Ohlins DFV's - Review

#21

I can confirm that stock DFV fronts do have hysteresis at the stiffest settings. I don't know about the stock rears (didn't get mine dynoed prior to the valve). Pretty sure my re-valved rears don't have any hysteresis.

#22

Every shock will exhibit some hysteresis. From the testing I've done, hysteresis appears to be a function of how much the shims are being exercised. This, in turn, is a function of piston velocity, shim stack design and adjustment settings. For the Ohlins TTX25 design, seal friction doesn't appear to play a part in the hysteresis. Only the adjuster settings and the piston velocity. At full soft, I did not see any notable hysteresis, which would imply the seal drag has a minimal effect.

EDIT: the plots below are from an Ohlins TTX25 damper (really a Cane Creek damper), not a S2k Ohlins DFV

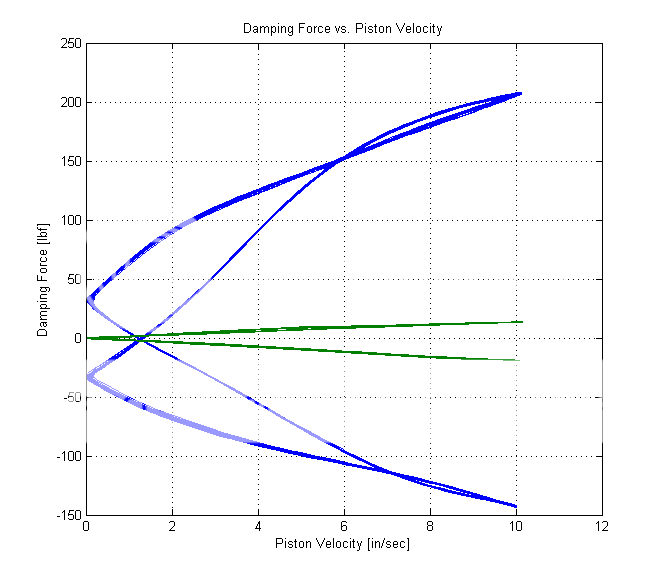

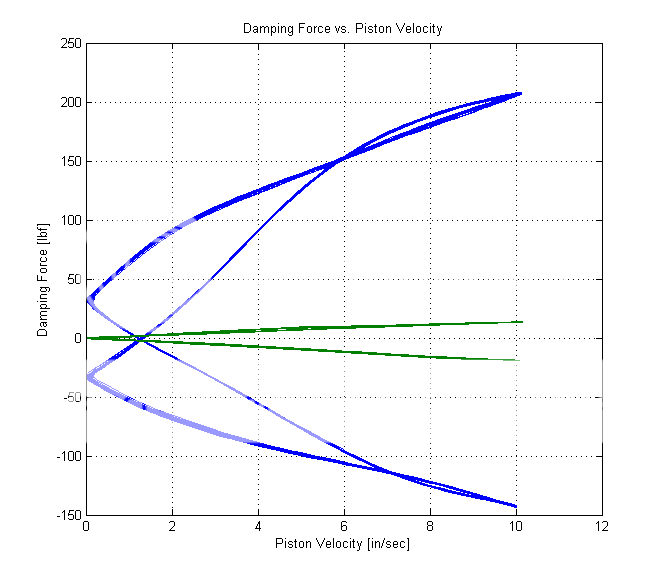

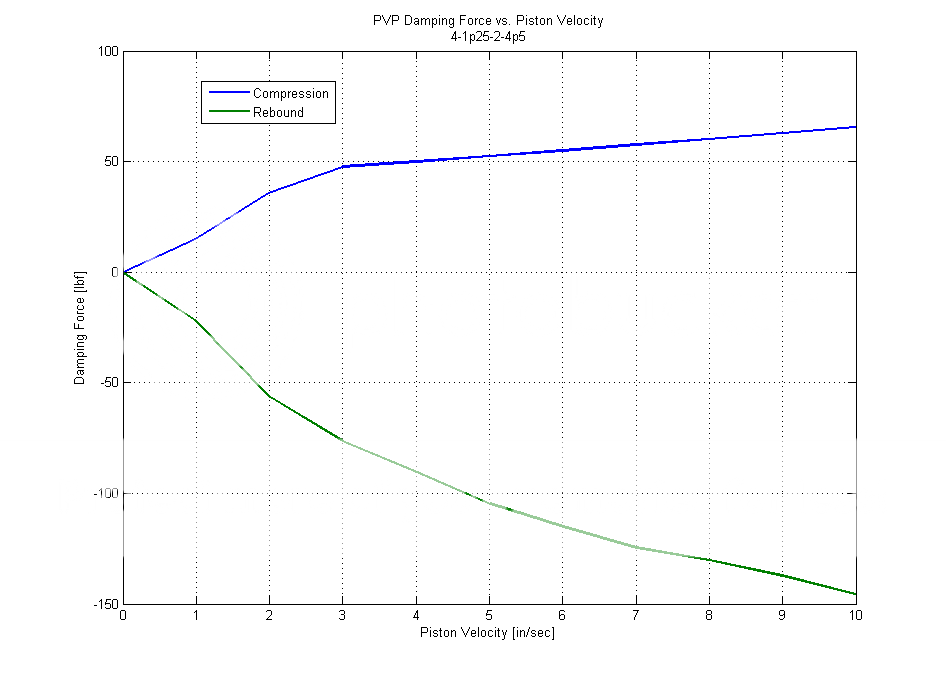

Here's the range of adjustment. Blue is every adjuster (4-way adjustable) at full stiff. Green is every adjuster at full soft. You can see the green damper curve doesn't show any hysteresis while the blue curve exhibits notable hysteresis below 6 in/sec.

