F24C Long Rod Engine Build 2.4L

#1

Former Sponsor

Thread Starter

Hi everyone,

For a long time now, 2.4L stroker kits for the F20c and F22c have been available on the market. This is achieved mainly by using a modified K24 crank from Honda’s 2.4L i-Vtec engines which is a 87mm bore, same as the S2000, with a 99mm stroke. Since the deck height on the F20c and F22c are shorter than the K24, the use of custom made shorter length rods are incorporated to keep the use of stock piston designs. Brian Crower has also marketed a 2.4L stroker kit for the S2000 engine using a different idea. They custom make their own crank with a 97mm stroke and then offer custom sized pistons with bores reaching up to 90 mm to get to 2.4L.

Now, let's break down the S2000 F20/22C bore and stroke along with the K24 motors:

F20C 87mm bore 84mm stroke with a rod/stroke ratio of 1.84:1

F22C 87mm bore 90.7mm stroke with a rod/stroke ratio of 1.65:1

K24A 87mm bore 99 mm stroke with a rod/stroke ratio of 1.54:1

As you can see, the longer the stroke of the motor the lower the rod/stroke ratio of the engine is. What does rod/stroke ratio mean? Here is a really good article about rod/stroke ratio by Super Street Magazine: http://www.superstreetonline.com/how...-stroke-ratio/

In this article it explains the differences between Honda engines like the famous B16A or the B18C, along with the K20A and K24. In summary, the best Honda engine rod/stroke ratio is our very own F20c with a 1.84:1, beating the B16A's 1.74:1

Now back to the 2.4L stroker kits for F20/22 engine block. Over the years we’ve seen some 2.4L F series engines with massive compression problems and oil burning issues. Of course, not every one engine is the same, and everything can always be blamed on the prior engine builder. I find this to be kind of a cop-out. In order to fit a 99mm stroke into an F20/22 engine many have had to shorten the 152mm long K24 rod to compensate for the lower deck height of the engine block. This worsens the rod/stroke ratio to approximately a 1.46:1 from 1.54:1, depending what rod lengths these aftermarket stroker kits are using. This creates a higher amount of sidewall load on the piston and cylinder walls. In my opinion I would rather modify the engine block to be taller, which is a non-moving component, than shorten the engine rods, which is a critical moving component within the engine block. S2000 engines already have a decent amount of cylinder wall scoring from wear; so if we are going to stroke an engine block that has technically already been stroked by Honda once (F22c) then we need to increase the deck height of the engine block to be the same as the K24A engine to keep the same rod/stroke ratio Honda intended for this particular crankshaft.

F20/22C deck height is 224mm

K24A deck height is 231.5mm

This is a 7.5mm difference in deck height between the two engine blocks. We want to keep the same rod/stroke ratio of 1.54:1 because I believe this is better for the engine longevity and since Honda designed the K24 block to run this set up we can assume it’s safer for the piston and cylinder walls.

Our mission is to produce a 2.4L engine unlike any other for the F20/22c. We are calling it our Ballade Sports F24C Long Rod engine.

The key components to this setup are the following:

