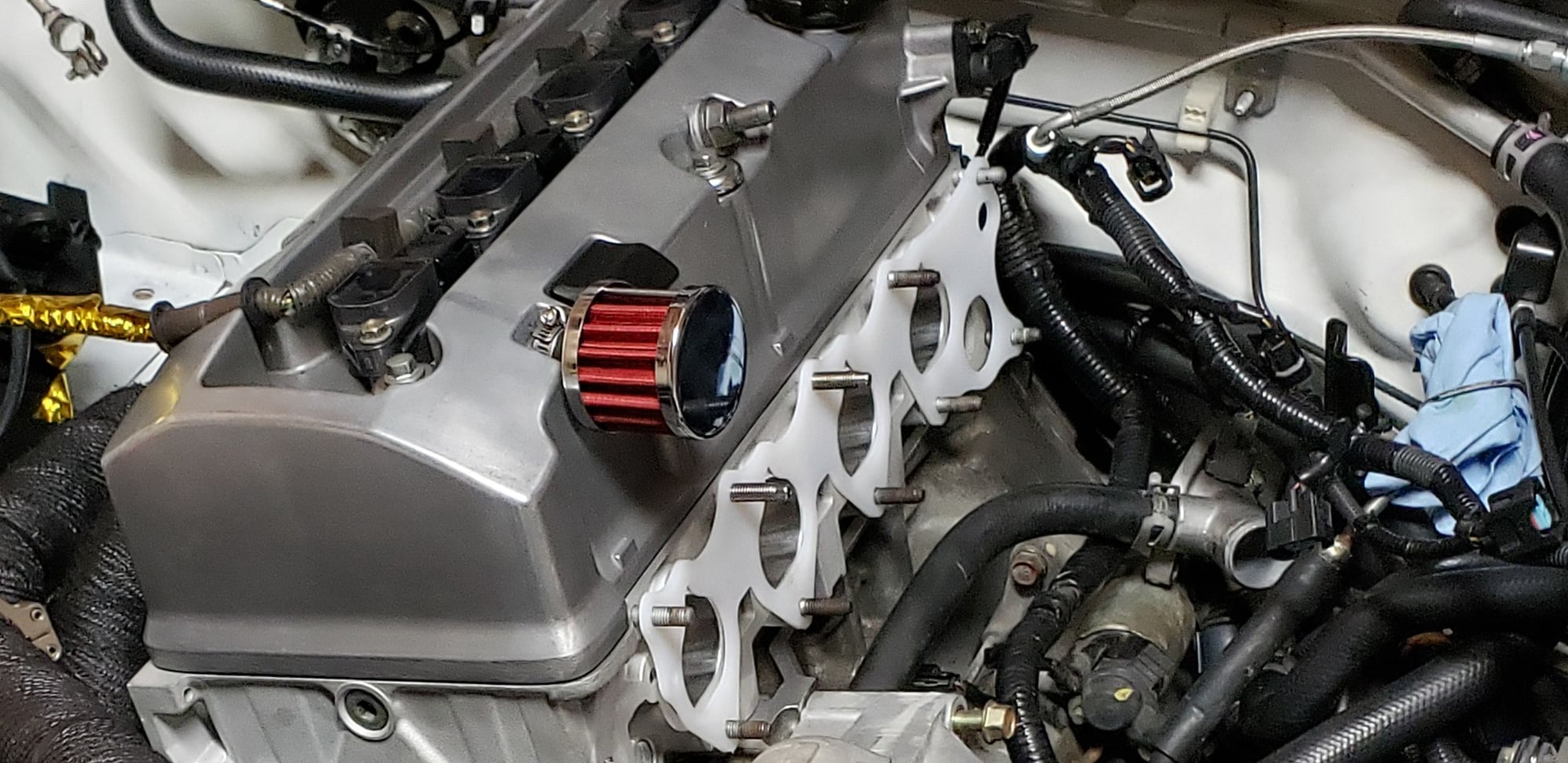

Hondata Intake manifold gasket

#1

So I had to remove my intake manifold looking for a piece of the AEM FPR I dropped into the engine bay. Fortunately I found it so since I had the manifold off I decided to order the Honda manifold gasket. Although S/Cs don't suffer as much as turbos from heat soak it would still be a good idea to keep the air as cool as possible before going into the engine. From what I read on this post, it looks like it's pretty effective. I don't have any baseline numbers to compare dyno numbers, nor will I remove it to see the difference but I figure I'd upgrade since the part was off.

