My science of speed fuel pump wire kit just melted my connector

#1

Thread Starter

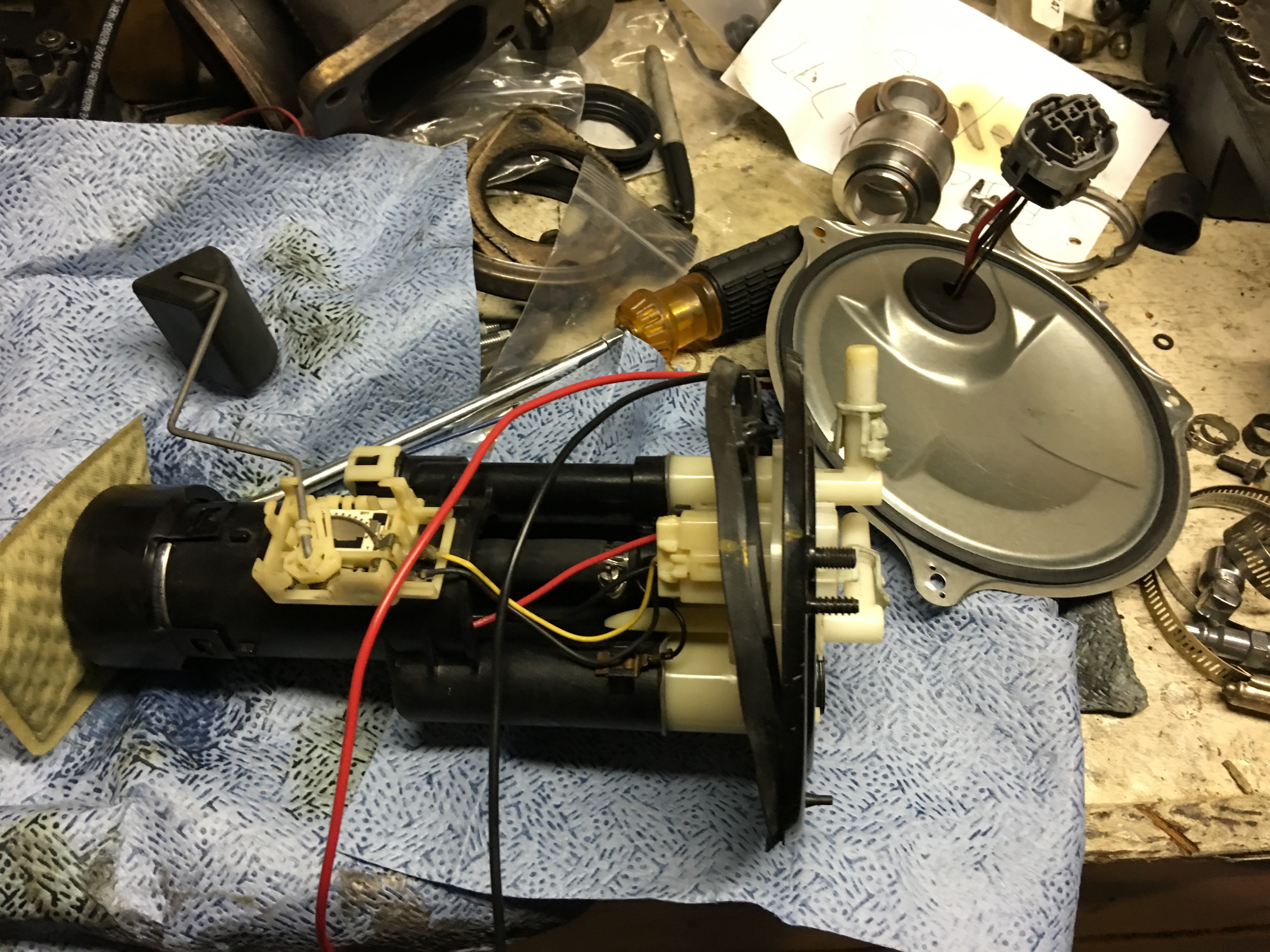

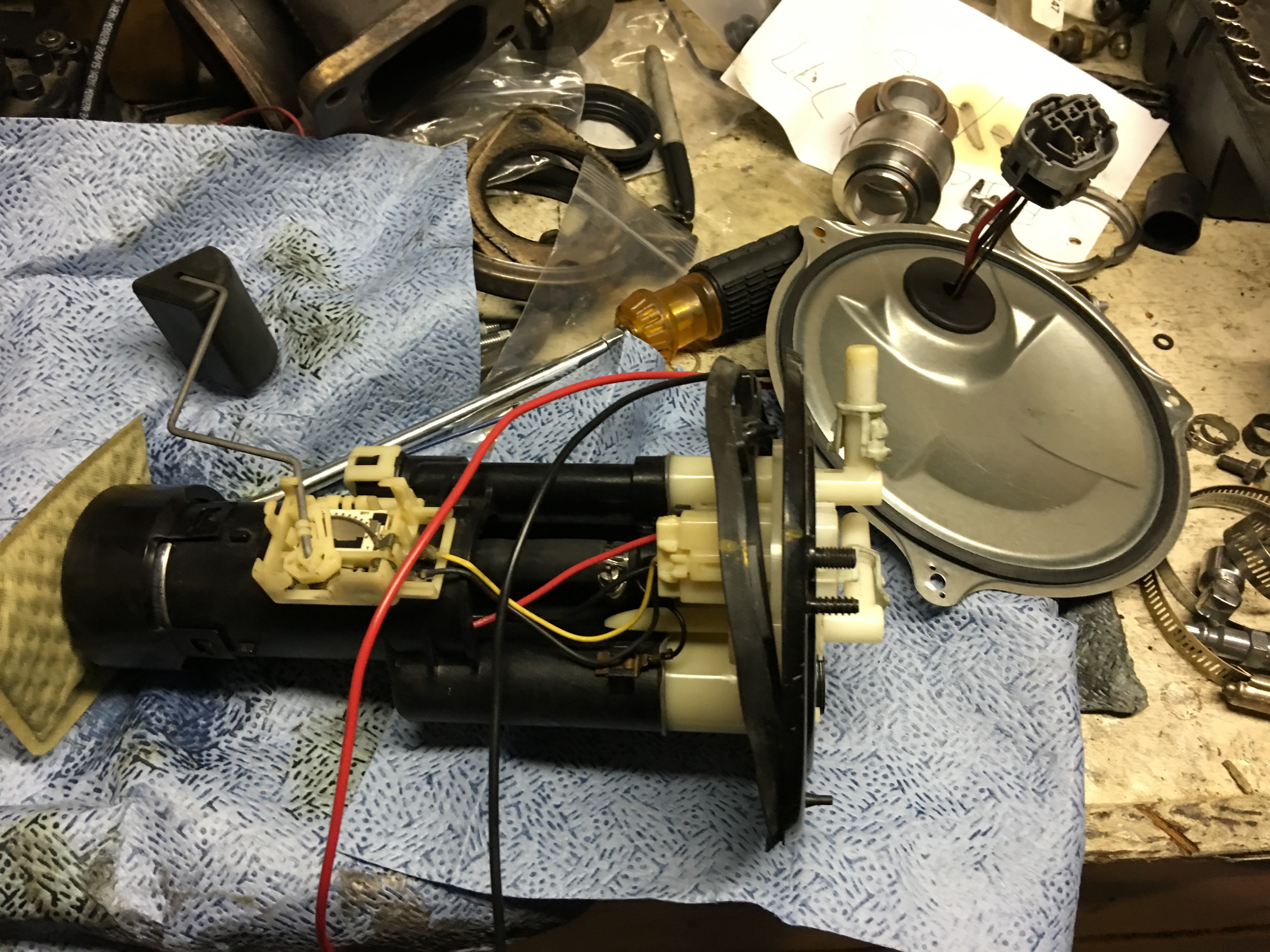

Well my car is down again but this time its because of the science of speed fuel pump wiring. I'm running the ptuning gtx3076r kit making 588whp. I'm running the science of speed walbro e85 450 fuel pump with the sos walbro 450 install kit and the sos fuel pump wiring kit. This setup has been reliable for the past few years at over 600whp. But my car yesterday would not start and i notice i had no fuel pressure. So i had to tow my car home. I check everything from all the fuses to all the relays and wiring and still no fuel pressure. I even plugged in my spare aem ems and still no fuel pressure so i knew there was something wrong with the fuel pump or pump hanger assemble. As i tried to unplug the factory fuel pump hanger plug i notice no mater how hard i pulled i could not get it off. I had to violently pry the plug off the fuel pump housing. turns out that the factory plug melted. You can also see that the pins that the sos kit supply got way to hot and are burnt up which melted the plug. The sos fuel pump wiring kit runs a much thicker gauge wire into the factory plug but they supply factory pins in order to repin the thicker gauge wire into the factory fuel pump housing plug. The weakest link in the fuel pump wiring is not the wiring itself but its the actual pins. Looks like the walbro 450 pump draw too much power for the factory fuel pump housing plug pins. so it all melted.

Anyone else have this problem?

melted fuel pump housing plug

melted plug with the sos repined wiring all black from getting too hot.

Anyone else have this problem?

melted fuel pump housing plug

melted plug with the sos repined wiring all black from getting too hot.

#2

Could you show a picture of the depinned terminal connectors? The new ones that sos provided.

Was just wondering if the hot spot was the connection between the two pins or maybe from a bad crimp.

Was just wondering if the hot spot was the connection between the two pins or maybe from a bad crimp.

#3

I also would like to see the terminal depinned. It looks like from the last photo that the wires are frayed out a little, which says bad crimp. It is also only on one side, which I would expect to see it on both if the wires are handling that much current evenly (which is has to).

#4

I just had this same exact problem 3 weeks ago. I do not have the SOS wiring kit, however i have a self made kit that is very much the same.

After tons of research and calling SOS to see if they had this problem, i came up empty handed.

the best solution i came up with is to drill out the power and ground slots for the pump wiring on the oem plug. then insert two female quick connects in the oem pins location. this will allow a bit bigger connection between the hanger pin and the wire.

After tons of research and calling SOS to see if they had this problem, i came up empty handed.

the best solution i came up with is to drill out the power and ground slots for the pump wiring on the oem plug. then insert two female quick connects in the oem pins location. this will allow a bit bigger connection between the hanger pin and the wire.

#5

Thread Starter

i tried to pull the pins out but its pretty melted. But you maybe right that the crimp might not have been perfect. I just called sos and ordered more pins. I bought a fuel pump hanger on ebay with the oem plug just to get the plug. i just hope this wont happen again.