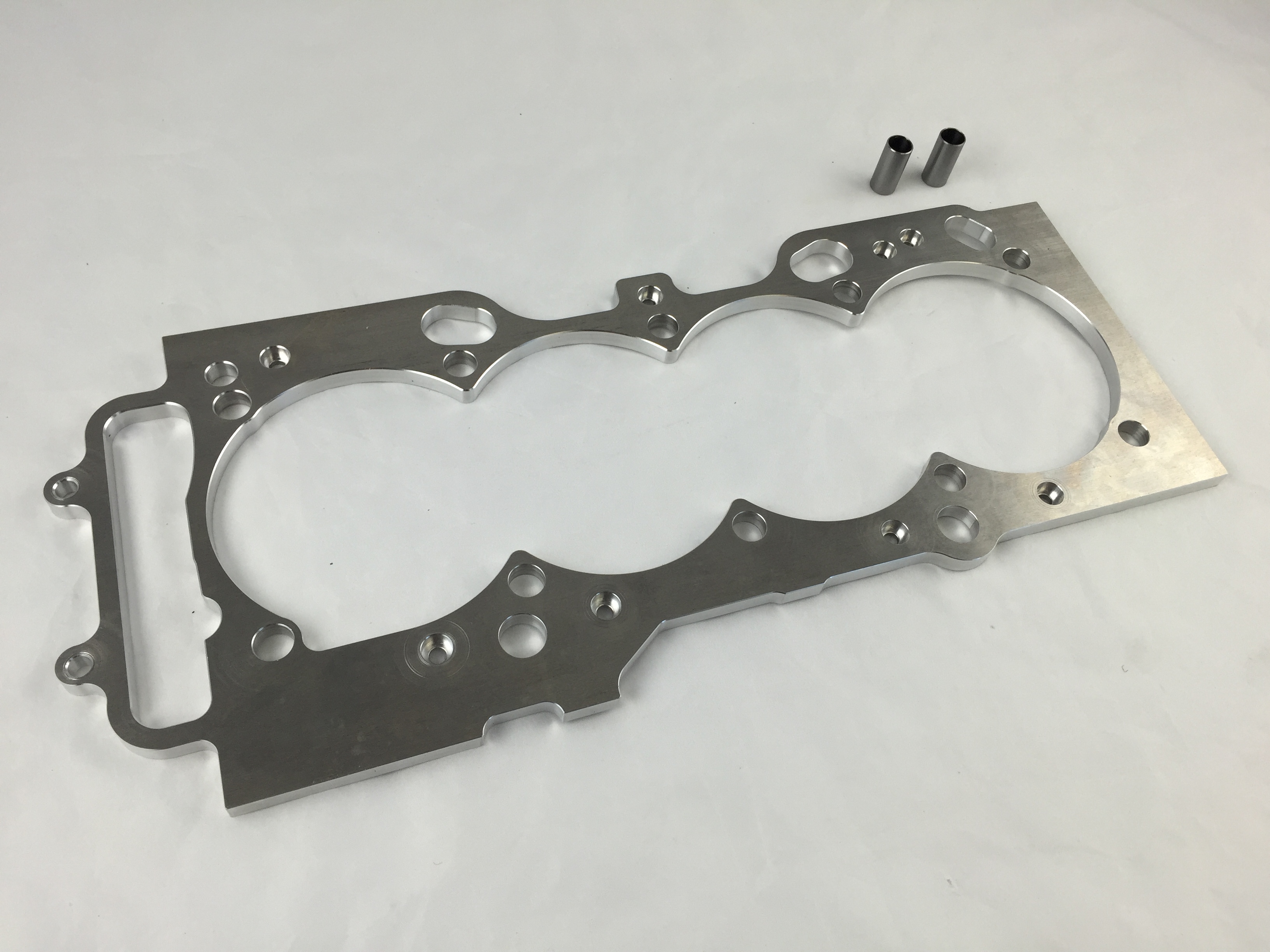

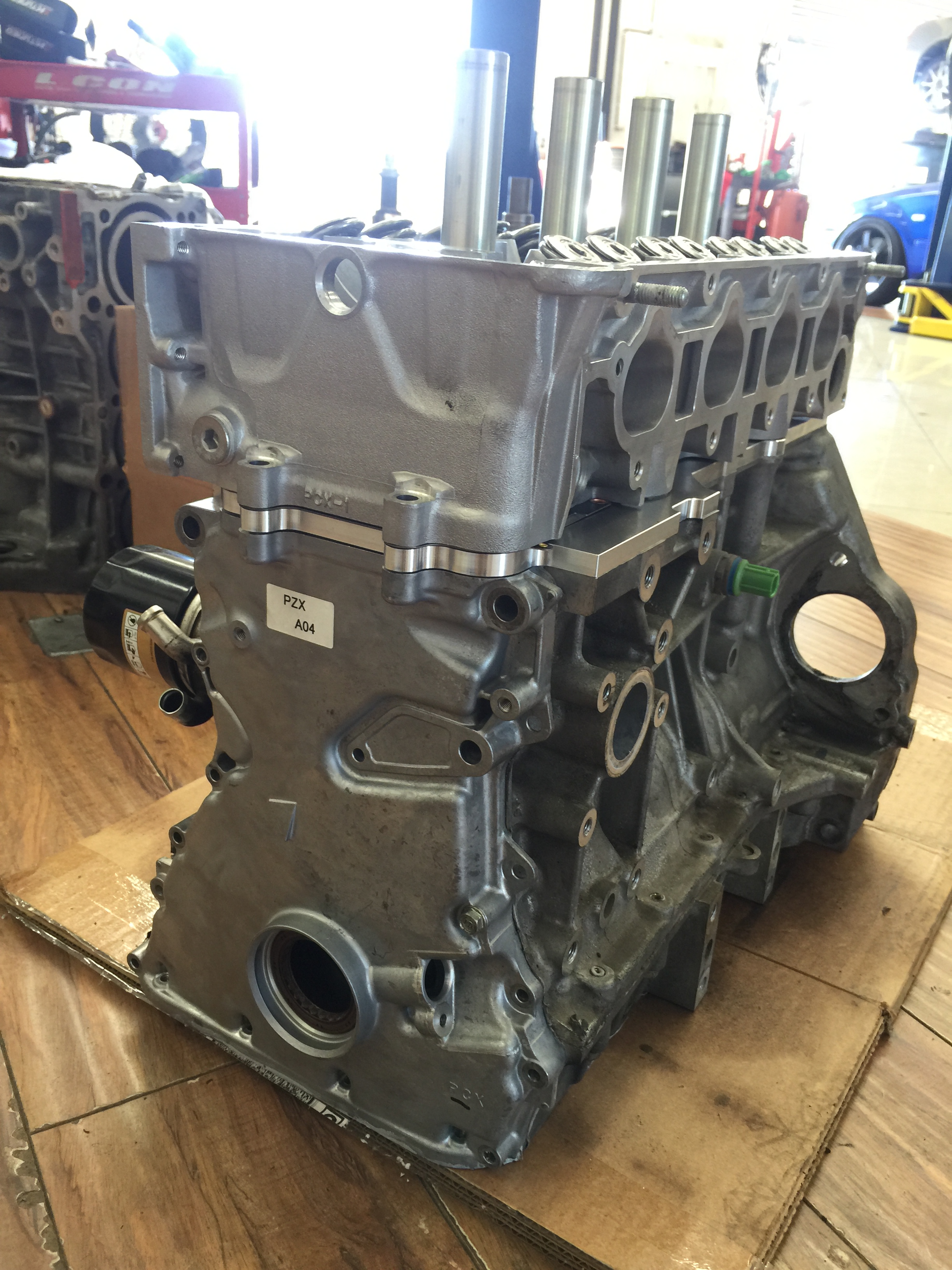

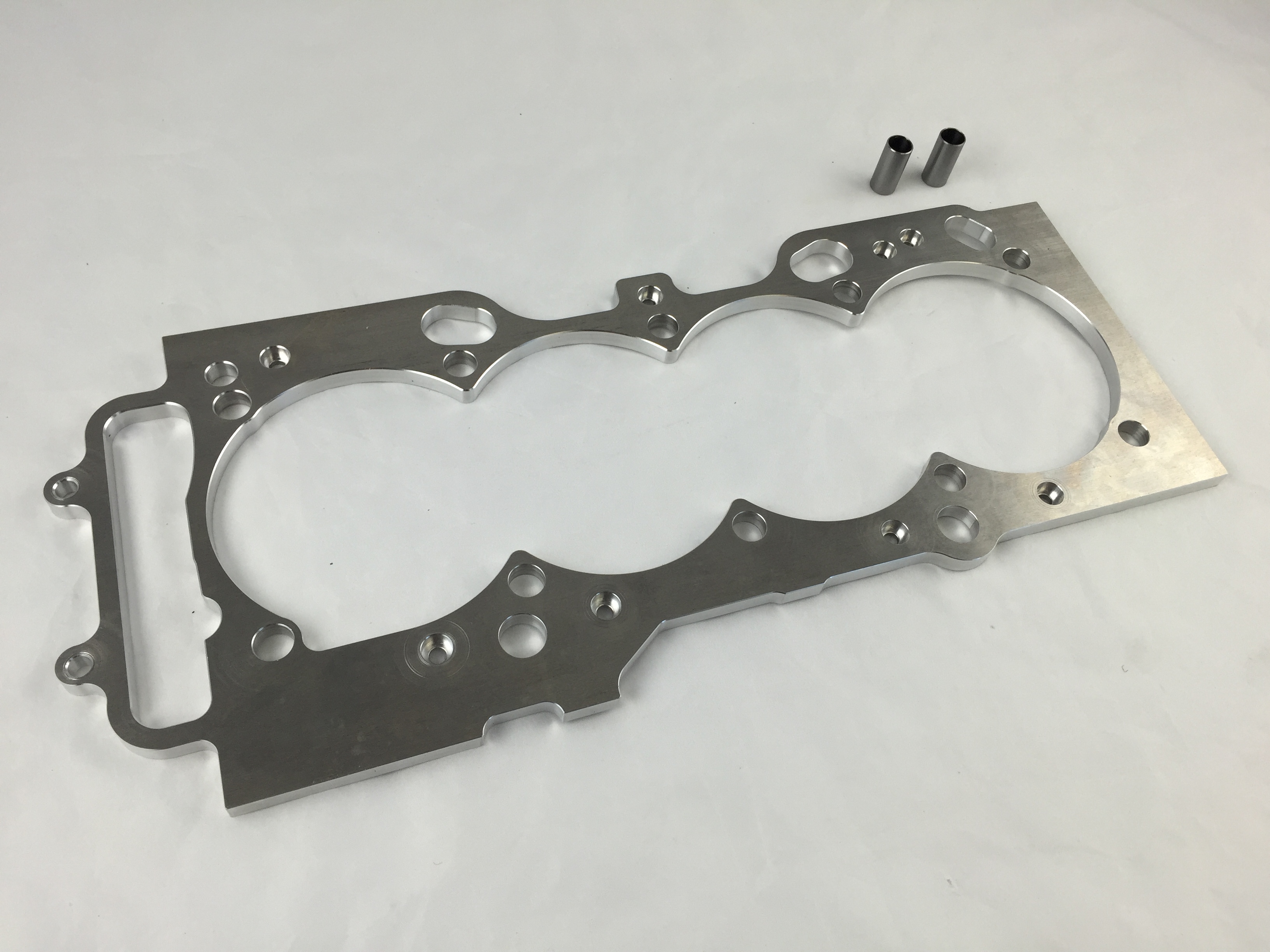

9mm thick F20/22c Deck Plate – Why 9mm and not 7.5mm? This is to ensure enough material is provided for the machine shop to install the taller deck sleeve and deck the cylinder block to the desired deck height measurement.

Longer timing chain – Since the stock S2000 chain isn’t long enough we will need the correct length timing chain and a specialized timing chain tensioner (TCT) for this engine.

Brand New K24A engine crank - modified snout and base to fit the S2000 engine block and enlarged oil journals to match the Ap2 crank.