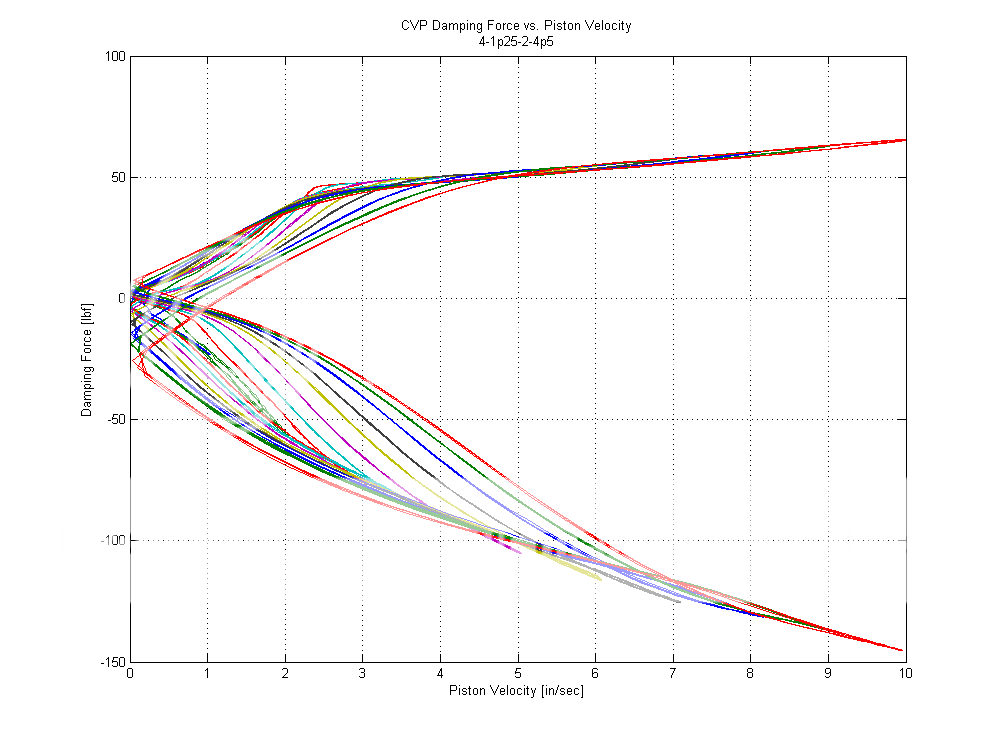

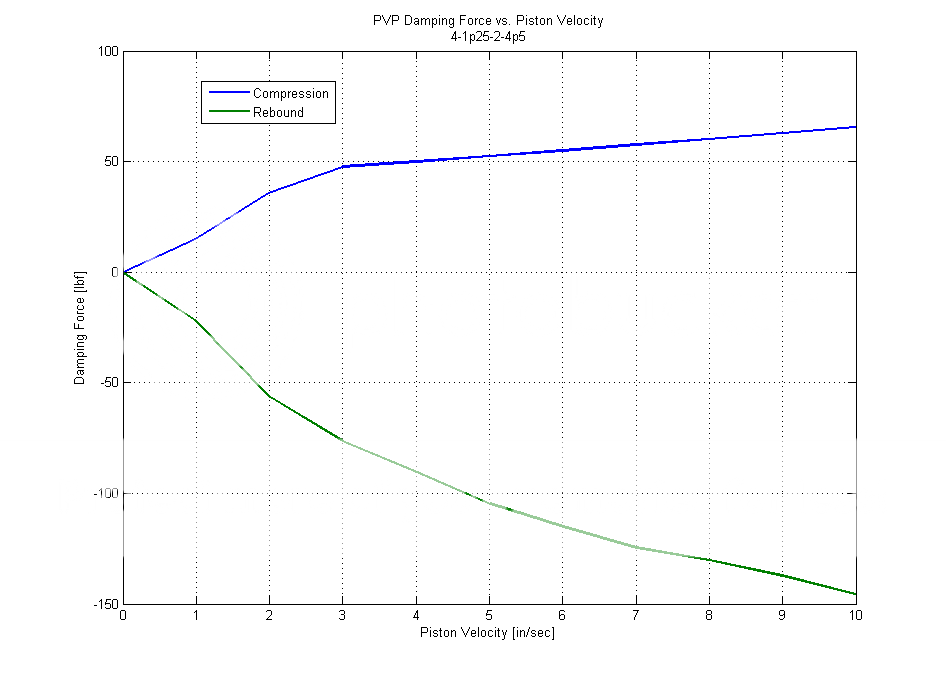

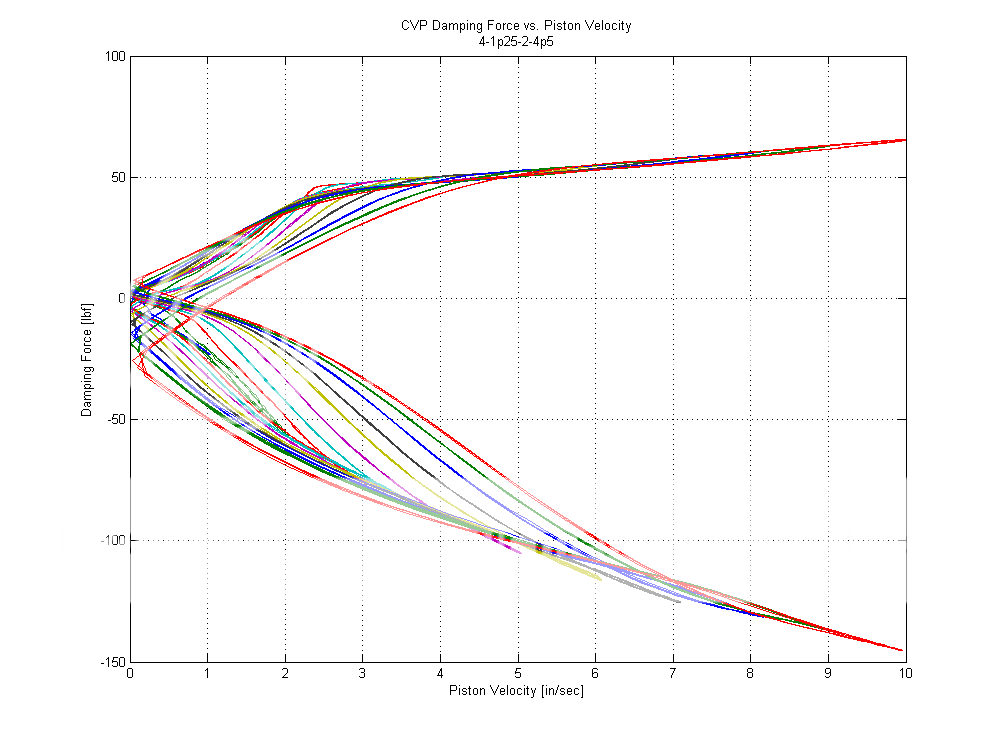

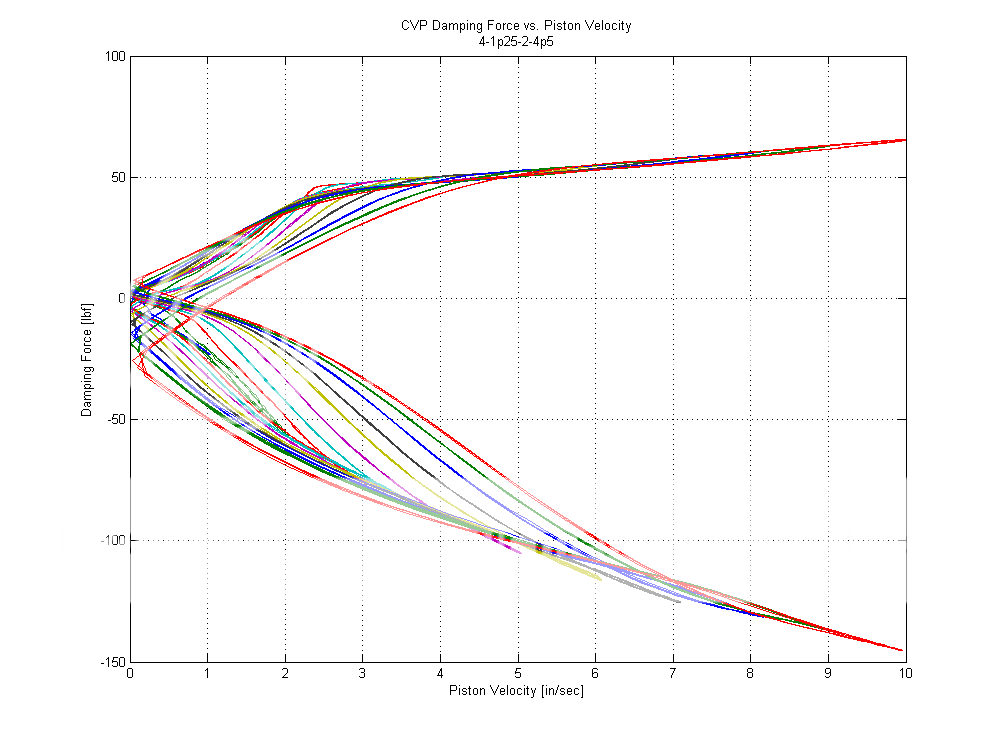

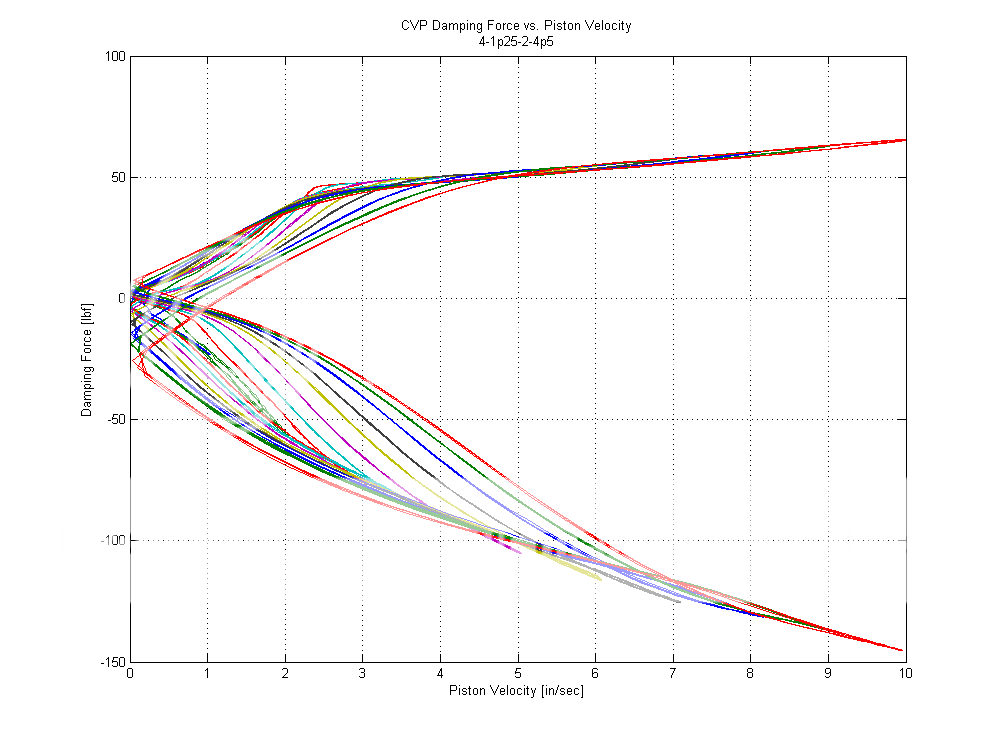

Here's the same damper at a given setting, overlaying CVPs for 0-1 in/sec, 0-2 in/sec, etc.... all the way up to 10 in/sec. You can see that the hysteresis is lowest (I know it's tough to see in there) for the 0-1 in/sec curve. The 0-10 in/sec curve exhibits the most hysteresis.

FYI, the overlay of the 10 incrementing velocity curves is how you manually generate a PVP.

