Wait that isn't an F20c

#131

Thanks guys

Just received notice that the 2 boxes of batteries that were missing in my shipment showed up randomly...

They were delay 3 weeks somehow.

Also I have decided after some thought to get one last part machined for the drive train.

This motor coupler will be sandwiched between the two motors where the set screw coupling is located.

Reasons why:

- More rigidity

- It will take the stress off of the bearings

- It will hold the motors together

- It will prevent my death if the coupling were to explode at highway speeds

Unfortunately, as accuracy is imperative here, I will need to get the coupling machined by water jet.

I will see what I can do get it made!

Just received notice that the 2 boxes of batteries that were missing in my shipment showed up randomly...

They were delay 3 weeks somehow.

Also I have decided after some thought to get one last part machined for the drive train.

This motor coupler will be sandwiched between the two motors where the set screw coupling is located.

Reasons why:

- More rigidity

- It will take the stress off of the bearings

- It will hold the motors together

- It will prevent my death if the coupling were to explode at highway speeds

Unfortunately, as accuracy is imperative here, I will need to get the coupling machined by water jet.

I will see what I can do get it made!

#133

Thanks guys

Also I have decided after some thought to get one last part machined for the drive train.

This motor coupler will be sandwiched between the two motors where the set screw coupling is located.

Reasons why:

- More rigidity

- It will take the stress off of the bearings

- It will hold the motors together

- It will prevent my death if the coupling were to explode at highway speeds

Unfortunately, as accuracy is imperative here, I will need to get the coupling machined by water jet.

I will see what I can do get it made!

Also I have decided after some thought to get one last part machined for the drive train.

This motor coupler will be sandwiched between the two motors where the set screw coupling is located.

Reasons why:

- More rigidity

- It will take the stress off of the bearings

- It will hold the motors together

- It will prevent my death if the coupling were to explode at highway speeds

Unfortunately, as accuracy is imperative here, I will need to get the coupling machined by water jet.

I will see what I can do get it made!

#136

#137

I joined the forum just to respond to this build. First of all, I love the ambition for this project.

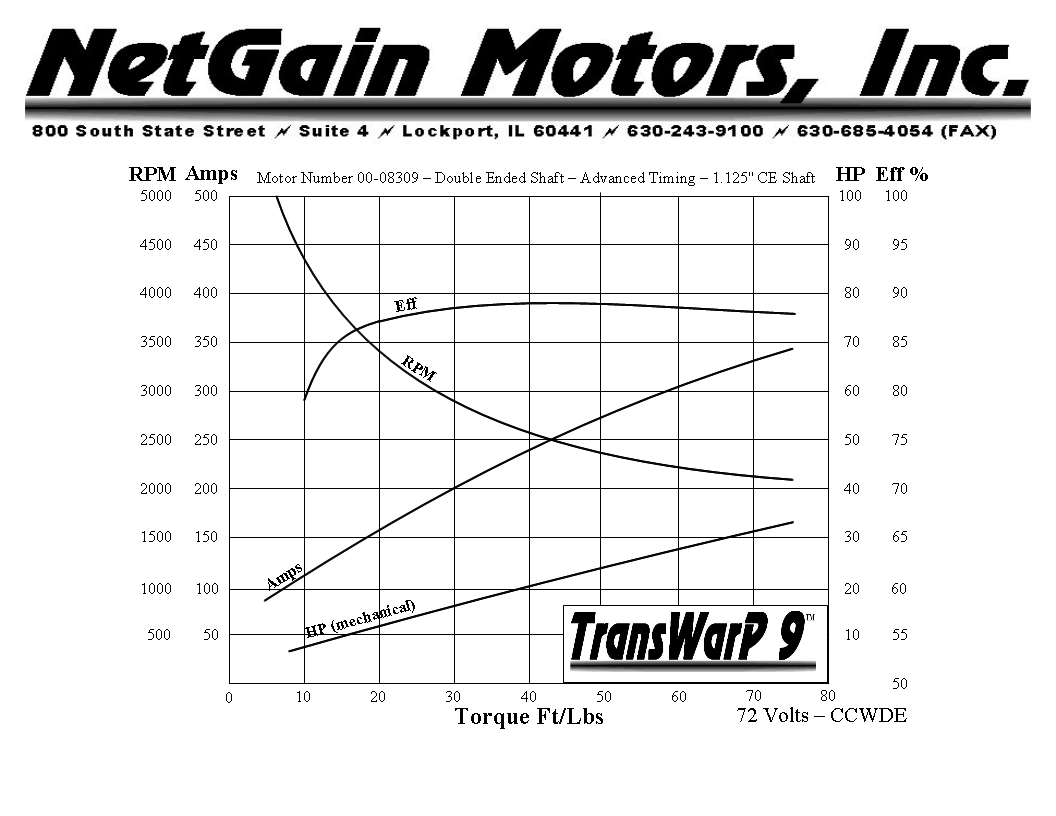

Your motors absolutely, positively, will not be producing 700 horsepower.

Look, I love what you're doing, but the numbers are just wrong. Even with over-volting and dumping tons of current from your Zilla controller, it's not a simple linear power relationship. Just figure in your 700 hp estimation, your motor's efficiency rating, then convert that loss directly into heat. You'll see how ridiculous the claim is. 700 hp is 521,989.91 watts. Assuming your motor is an unrealistically generous 90% efficient, you would still producing 52,198 watts of heat between the two motors! That's the power of over 10 maxed-out home electrical outlets, JUST FOR THE HEAT.

That being said, if you dial back your controller to a reasonable level, I think that car is going to be plenty fast; the instant torque is going to pull some great acceleration times.