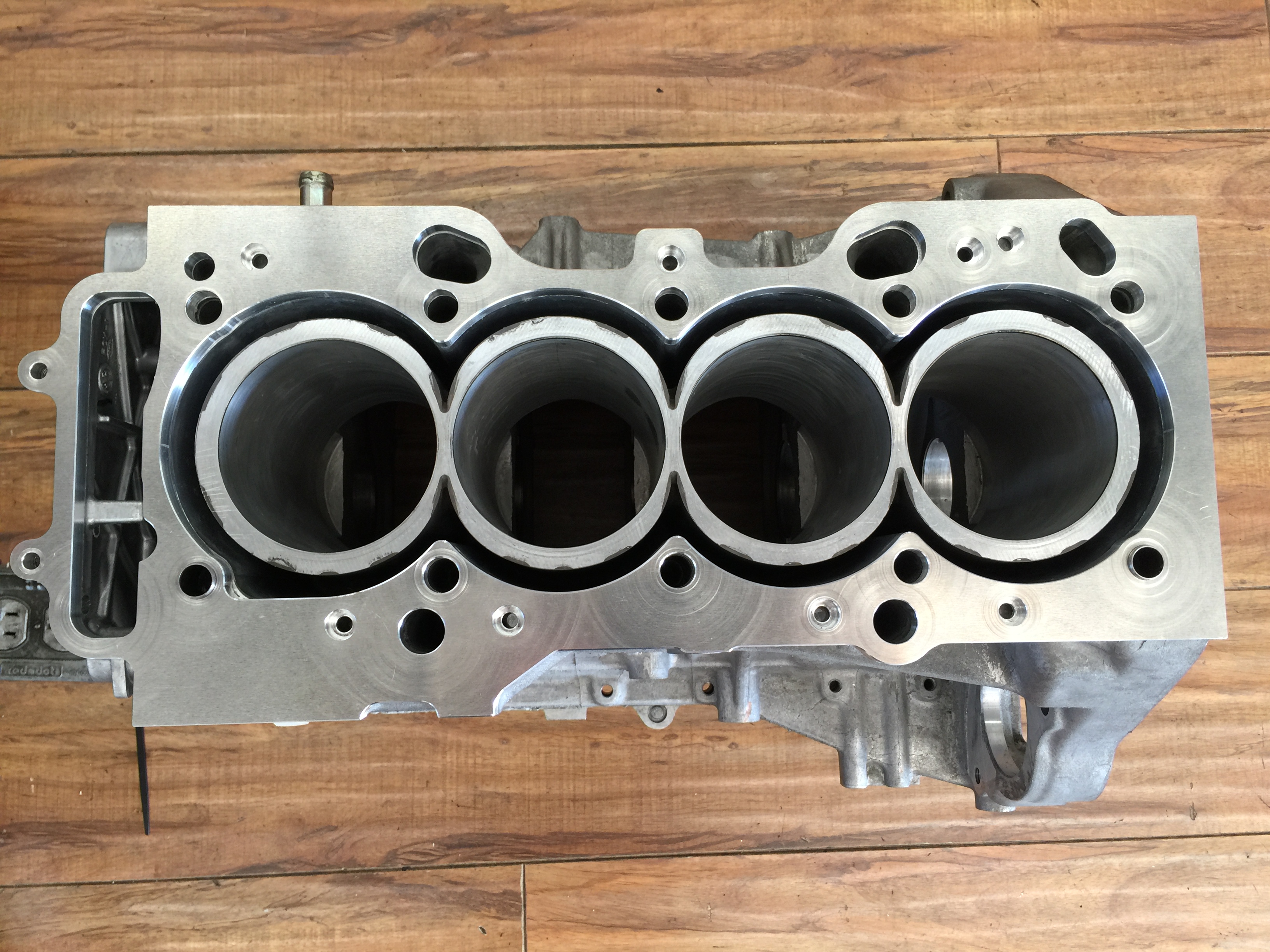

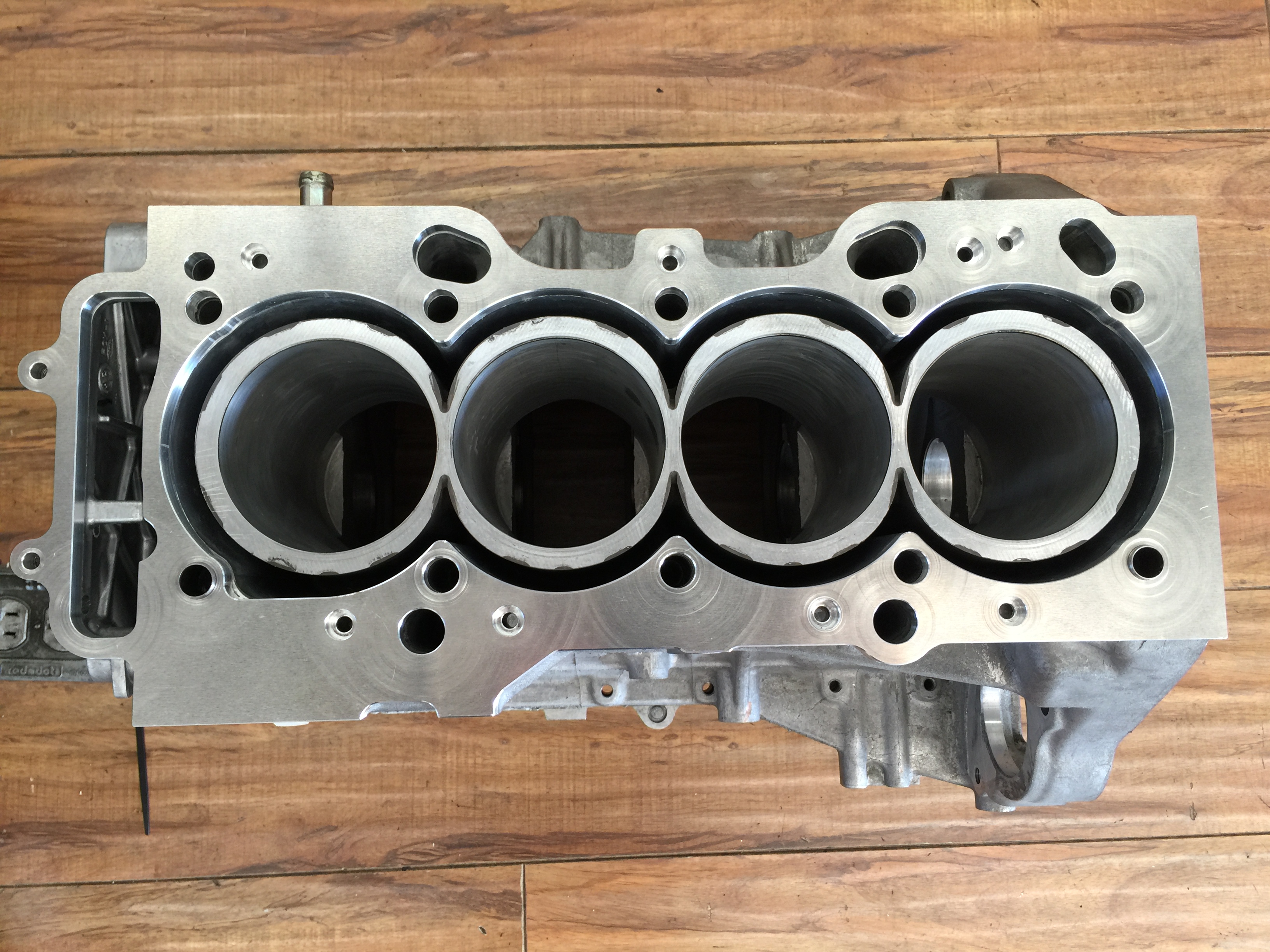

Cast Iron Cylinder Sleeves – To match the increase in deck height via Deck Plate we need to re-sleeve each cylinder to the adjacent height. Our desired deck height is 231.5mm. Same as an actual K24 engine.

Custom length F20/22c head bolts – Since the cylinder head is going to be elevated, we need to have longer head studs/bolts to compensate for the difference in deck height.

