Earl's Fittings - Leaking oil

#21

Originally Posted by SgtB,May 12 2008, 10:34 AM

You never ever use teflon tape with earls. It's a conical face seal. If anything, including a tiny piece of teflon, gets in between the two faces it will leak.

Kix: you may be able to unscrew the fitting and trim a small piece off. The diy kits use the same fittings. I find the greddy kit puts a lot of pressure on the lines(the worst part of the install imho). That may be why they're failing. This is the second one I've heard of failing.

Kix: you may be able to unscrew the fitting and trim a small piece off. The diy kits use the same fittings. I find the greddy kit puts a lot of pressure on the lines(the worst part of the install imho). That may be why they're failing. This is the second one I've heard of failing.

As for the oil lines, it's very important to have them installed and clocked correctly. I had to loosen and re-angle the fittings to get it just right, so the oil lines do not touch any part of the chassis. If this is done correctly, there should be no added stress to the fittings or lines.

#22

Originally Posted by kix,May 11 2008, 07:21 PM

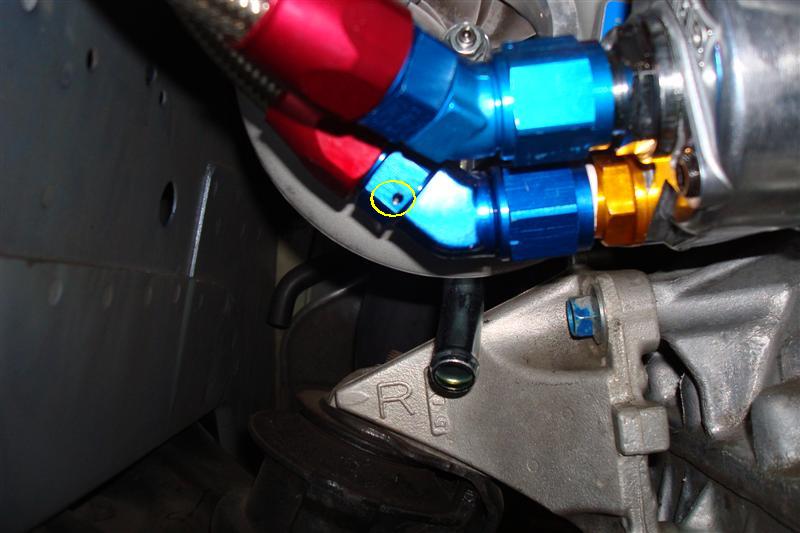

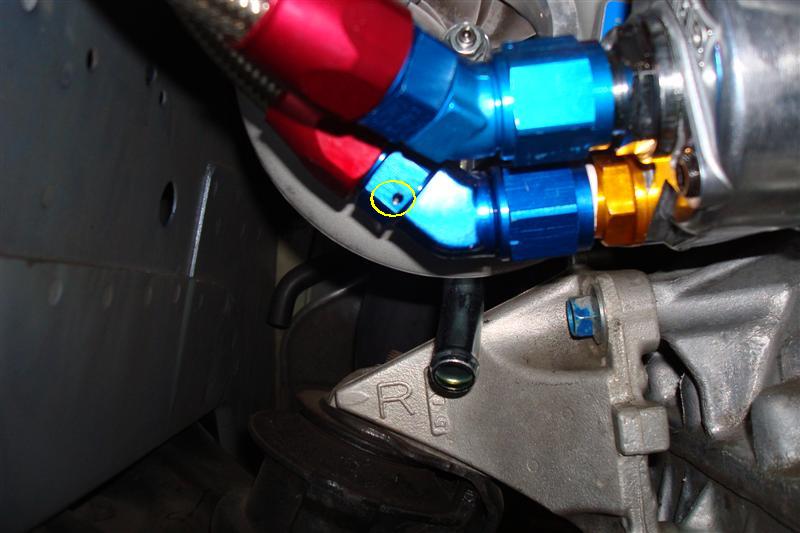

Ah,sorry for my laziness... macs dont have MSPAINT... here's where the leak is occuring.

I wouldn't think that you'd have a noticeable drop in pressure though, so you can probably ride your car. Just make sure the oil level remains full if you're travelling a longer distance. Driving around will create a mess under the hood...

BTW, a swivel fitting at that location is a good idea.

#24

What oil pressure sensor are you using? I was under the impression that the stock sensor was just an "on/off" switch that went off whenever pressure dipped below a certain point... Where did you install it?

I am probably going to be wanting oil pressure in the near future as well...

Thanks

John

I am probably going to be wanting oil pressure in the near future as well...

Thanks

John

#26

Registered User

Thread Starter

Join Date: Apr 2007

Location: Irvine/Orange

Posts: 1,174

Likes: 0

Received 0 Likes

on

0 Posts

Well I got back from the Earl's store near torrance. That place is like FITTINGS HEAVEN! I spoke to the guy there and he was very helpful. He said the most common failurs of his fittings are from people overtightening them which I know I did not.

Using the fittings I bought I showed him where the leak was occuring. He said it makes sense that oil/fluid would come out there ONLY if that line was under REAL high stress. As I mentioned before, he confirmed that the anti-seepage sealing system is what failed.

Anywho, I decided to by 4 fittings and a few feet of hose. I'm thinking the supplied hoses are a bit too short and perhaps the engine rocking back and forward during shifts is putting strain on the parts.

Oh, and I confirmed that the fittings do NOT need teflon tape. Only a bit of grease to help screw the fittings on the male AN adapters

Using the fittings I bought I showed him where the leak was occuring. He said it makes sense that oil/fluid would come out there ONLY if that line was under REAL high stress. As I mentioned before, he confirmed that the anti-seepage sealing system is what failed.

Anywho, I decided to by 4 fittings and a few feet of hose. I'm thinking the supplied hoses are a bit too short and perhaps the engine rocking back and forward during shifts is putting strain on the parts.

Oh, and I confirmed that the fittings do NOT need teflon tape. Only a bit of grease to help screw the fittings on the male AN adapters

#28

Registered User

Thread Starter

Join Date: Apr 2007

Location: Irvine/Orange

Posts: 1,174

Likes: 0

Received 0 Likes

on

0 Posts

http://www.anplumbing.com/

The site looks shady but I assure you they are 100% legit and you can walk into their showroom to buy on the spot

The site looks shady but I assure you they are 100% legit and you can walk into their showroom to buy on the spot

#29

Originally Posted by gotswap,May 12 2008, 12:52 PM

those look like -10 lines

Thread

Thread Starter

Forum

Replies

Last Post