Seriously, invest a bit of money in some cooling for those batteries. Even thin aluminum plates that slide in between batteries would help; have them all connect to a larger exterior heatsink. Even if you are talking 2000A output for a brief moment from your controller for brisk acceleration, that is some ridiculous stress on those batteries. If you're running 80 AH (4 parallel), that's right up in the 25C discharge range. A high KWH battery pack like that hitting a critical temp would be absolutely terrifying. Even if it handles 25C discharge, the life of your batteries will absolutely take a hit for doing it. I know RC guys do this stuff with LIPO's but they don't last that long! To put things in perspective, I'm going to be reluctantly running my LIPO EV project at 13C peak, which I still think is too high. I just don't want you to get a crappy cycle life out your your batteries, or worse, have you die in a massive LIPO fire.

And if you insist on stressing those motors the way you plan to, they appear open-case and air cooled. I recommend buying some decent sized bilge blowers to supplement the motor's passive cooling. They are inexpensive, will only require a couple hundred watts to run, and it will reduce your motor temps.

Good luck. I love how you're willing to tackle stuff like this at an early age, and my criticisms are meant to be constructive! That thing is serious business and will stomp the hell out of most petrol cars (if you can get the traction and your drivetrain holds)!

Your motors absolutely, positively, will not be producing 700 horsepower.

Look, I love what you're doing, but the numbers are just wrong. Even with over-volting and dumping tons of current from your Zilla controller, it's not a simple linear power relationship. Just figure in your 700 hp estimation, your motor's efficiency rating, then convert that loss directly into heat. You'll see how ridiculous the claim is. 700 hp is 521,989.91 watts. Assuming your motor is an unrealistically generous 90% efficient, you would still producing 52,198 watts of heat between the two motors! That's the power of over 10 maxed-out home electrical outlets, JUST FOR THE HEAT.

That being said, if you dial back your controller to a reasonable level, I think that car is going to be plenty fast; the instant torque is going to pull some great acceleration times.

Seriously, invest a bit of money in some cooling for those batteries. Even thin aluminum plates that slide in between batteries would help; have them all connect to a larger exterior heatsink. Even if you are talking 2000A output for a brief moment from your controller for brisk acceleration, that is some ridiculous stress on those batteries. If you're running 80 AH (4 parallel), that's right up in the 25C discharge range. A high KWH battery pack like that hitting a critical temp would be absolutely terrifying. Even if it handles 25C discharge, the life of your batteries will absolutely take a hit for doing it. I know RC guys do this stuff with LIPO's but they don't last that long! To put things in perspective, I'm going to be reluctantly running my LIPO EV project at 13C peak, which I still think is too high. I just don't want you to get a crappy cycle life out your your batteries, or worse, have you die in a massive LIPO fire.

And if you insist on stressing those motors the way you plan to, they appear open-case and air cooled. I recommend buying some decent sized bilge blowers to supplement the motor's passive cooling. They are inexpensive, will only require a couple hundred watts to run, and it will reduce your motor temps.

Good luck. I love how you're willing to tackle stuff like this at an early age, and my criticisms are meant to be constructive! That thing is serious business and will stomp the hell out of most petrol cars (if you can get the traction and your drivetrain holds)!

#138

Registered User

Join Date: Apr 2011

Location: Amesbury, MA

Posts: 600

Likes: 0

Received 0 Likes

on

0 Posts

Your motors absolutely, positively, will not be producing 700 horsepower.

Good luck. I love how you're willing to tackle stuff like this at an early age, and my criticisms are meant to be constructive! That thing is serious business and will stomp the hell out of most petrol cars (if you can get the traction and your drivetrain holds)!

Good luck. I love how you're willing to tackle stuff like this at an early age, and my criticisms are meant to be constructive! That thing is serious business and will stomp the hell out of most petrol cars (if you can get the traction and your drivetrain holds)!

Also, just a note from a fellow engineer, The drawing you posted above for your motor mount is missing several dimensions and won't be able to be manufactured accurately (or at all) without the proper dimensions. PM me if you need help with drawings or part design, I'll gladly offer my time and services to help your project.

#139

Registered User

Join Date: Feb 2010

Location: Stamford, CT

Posts: 3,263

Likes: 0

Received 0 Likes

on

0 Posts

Small update!

Decided to have a small 'battery peeling party' last night

Basically ordered pizza, peeled batteries, and watched workaholics all night long.

It was fun, and we were able to knock out ~ 7 boxes / 28 in about 2.5 hrs, they just need to be punched at this point.

4 boxes took me about a week of work every day after school, so ~ 15 hrs. It took a lot longer because I was experimenting and didn't really know the most efficient process at that point.

Dream team

The end result

I also received a couple of parts for my tail light mod. I now have an adjustable brightness, and a difference between brake on / brake off.

Brake Off

Brake On

Some of the pieces of the puzzle, used to dictate the brightness of the tails.

Still need some more electronic components to arrive before sequential tails work.

ballin

Decided to have a small 'battery peeling party' last night

Basically ordered pizza, peeled batteries, and watched workaholics all night long.

It was fun, and we were able to knock out ~ 7 boxes / 28 in about 2.5 hrs, they just need to be punched at this point.

4 boxes took me about a week of work every day after school, so ~ 15 hrs. It took a lot longer because I was experimenting and didn't really know the most efficient process at that point.

Dream team

The end result

I also received a couple of parts for my tail light mod. I now have an adjustable brightness, and a difference between brake on / brake off.

Brake Off

Brake On

Some of the pieces of the puzzle, used to dictate the brightness of the tails.

Still need some more electronic components to arrive before sequential tails work.

ballin

....really ..this is got to be one of the last things I'd ever see anyone do to an S2k,and just when I though i've seen it all ...this shows up

....really ..this is got to be one of the last things I'd ever see anyone do to an S2k,and just when I though i've seen it all ...this shows up