EDIT: the plots below are from an Ohlins TTX25 damper (really a Cane Creek damper), not a S2k Ohlins DFV

Here's the range of adjustment. Blue is every adjuster (4-way adjustable) at full stiff. Green is every adjuster at full soft. You can see the green damper curve doesn't show any hysteresis while the blue curve exhibits notable hysteresis below 6 in/sec.

Here's the same damper at a given setting, overlaying CVPs for 0-1 in/sec, 0-2 in/sec, etc.... all the way up to 10 in/sec. You can see that the hysteresis is lowest (I know it's tough to see in there) for the 0-1 in/sec curve. The 0-10 in/sec curve exhibits the most hysteresis.

FYI, the overlay of the 10 incrementing velocity curves is how you manually generate a PVP.

#23

Here's the same damper at a given setting, overlaying CVPs for 0-1 in/sec, 0-2 in/sec, etc.... all the way up to 10 in/sec. You can see that the hysteresis is lowest (I know it's tough to see in there) for the 0-1 in/sec curve. The 0-10 in/sec curve exhibits the most hysteresis.

#24

So is it correct to interpret that at this setting, hysteresis is the least when the piston is changing direction from having been moving at a slower speed? As in, there is some residual effect from super high-speed movements that tends to induce hysteresis on the return movement?

#25

Originally Posted by thomsbrain' timestamp='1418079178' post='23430979

So is it correct to interpret that at this setting, hysteresis is the least when the piston is changing direction from having been moving at a slower speed? As in, there is some residual effect from super high-speed movements that tends to induce hysteresis on the return movement?

#26

EDIT: sorry to derail your review thread, Terrible01.

#27

Originally Posted by thomsbrain' timestamp='1418083796' post='23431045

That makes sense. I think where I was confused was that there was less hysteresis at a given piston speed if the overall dyno sweep was slower. So 1 in/sec on a 0-1 sweep seemed to have less hysteresis than 1 in/sec on a 0-10 sweep. Or am I reading the graph wrong?

EDIT: sorry to derail your review thread, Terrible01.

It's still on topic in my eyes. I'm even learning a bit here. lol

#28

So given the dyno plots that are shown, I'm asking the more knowledgeable guys what you think the max spring rate is that could be run on these with off the shelf valving. For the all purpose use that I'm after I don't see the need to have them revalved and was looking most towards a 650/550lb setup or 12/10k setup.

I recently ran mine on the off the shelf rates at an autocross and found 2 from stiff up front and 6-7 from stiff out back worked very well for me. I haven't tried running them at full stiff but also haven't felt like they needed it. I was running the fronts a little stiffer to make up for the lack of massive front sway. If I had a little more bar I'd likely run them a tad softer.

I recently ran mine on the off the shelf rates at an autocross and found 2 from stiff up front and 6-7 from stiff out back worked very well for me. I haven't tried running them at full stiff but also haven't felt like they needed it. I was running the fronts a little stiffer to make up for the lack of massive front sway. If I had a little more bar I'd likely run them a tad softer.

#29

[attachment=70482::] DFV makes an average of 325 lbs of rebound damping force at 2"/sec on full stiff

If you look at the national competitor's rear penske's 8300 dyne plot, controlling 750lb springs, middle setting is 180 lbs at the same speed. Softest is 60 lbs and stiffest is 300. I've attached the pic but again, it is failing to show (on desktop anyway)

[attachment=70483::]

If you look at the national competitor's rear penske's 8300 dyne plot, controlling 750lb springs, middle setting is 180 lbs at the same speed. Softest is 60 lbs and stiffest is 300. I've attached the pic but again, it is failing to show (on desktop anyway)

[attachment=70483::]

#30

So given the dyno plots that are shown, I'm asking the more knowledgeable guys what you think the max spring rate is that could be run on these with off the shelf valving. For the all purpose use that I'm after I don't see the need to have them revalved and was looking most towards a 650/550lb setup or 12/10k setup.

I recently ran mine on the off the shelf rates at an autocross and found 2 from stiff up front and 6-7 from stiff out back worked very well for me. I haven't tried running them at full stiff but also haven't felt like they needed it. I was running the fronts a little stiffer to make up for the lack of massive front sway. If I had a little more bar I'd likely run them a tad softer.

I recently ran mine on the off the shelf rates at an autocross and found 2 from stiff up front and 6-7 from stiff out back worked very well for me. I haven't tried running them at full stiff but also haven't felt like they needed it. I was running the fronts a little stiffer to make up for the lack of massive front sway. If I had a little more bar I'd likely run them a tad softer.

I would like to know this as well