DIY Engine swap? Instructions?

#1

Registered User

Thread Starter

Join Date: Sep 2008

Location: Calgary, Alberta

Posts: 487

Likes: 0

Received 0 Likes

on

0 Posts

Does anyone know where a good DIY is to swap out an engine? I thought I saw one on here a while ago but can't seem to find it again. I want to try and start doing this on my own?

#2

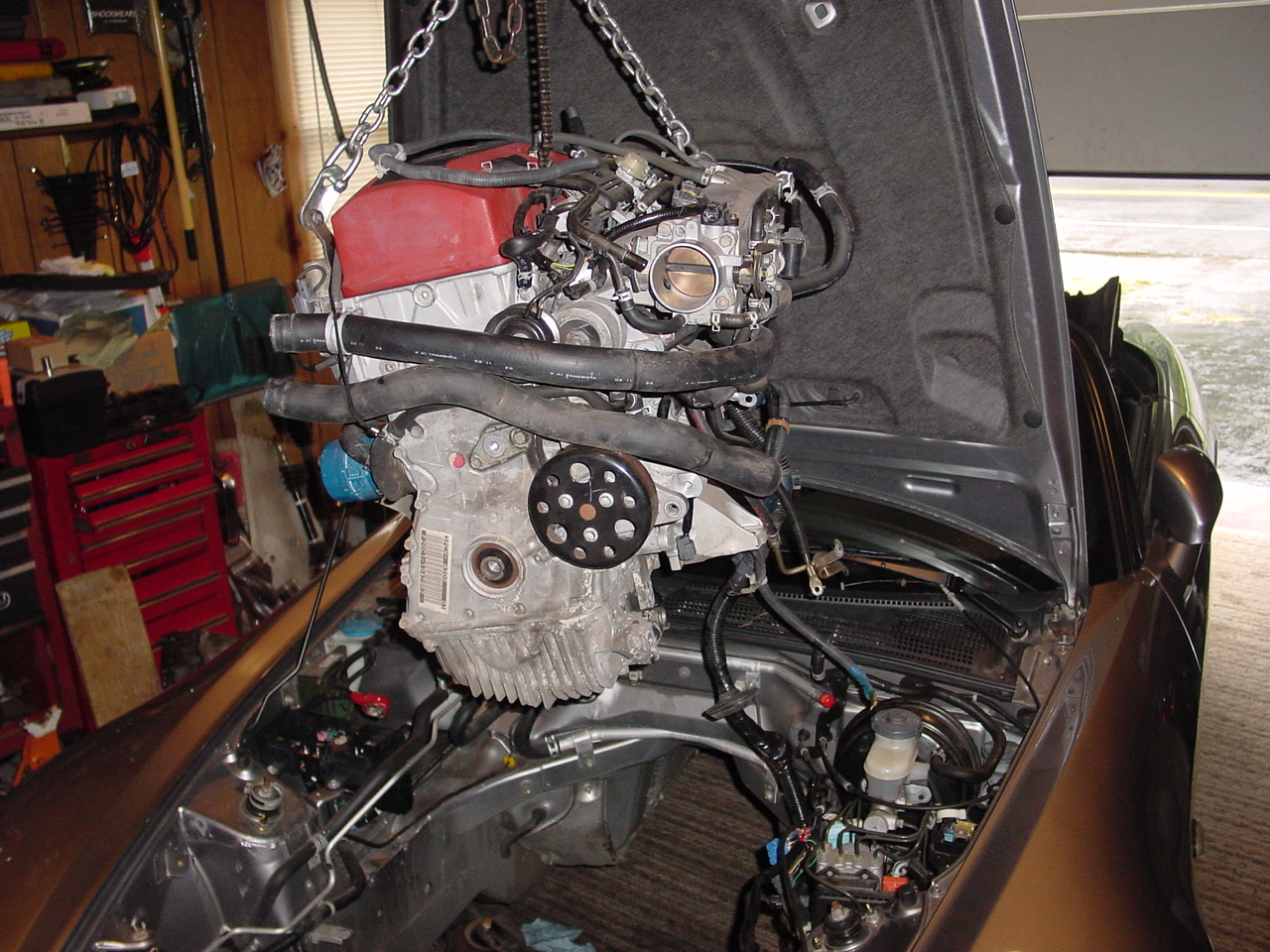

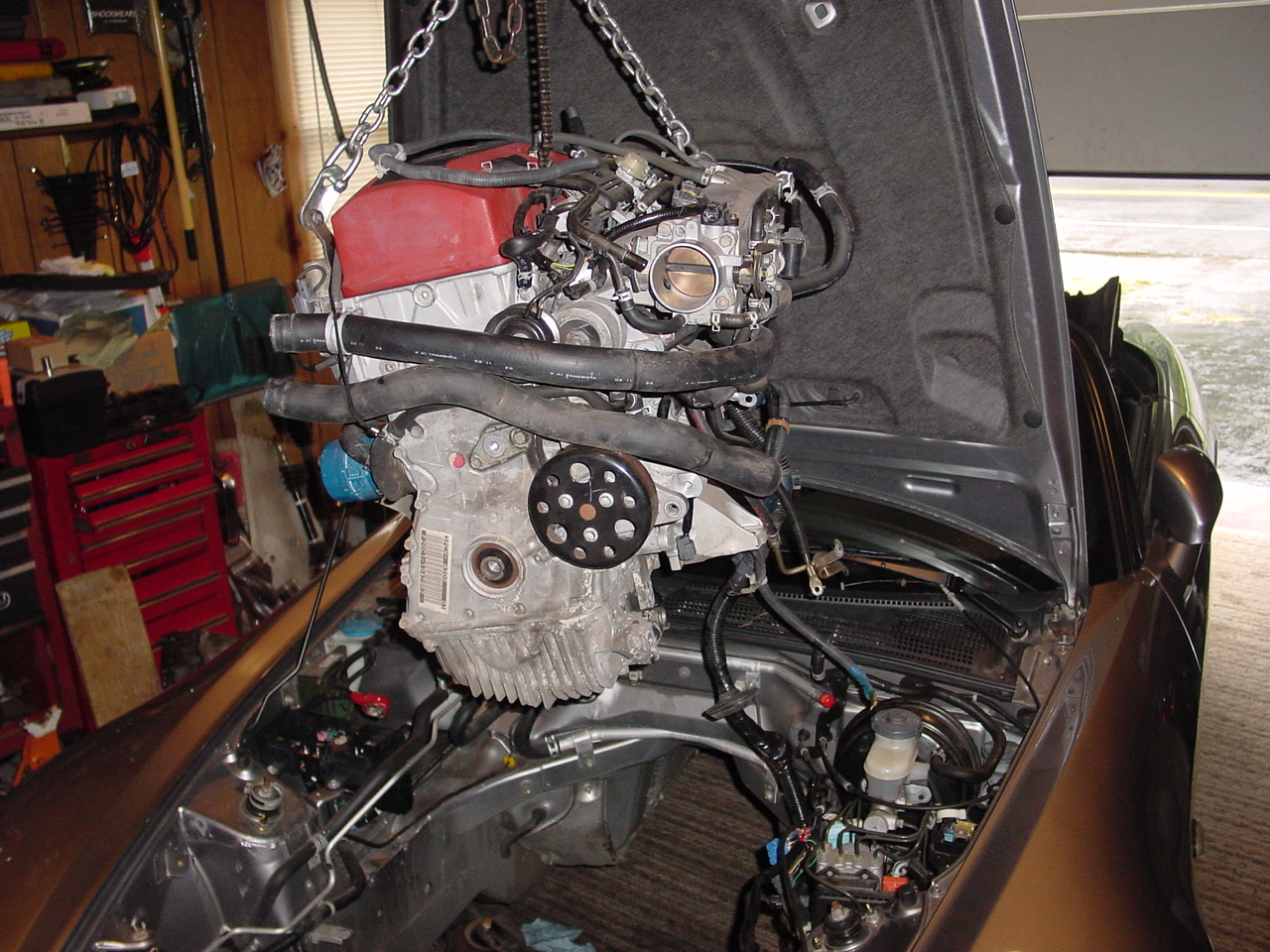

Its a pain in the ass!, Done it twice now.. I pulled both the tranny and engine out through the top.. what makes it a pain is the top tranny bolts and the starter bolts.. but doing it twice ive figured out an easy way to get to the top tranny bolts but it takes 1.5 foot of 1/2 inch drive socket extensions and a swivel on b4 the socket.. take off the header from the bottom 2 bolts take it off from the head 7 bolts i think.. drop it down out of the way to get to the motor mount bolt easier.. take it out but have a jack with a cradle or short piece of 2x6 under the oil pan so u dont dent it or break off the cooling fins.. Drivers side motor mount is more of a pain but its not to bad.. take that off and then the motor should only be held by the jack and tranny/ mount.. go under the car ( use jack stands please so you dont get crushed ) take off the driveshaft from the tranny they are allen head bolts forgot the size, but jack under the tranny to support the weight because now you take off the trany mount ( you need to take off your center console and your shift knob so when you lower ur tranny it dont hang up ) lower the tranny down then go back to the jack under the engine and lower it down.. you should now be able to get to those upper tranny bolts without to much of a problem ( i had an impact so if you dont have one then I dont think your going to break them free ) be carefull beacause ur using 1.5 to 2 foot of extension and a swivel on a impact and they tend to pop off and send crap flying..