#2

Ive heard that they melt on our motors and the bolts get loose. Not sure if you can maybe run an oem gasket directly on the head followed by the hondata gasket to help with the melting issue and use nylon nuts on the studs.

#4

Eight years, no issues. Torque, drive for a week, retorque.

HOWEVER........depending on the model year of your S, you will probably find a better effect from relocation air temp sensor than using the gasket. I have done both. Even with the gasket, the sensor heat soaks and is slow to respond to changes in intake air temp.

HOWEVER........depending on the model year of your S, you will probably find a better effect from relocation air temp sensor than using the gasket. I have done both. Even with the gasket, the sensor heat soaks and is slow to respond to changes in intake air temp.

#5

only issue I've had in 3 years with mine is that there is no hole for the coolant bleeder on the front of the block. Noticed this when I put my FBM manifold on, but that was an easy fix to just drill a hole through it.

#6

I was finally able to get everything put back together and everything seems fine. I had to grind the lower mount holes to account for the thicker gasket but the manifold as cool enough to touch after driving it around for 15 minutes. We'll see if it makes any difference on the dyno.

#7

Ive always used them and never had an issue. After using one for about 5 years and taking manifold off a couple times during that time frame it started to get pretty deformed in the areas exposed, but never leaked. This is what id expect. I think its worth doing if you already have the manifold off, but I think eliminating coolant circulation from the manifold entirely is more beneficial and in combination works great. Just cap off the supply line at the block port/thermostat which resides an arm length under the intake manifold. Much easier to see/get to with manifold off, but totally doable with it on if you know what your looking for. The easiest thing to do at that point is just cut the line and plug the end with a bolt and hose clamp and zip tie it to something so it inst dangling around.

Trending Topics

#8

Ive always used them and never had an issue. After using one for about 5 years and taking manifold off a couple times during that time frame it started to get pretty deformed in the areas exposed, but never leaked. This is what id expect. I think its worth doing if you already have the manifold off, but I think eliminating coolant circulation from the manifold entirely is more beneficial and in combination works great. Just cap off the supply line at the block port/thermostat which resides an arm length under the intake manifold. Much easier to see/get to with manifold off, but totally doable with it on if you know what your looking for. The easiest thing to do at that point is just cut the line and plug the end with a bolt and hose clamp and zip tie it to something so it inst dangling around.

#9

Originally Posted by s2000Junky' timestamp='1450767422' post='23834017

Ive always used them and never had an issue. After using one for about 5 years and taking manifold off a couple times during that time frame it started to get pretty deformed in the areas exposed, but never leaked. This is what id expect. I think its worth doing if you already have the manifold off, but I think eliminating coolant circulation from the manifold entirely is more beneficial and in combination works great. Just cap off the supply line at the block port/thermostat which resides an arm length under the intake manifold. Much easier to see/get to with manifold off, but totally doable with it on if you know what your looking for. The easiest thing to do at that point is just cut the line and plug the end with a bolt and hose clamp and zip tie it to something so it inst dangling around.

#10

The thermostat and temp sensor is not bypassed due to where its located. And also the IAC valve/sensor reads regardless if there is fluid passing through it or not. No issues, no faults triggered. Your only isolating the intake manifold and therefore TB of course, from coolant. Or better put, heat

im going to use a skunk2 intake manifold gasket will give my findings aswell: