saving4one's build

#11

Thread Starter

The machine shop threw my old ex. guides in a box when I picked up my head, visually they don't look that bad. I'm going to measure them to see how far out of spec they are, hard to believe the amount of play in the most worn one, by eye they all look the same. I'm writing about this issue mostly for the UTH readers, who were interested in what exactly failed in my head. The machine shop owner said it might have been a bad batch of ex. guides from the factory. That would support why only the guides failed and no bent/burnt valves. I was surprised, after seeing/feeling the play with the worst valve, that it was not bent and that it only wore the seat into an oval. I wonder how many other S2000 owners have had this same issue? I also measured my head height after I got it back from the shop - 104.958 mm - which is real close to the service limit, so hopefully this doesn't happen again. Of course I didn't measure it right after I took it off, and I stressed with the shop how I wanted none or .001 milled if it was a must, the shop owner said his guy took about .006 off. Oh well.

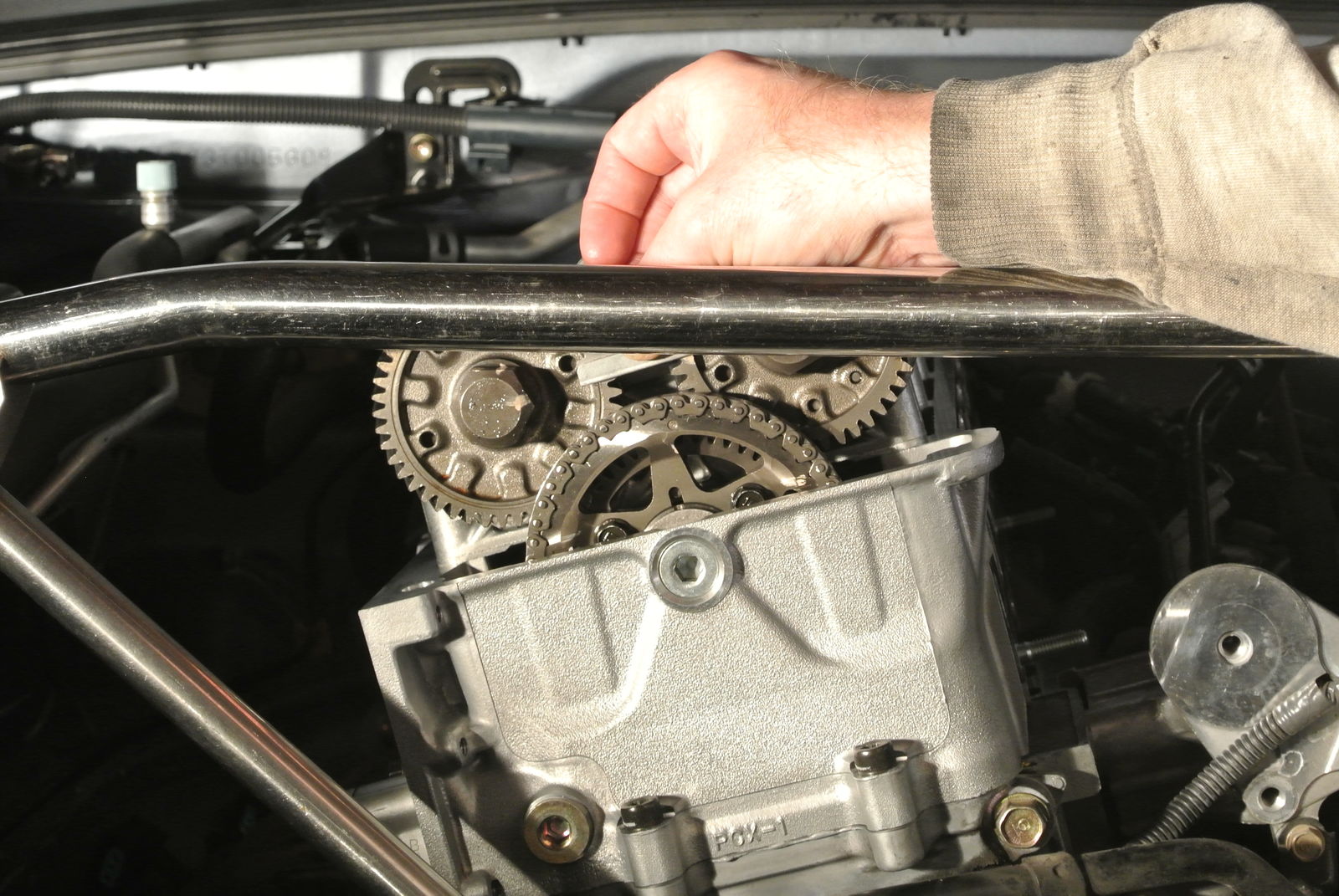

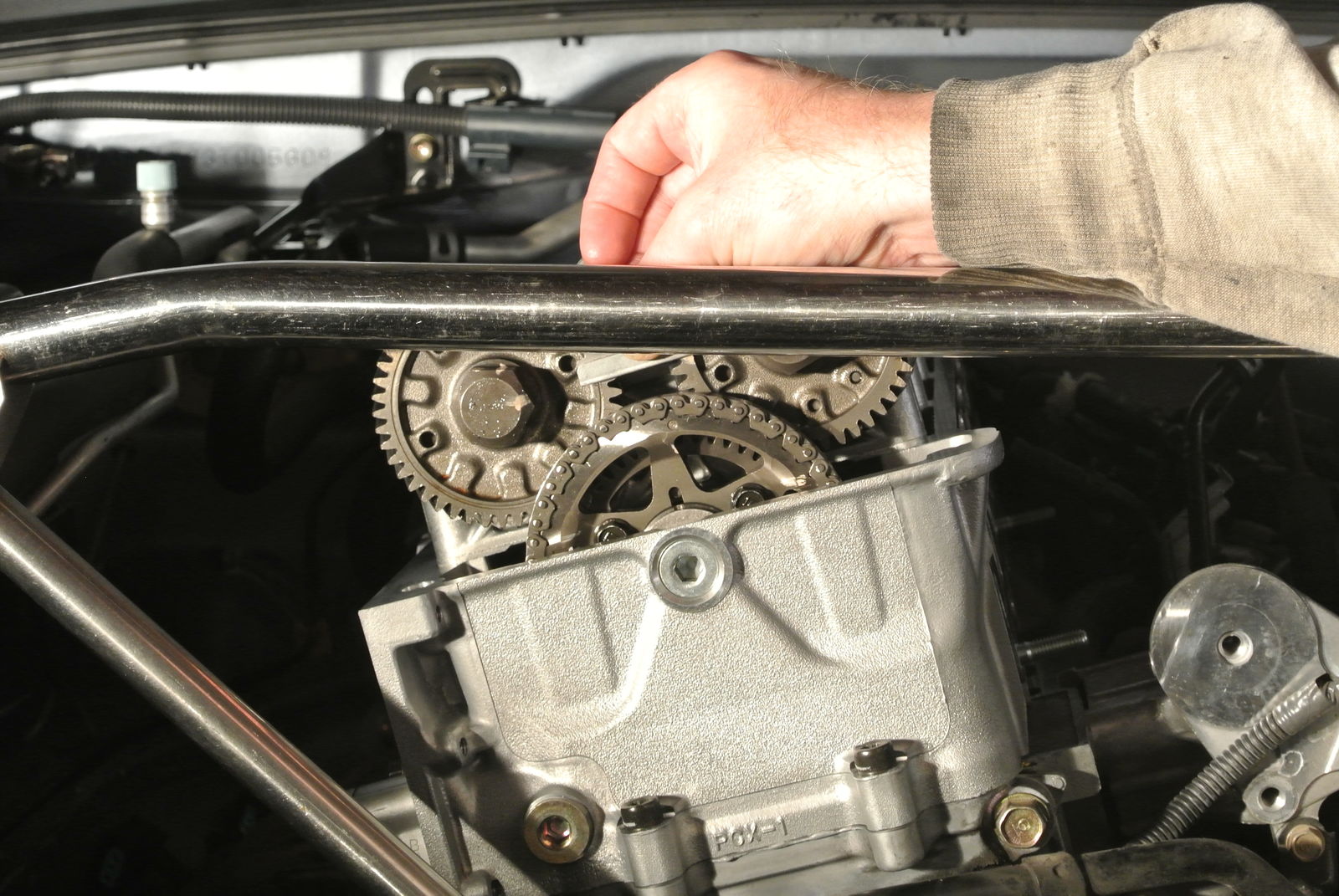

I thought this picture was pretty cool with the flash on but no tripod:

This past Sunday evening I installed the head on the block. Everything went fairly smooth, except for the gasket sealer around the chain case part, worrying weather or not I put enough on to keep it from leaking oil. I torqued all the head bolts (re-used my old ones, very min. stretch) to the initial 22 ft lb and used a paint marker to put a dot on all the bolt heads at 12 o'clock, so I could easily track the rotational position for the next two torque steps. No noise and no problems. Then I bolted that ground wire back up to the back of the head without dropping that bolt again.

Last night I put the chain/idler gear set back in and installed the TCT, which I had already retracted and pinned, what, like 6 weeks ago! At first when I was trying to get the chain back on the gear I was thinking 'This isn't working,' then I held the chain toward the front of the car and slid the gear in from the rear it just slipped on like magic. Thankfully it only took about two minutes of trying to put it on like a bike chain before I figured out the trick. Then I had the timing marks about perfect, but I had to make sure, so I tried to move it one tooth but then it was really off, so I locked it down and after that satisfying 'tink' of the TCT tensioner rod thingy against the chain guide button, my timing marks still looked great. The intake side is a little high, but I'm 99% sure that's exactly how it looked at TDC (crank pulley white mark dead on with case arrow) before I took it apart . Basically, as good as it gets! I really enjoy wrenching when it doesn't become overly frustrating. Good session.

I thought this picture was pretty cool with the flash on but no tripod:

This past Sunday evening I installed the head on the block. Everything went fairly smooth, except for the gasket sealer around the chain case part, worrying weather or not I put enough on to keep it from leaking oil. I torqued all the head bolts (re-used my old ones, very min. stretch) to the initial 22 ft lb and used a paint marker to put a dot on all the bolt heads at 12 o'clock, so I could easily track the rotational position for the next two torque steps. No noise and no problems. Then I bolted that ground wire back up to the back of the head without dropping that bolt again.

Last night I put the chain/idler gear set back in and installed the TCT, which I had already retracted and pinned, what, like 6 weeks ago! At first when I was trying to get the chain back on the gear I was thinking 'This isn't working,' then I held the chain toward the front of the car and slid the gear in from the rear it just slipped on like magic. Thankfully it only took about two minutes of trying to put it on like a bike chain before I figured out the trick. Then I had the timing marks about perfect, but I had to make sure, so I tried to move it one tooth but then it was really off, so I locked it down and after that satisfying 'tink' of the TCT tensioner rod thingy against the chain guide button, my timing marks still looked great. The intake side is a little high, but I'm 99% sure that's exactly how it looked at TDC (crank pulley white mark dead on with case arrow) before I took it apart . Basically, as good as it gets! I really enjoy wrenching when it doesn't become overly frustrating. Good session.

Last edited by saving4one; 11-06-2016 at 10:04 AM.

The following users liked this post:

saving4one (11-06-2016)

#13

Time to clean that layer of dust off

#14

Thread Starter

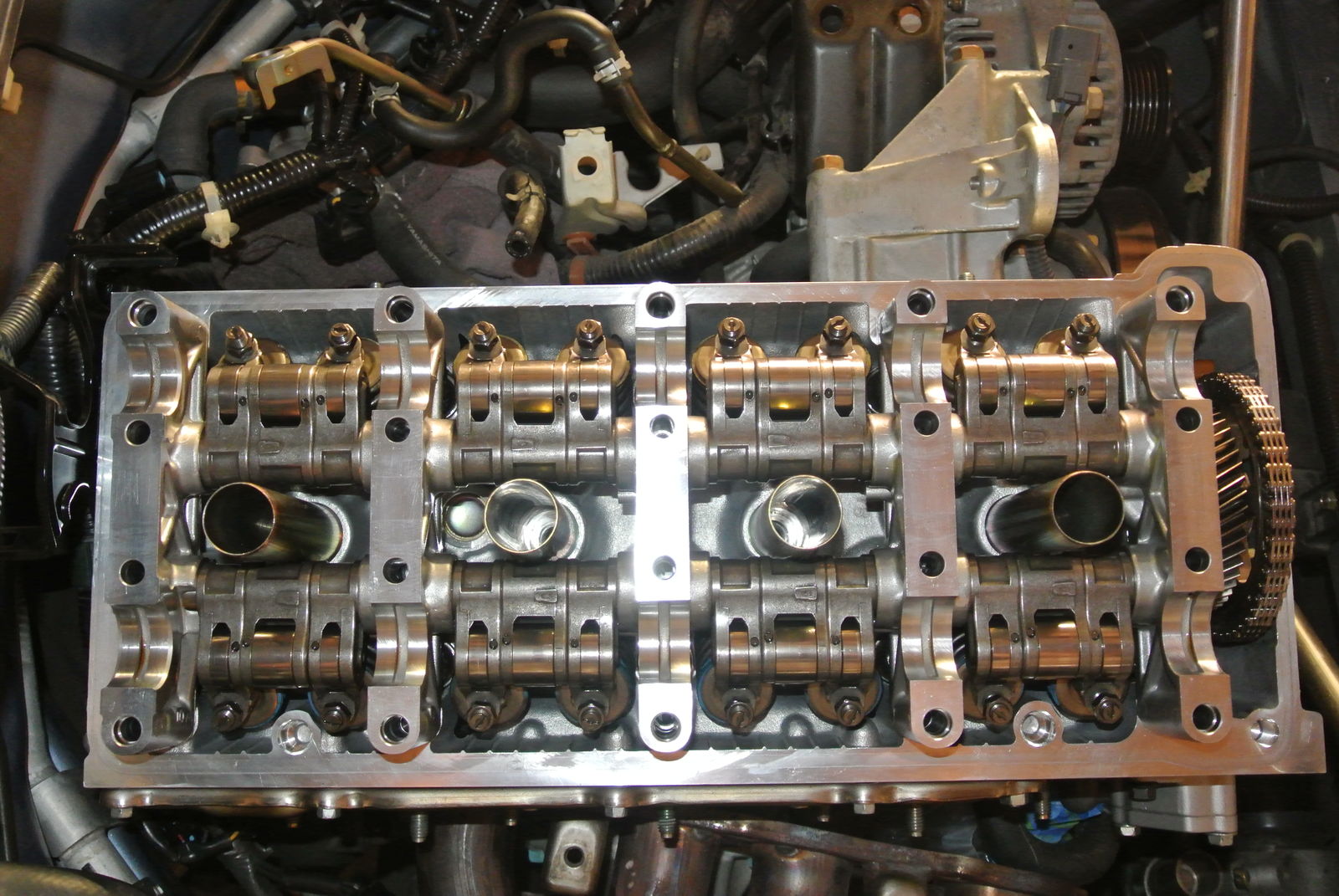

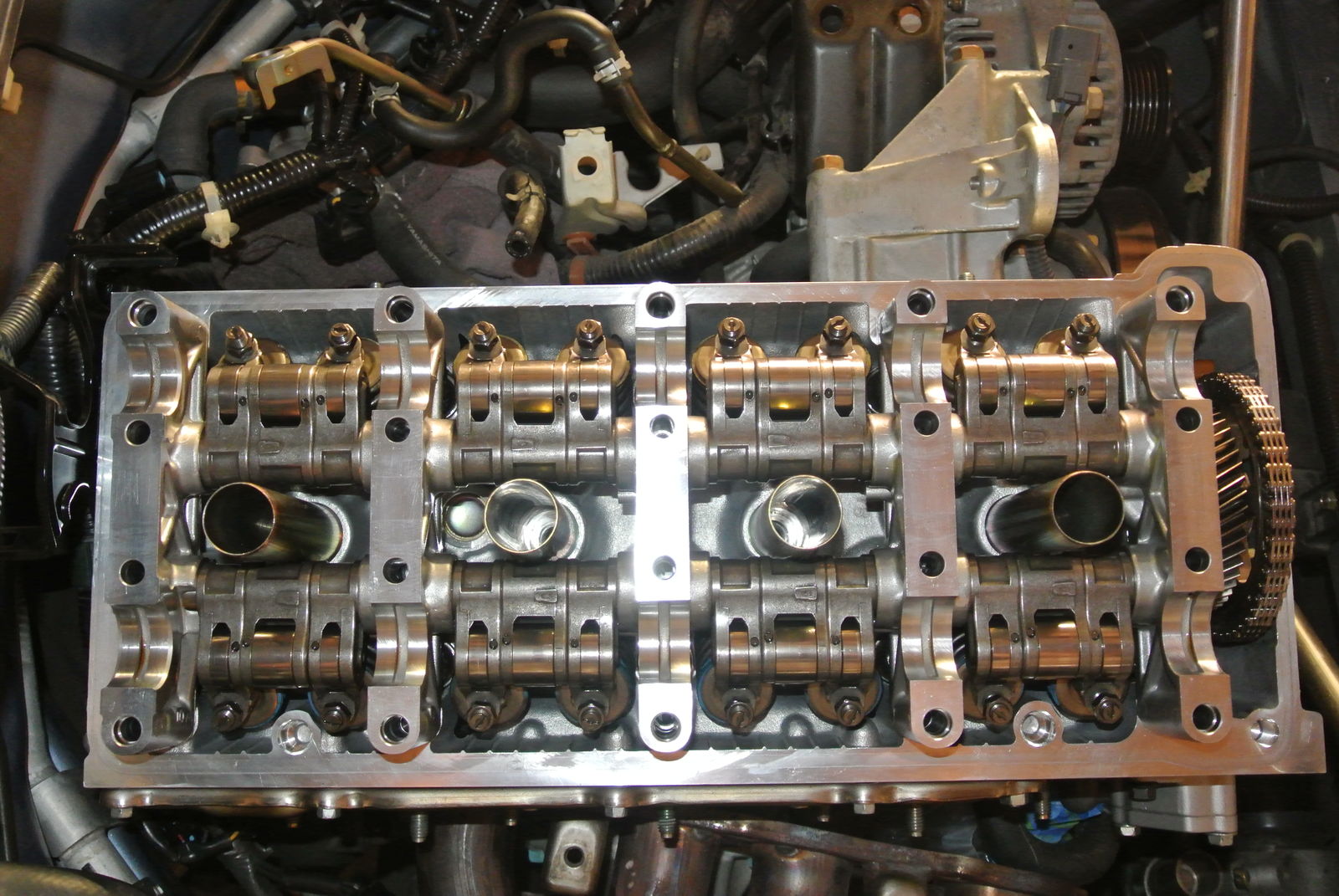

This past Saturday night I installed the rocker arm assembly, which was already cleaned and bagged, so I just oiled up the rocker pistons:

Gave the cam bearing journals another cleaning, cleaned and assembly lubed the cams and installed them. I think my timing marks are pretty good, from when I first put them in, to when all the caps were torqued down.

Then on Sunday afternoon the moment of truth came when I set all of the valve clearances and turned the crank to each cyl. TDC....smooth as silk. Then I put the red top on and installed the spark plugs. I have to say setting the clearances with no intake or exhaust manifold on the head is a big convenience. Hopefully a convenience I'll never get to experience again!

Then I put the red top on and installed the spark plugs. I have to say setting the clearances with no intake or exhaust manifold on the head is a big convenience. Hopefully a convenience I'll never get to experience again!

Next up the header, but I have to drive up to Medford tomorrow to pick up new nuts, which I somehow overlooked when ordering all my parts from Majestic.

Gave the cam bearing journals another cleaning, cleaned and assembly lubed the cams and installed them. I think my timing marks are pretty good, from when I first put them in, to when all the caps were torqued down.

Then on Sunday afternoon the moment of truth came when I set all of the valve clearances and turned the crank to each cyl. TDC....smooth as silk.

Next up the header, but I have to drive up to Medford tomorrow to pick up new nuts, which I somehow overlooked when ordering all my parts from Majestic.

#15

.006"!!! these people like to live dangerously. The mill limit is .008", and the service limit for head warpage is .002", so they left you with just enough margin that it should be reliable. Those .006" will bump up your compression ratio from 11:1 to ~11.8:1, which is fine, I just hope you have 93 octane in your area.

#16

Thread Starter

Jesus, slowcrash! I had a panic attack when I read your post this morning! Shop owner told me I would be fine, stock head gasket would be fine. Of course I'm in California, best pump gas we have is 91. Should I start using octane booster? I would have used a thicker head gasket than stock if I had realized the compression ratio would be raised that much, you can see how far I've come in putting everything back together

#19

Should be fine, stock ecu is good for up to 12.5:1 according to a Honda engineer I know. JDM compression ratio is that high.

#20

11.7:1