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

#3

Registered User

Thread Starter

Join Date: Sep 2008

Location: Calgary, Alberta

Posts: 487

Likes: 0

Received 0 Likes

on

0 Posts

Its a pain in the ass!, Done it twice now.. I pulled both the tranny and engine out through the top.. what makes it a pain is the top tranny bolts and the starter bolts.. but doing it twice ive figured out an easy way to get to the top tranny bolts but it takes 1.5 foot of 1/2 inch drive socket extensions and a swivel on b4 the socket.. take off the header from the bottom 2 bolts take it off from the head 7 bolts i think.. drop it down out of the way to get to the motor mount bolt easier.. take it out but have a jack with a cradle or short piece of 2x6 under the oil pan so u dont dent it or break off the cooling fins.. Drivers side motor mount is more of a pain but its not to bad.. take that off and then the motor should only be held by the jack and tranny/ mount.. go under the car ( use jack stands please so you dont get crushed ) take off the driveshaft from the tranny they are allen head bolts forgot the size, but jack under the tranny to support the weight because now you take off the trany mount ( you need to take off your center console and your shift knob so when you lower ur tranny it dont hang up ) lower the tranny down then go back to the jack under the engine and lower it down.. you should now be able to get to those upper tranny bolts without to much of a problem ( i had an impact so if you dont have one then I dont think your going to break them free ) be carefull beacause ur using 1.5 to 2 foot of extension and a swivel on a impact and they tend to pop off and send crap flying..

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

Wow, I think you just totally put me off of doing this! haha, I don't have any air tools so would you recommend giving this a go with just regular wrenches and ratchets?

#4

Originally Posted by s02k' timestamp='1306351495' post='20614927

Its a pain in the ass!, Done it twice now.. I pulled both the tranny and engine out through the top.. what makes it a pain is the top tranny bolts and the starter bolts.. but doing it twice ive figured out an easy way to get to the top tranny bolts but it takes 1.5 foot of 1/2 inch drive socket extensions and a swivel on b4 the socket.. take off the header from the bottom 2 bolts take it off from the head 7 bolts i think.. drop it down out of the way to get to the motor mount bolt easier.. take it out but have a jack with a cradle or short piece of 2x6 under the oil pan so u dont dent it or break off the cooling fins.. Drivers side motor mount is more of a pain but its not to bad.. take that off and then the motor should only be held by the jack and tranny/ mount.. go under the car ( use jack stands please so you dont get crushed ) take off the driveshaft from the tranny they are allen head bolts forgot the size, but jack under the tranny to support the weight because now you take off the trany mount ( you need to take off your center console and your shift knob so when you lower ur tranny it dont hang up ) lower the tranny down then go back to the jack under the engine and lower it down.. you should now be able to get to those upper tranny bolts without to much of a problem ( i had an impact so if you dont have one then I dont think your going to break them free ) be carefull beacause ur using 1.5 to 2 foot of extension and a swivel on a impact and they tend to pop off and send crap flying..

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

Wow, I think you just totally put me off of doing this! haha, I don't have any air tools so would you recommend giving this a go with just regular wrenches and ratchets?

build the wooden brace thing for the subframe it makes the job much easier, if your not familliar with what im talkin about let me know and il post a picture !!

#6

Registered User

Thread Starter

Join Date: Sep 2008

Location: Calgary, Alberta

Posts: 487

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by skool u' timestamp='1306357434' post='20615409

[quote name='s02k' timestamp='1306351495' post='20614927']

Its a pain in the ass!, Done it twice now.. I pulled both the tranny and engine out through the top.. what makes it a pain is the top tranny bolts and the starter bolts.. but doing it twice ive figured out an easy way to get to the top tranny bolts but it takes 1.5 foot of 1/2 inch drive socket extensions and a swivel on b4 the socket.. take off the header from the bottom 2 bolts take it off from the head 7 bolts i think.. drop it down out of the way to get to the motor mount bolt easier.. take it out but have a jack with a cradle or short piece of 2x6 under the oil pan so u dont dent it or break off the cooling fins.. Drivers side motor mount is more of a pain but its not to bad.. take that off and then the motor should only be held by the jack and tranny/ mount.. go under the car ( use jack stands please so you dont get crushed ) take off the driveshaft from the tranny they are allen head bolts forgot the size, but jack under the tranny to support the weight because now you take off the trany mount ( you need to take off your center console and your shift knob so when you lower ur tranny it dont hang up ) lower the tranny down then go back to the jack under the engine and lower it down.. you should now be able to get to those upper tranny bolts without to much of a problem ( i had an impact so if you dont have one then I dont think your going to break them free ) be carefull beacause ur using 1.5 to 2 foot of extension and a swivel on a impact and they tend to pop off and send crap flying..

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

Its a pain in the ass!, Done it twice now.. I pulled both the tranny and engine out through the top.. what makes it a pain is the top tranny bolts and the starter bolts.. but doing it twice ive figured out an easy way to get to the top tranny bolts but it takes 1.5 foot of 1/2 inch drive socket extensions and a swivel on b4 the socket.. take off the header from the bottom 2 bolts take it off from the head 7 bolts i think.. drop it down out of the way to get to the motor mount bolt easier.. take it out but have a jack with a cradle or short piece of 2x6 under the oil pan so u dont dent it or break off the cooling fins.. Drivers side motor mount is more of a pain but its not to bad.. take that off and then the motor should only be held by the jack and tranny/ mount.. go under the car ( use jack stands please so you dont get crushed ) take off the driveshaft from the tranny they are allen head bolts forgot the size, but jack under the tranny to support the weight because now you take off the trany mount ( you need to take off your center console and your shift knob so when you lower ur tranny it dont hang up ) lower the tranny down then go back to the jack under the engine and lower it down.. you should now be able to get to those upper tranny bolts without to much of a problem ( i had an impact so if you dont have one then I dont think your going to break them free ) be carefull beacause ur using 1.5 to 2 foot of extension and a swivel on a impact and they tend to pop off and send crap flying..

The starter bolts I used some extensions 3/8 drive and a swivel as well and took the inner bolt out from the top and the outer bolt out from the bottom with just the 3/8 ratchet and a short ext.

Those are the only parts I had a problem with, the rest of the bolts are easy to get to.. oh and I also un hooked the engine wire harness from the ecu and pulled it out the firewall and took it out with the engine/tranny. Also b4 u start be sure to take the battery out of the car

Not sure if this is the way to do this or if there is a better way but I did it in a one stall garage and seemed to work out ok..

Hope this helps

Wow, I think you just totally put me off of doing this! haha, I don't have any air tools so would you recommend giving this a go with just regular wrenches and ratchets?

build the wooden brace thing for the subframe it makes the job much easier, if your not familliar with what im talkin about let me know and il post a picture !!

[/quote]

haha, yeah, I'm going to give it a go, but all I have are basic tools and I'm up for the challenge and am in no rush to get my car back on the road. I'm really more excited to learn to do this on my own.

#7

Like Crank said you can do it with hand tools, the first time I did it I did the top 3 tranny bolts from the top with a 1/2 inch ratchet, it was just a pain in the ass so thats when I did it from the bottom when I put it back together and then again the 2nd time I pulled

Trending Topics

#8

I swapped my engine from a 2.0 to a 2.2.I spent only a few hours a night working on the car and I didn't have any air tools.If you just have a basic tool kit I would recommend doing it your self at home to just about anyone.Its all plug and play, I had fun doing it since it was my first time,I really got to learn a lot more about my car. what I ended up doing was dropping the front sub frame and dropping the engine and trans onto a moving dolly and rolled it out from under the car,and it was a breeze, why pay someone 500 to 1000 dollars to swap your motor when all you need is a floor jack, basic tools, jack stand and engine hoist that you can rent from your auto parts store

#9

Registered User

Thread Starter

Join Date: Sep 2008

Location: Calgary, Alberta

Posts: 487

Likes: 0

Received 0 Likes

on

0 Posts

Does anyone have tranny/engine dolly or device to pull or slide it out once it's dropped from the car? I can't imagine that thing being very light but anyone have a device with wheels or a homemade thing? I remember coming across a guy who made his own I think.

#10

Moderator

I pull the trans first, then pull the engine from the top. Pull it with all hoses and wiring harness attached and its easy. Fish the harness up and out of the car with the engine. When installing, fish the harness back through as you lower the engine. It is too stiff and cannot be fished in or out with the engine in place.