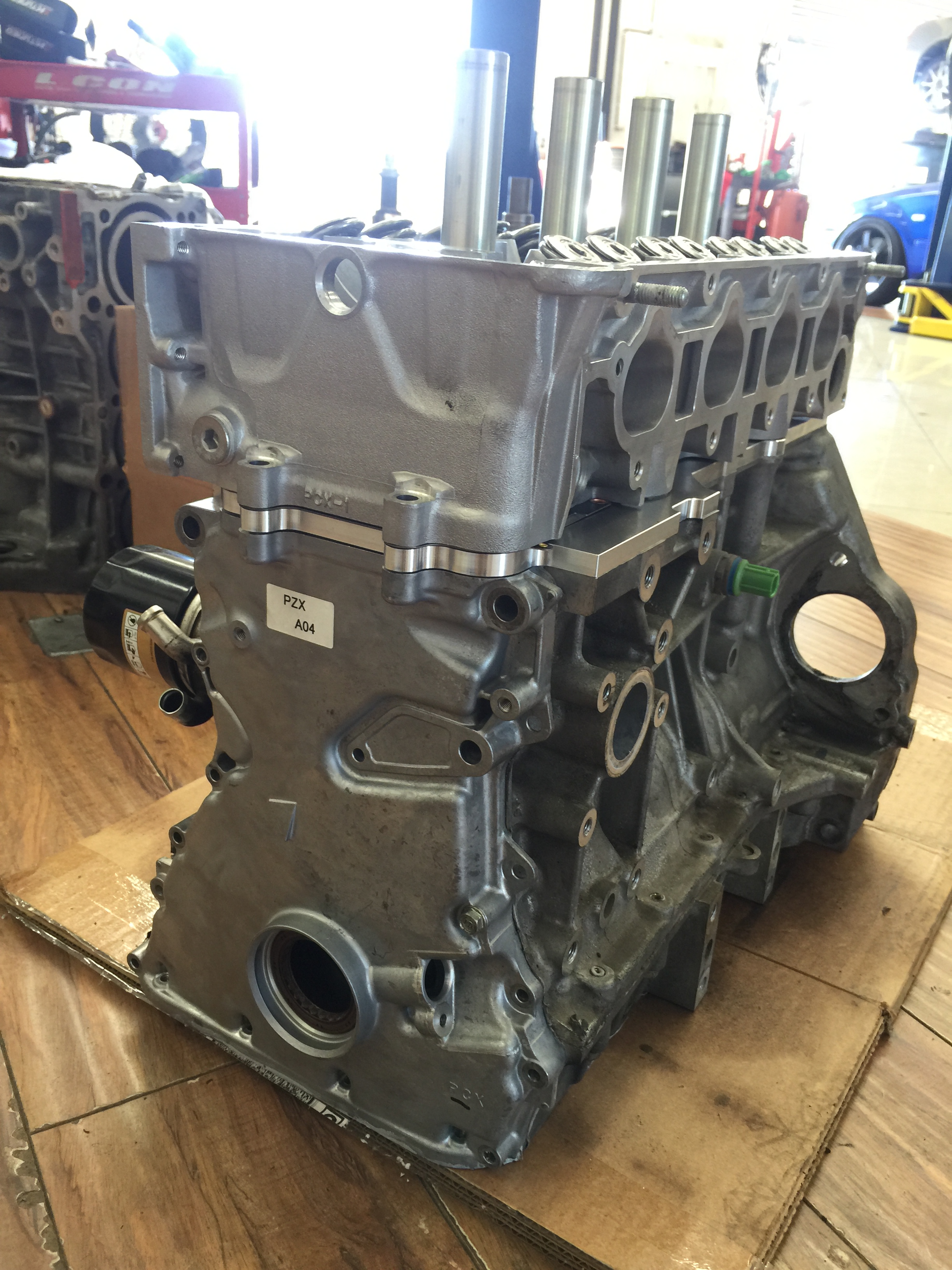

PHASE 1 – THE DECK PLATE

We designed a deck plate specifically for the F20/22C engine block. It covers the outer oil pockets and contours around the water jacket of the cylinder sleeves. It also has added material for the front timing cover. To secure the deck plate to the engine block we are using recessed bolts, in which we had to tap existing holes in the engine block to receive a bolt.

To keep the deck plate from moving we also had to manufacture taller dowel pins. Since the motor is now taller we need the dowel pins going through the head gasket and cylinder head to have adequate length.

To be continued...

For a long time now, 2.4L stroker kits for the F20c and F22c have been available on the market. This is achieved mainly by using a modified K24 crank from Honda’s 2.4L i-Vtec engines which is a 87mm bore, same as the S2000, with a 99mm stroke. Since the deck height on the F20c and F22c are shorter than the K24, the use of custom made shorter length rods are incorporated to keep the use of stock piston designs. Brian Crower has also marketed a 2.4L stroker kit for the S2000 engine using a different idea. They custom make their own crank with a 97mm stroke and then offer custom sized pistons with bores reaching up to 90 mm to get to 2.4L.

Now, let's break down the S2000 F20/22C bore and stroke along with the K24 motors:

F20C 87mm bore 84mm stroke with a rod/stroke ratio of 1.84:1

F22C 87mm bore 90.7mm stroke with a rod/stroke ratio of 1.65:1

K24A 87mm bore 99 mm stroke with a rod/stroke ratio of 1.54:1

As you can see, the longer the stroke of the motor the lower the rod/stroke ratio of the engine is. What does rod/stroke ratio mean? Here is a really good article about rod/stroke ratio by Super Street Magazine: http://www.superstreetonline.com/how...-stroke-ratio/

In this article it explains the differences between Honda engines like the famous B16A or the B18C, along with the K20A and K24. In summary, the best Honda engine rod/stroke ratio is our very own F20c with a 1.84:1, beating the B16A's 1.74:1

Now back to the 2.4L stroker kits for F20/22 engine block. Over the years we’ve seen some 2.4L F series engines with massive compression problems and oil burning issues. Of course, not every one engine is the same, and everything can always be blamed on the prior engine builder. I find this to be kind of a cop-out. In order to fit a 99mm stroke into an F20/22 engine many have had to shorten the 152mm long K24 rod to compensate for the lower deck height of the engine block. This worsens the rod/stroke ratio to approximately a 1.46:1 from 1.54:1, depending what rod lengths these aftermarket stroker kits are using. This creates a higher amount of sidewall load on the piston and cylinder walls. In my opinion I would rather modify the engine block to be taller, which is a non-moving component, than shorten the engine rods, which is a critical moving component within the engine block. S2000 engines already have a decent amount of cylinder wall scoring from wear; so if we are going to stroke an engine block that has technically already been stroked by Honda once (F22c) then we need to increase the deck height of the engine block to be the same as the K24A engine to keep the same rod/stroke ratio Honda intended for this particular crankshaft.

F20/22C deck height is 224mm

K24A deck height is 231.5mm

This is a 7.5mm difference in deck height between the two engine blocks. We want to keep the same rod/stroke ratio of 1.54:1 because I believe this is better for the engine longevity and since Honda designed the K24 block to run this set up we can assume it’s safer for the piston and cylinder walls.

Our mission is to produce a 2.4L engine unlike any other for the F20/22c. We are calling it our Ballade Sports F24C Long Rod engine.