#6

So did sos mention if it was most likely caused by a bad connection/crimp or could you possibly convert to a dual hangar with two lower lphs and be more reliable by not pushing a big one hard?

I guess I'm asking would the dual be a better solution, money set aside you also said it has been like this for awhile so it's weird a crimp just came loose :scratch head:

I guess I'm asking would the dual be a better solution, money set aside you also said it has been like this for awhile so it's weird a crimp just came loose :scratch head:

#7

Community Organizer

I use the hymen reconstruction method when I put larger than stock wire in the factory style pins you can bend the bow spring in the female pin to grip the pins in the bulkhead just be careful plugin it in as the tighter pins can push out the back of the connector. Have you tried running less pressure or are you maxing out the injector duty cycle at lower pressure? with those pumps they should provide enough volume to run stock or slightly lower than stock pressure. I have an idle pressure of 32 psi on the aeromotive 340 pump on id 1000 injectors at 450 whp 65% duty cycle @18 psi on pump with water/meth.

Trending Topics

#8

I had a close issue. What we had discovered is that you must run the same gauge wire all the way directly to the pump. If you run a larger gauge and then connect it to a smaller gauge, then you will get resistance at that connecting point causing this.

#9

Exactly. Anytime I have installed an intank upgraded fuel pump into the OEM location, I have spent the extra 30-60 minutes and $20 bucks to rewire the whole thing.

#10

Im almost certain that the SOS kit uses 14awg wire just like the walbro fuel pump.