to each seat so they must be marked as such till they are secured back in place with the springs and retainers,

We are looking for a nice grey ring around the valve and seat,

what we don't want are pit marks left in the valve or seat and must keep lapping until all marks have gone if you look close at this seat about 5 to the hour you can just make out a small pit mark which must be removed before moving on to the next valve time spent here reaps rewards later,

and after another session with the lapping paste

Then after a few hours we should end up with a nice clean head with perfect gas seals on the valves

Just got to wait for the up-rated retainers before i can build it up (which i forgot to order )