The key components to this setup are the following:

9mm thick F20/22c Deck Plate – Why 9mm and not 7.5mm? This is to ensure enough material is provided for the machine shop to install the taller deck sleeve and deck the cylinder block to the desired deck height measurement.

Longer timing chain – Since the stock S2000 chain isn’t long enough we will need the correct length timing chain and a specialized timing chain tensioner (TCT) for this engine.

Brand New K24A engine crank - modified snout and base to fit the S2000 engine block and enlarged oil journals to match the Ap2 crank.

Cast Iron Cylinder Sleeves – To match the increase in deck height via Deck Plate we need to re-sleeve each cylinder to the adjacent height. Our desired deck height is 231.5mm. Same as an actual K24 engine.

Custom length F20/22c head bolts – Since the cylinder head is going to be elevated, we need to have longer head studs/bolts to compensate for the difference in deck height.

PHASE 1 – THE DECK PLATE

We designed a deck plate specifically for the F20/22C engine block. It covers the outer oil pockets and contours around the water jacket of the cylinder sleeves. It also has added material for the front timing cover. To secure the deck plate to the engine block we are using recessed bolts, in which we had to tap existing holes in the engine block to receive a bolt.

To keep the deck plate from moving we also had to manufacture taller dowel pins. Since the motor is now taller we need the dowel pins going through the head gasket and cylinder head to have adequate length.

To be continued...

#2

Very cool stuff. I can't wait to see the outcome of it all!

#4

Ugh lol. Didn't even read the OP name and then as I got farther n farther down reading, I was like wait wtf! Lol who is this. Then immediately began to be more excited.

Oh n btw yes I have read strokers having problems like stated above, is this the answer to those problems??

Soo because of the deck height being short and having to shorten the rods there was to much side load resulting in case to chamber contamination? And this will fix that.

Hurray up! Lol Jp. Good stuff!

Oh n btw yes I have read strokers having problems like stated above, is this the answer to those problems??

Soo because of the deck height being short and having to shorten the rods there was to much side load resulting in case to chamber contamination? And this will fix that.

Hurray up! Lol Jp. Good stuff!

#6

Registered User

Join Date: Apr 2009

Location: Tampa

Posts: 1,848

Likes: 0

Received 0 Likes

on

0 Posts

Inline Pro seems to have good luck with these engines. A proper builder is key to any engine. My concern is with the deck plate itself. Wouldn't this concept require two head gaskets? One for below the plate and one for above the plate to mate with the cylinder head.

#7

Former Sponsor

Thread Starter

We've already done that . As great as a built K24 can be, this is an attempt to take the good things about a K series and the good things about the F series and merge them together.

Yes, Inlinepro are great at what they have achieved. The main focus on this engine build is reliability, not power. The power and torque increase will take care of itself. We want to see this motor go 200k miles. The idea is to use 90% OEM factory Honda Parts. Crank, rods, pistons. We have plans on making this a production engine in the future. Reliable and powerful.

Believe me, we also have concerns about this new project. That is why we are going to test this for a long time before ever being released to the public. We plan to use one head gasket. We cannot put one in between the deck plate and the sleeves. We will be trying a few different methods to seal the deck plate from oil and water. The sleeves will be taller to match the deck. Engine block is already being sleeved so stay tuned for the next updates.

Believe me, we also have concerns about this new project. That is why we are going to test this for a long time before ever being released to the public. We plan to use one head gasket. We cannot put one in between the deck plate and the sleeves. We will be trying a few different methods to seal the deck plate from oil and water. The sleeves will be taller to match the deck. Engine block is already being sleeved so stay tuned for the next updates.

Trending Topics

#8

Member

This looks good.

And being Ballade I'm sure it will be done properly unlike some of the chancers building engines on here, making bold claims and having flashy adverts.

The key bit is you plan to endurance test it.

I was also interested in how you will seal either side of the deck plate.

And being Ballade I'm sure it will be done properly unlike some of the chancers building engines on here, making bold claims and having flashy adverts.

The key bit is you plan to endurance test it.

I was also interested in how you will seal either side of the deck plate.

#9

Registered User

Join Date: Sep 2005

Location: Racine, Wisconsin

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

Very excited about this project. Adding FI to the S2000 takes away too much of the cars character IMO, and a 2.4 liter short rod build had me worried about engine life.

I am curious if it is difficult or not to source a chain that will be reliable as the OEM piece, but be longer for this build.

I am curious if it is difficult or not to source a chain that will be reliable as the OEM piece, but be longer for this build.