How I rebuilt my Paxton Novi 1000

#1

Thread Starter

I promised a couple of members on the board that I would write a summary of how I built my Novi 1000.

This is not a HOW TO! it's simply some pictures and information on how I did mine so please be aware this may not be the correct procedure.

I thought mine sounded loud so I wanted to change the bearings, hence why I rebuilt it.

First I removed the supercharger from the mounting plate:

Removed the pulley and washer:

Then I removed all the allen key cap head bolts holding the rear casing on:

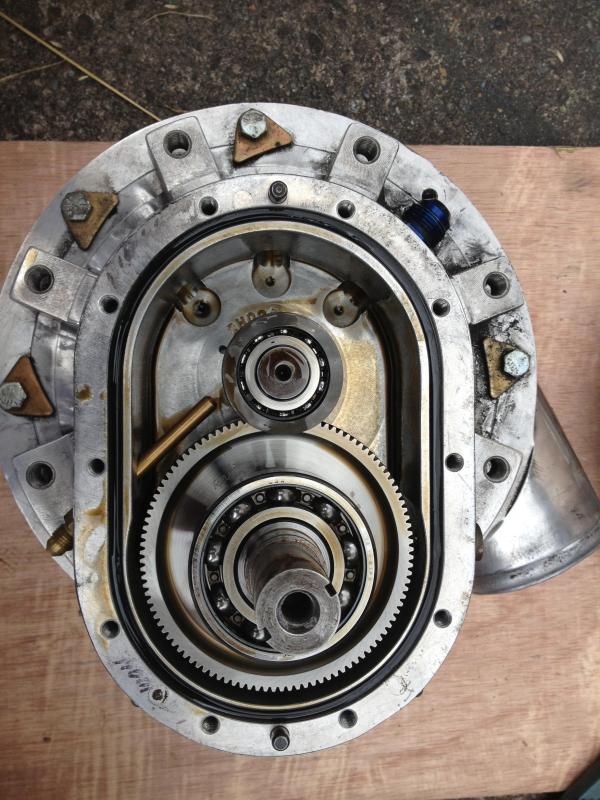

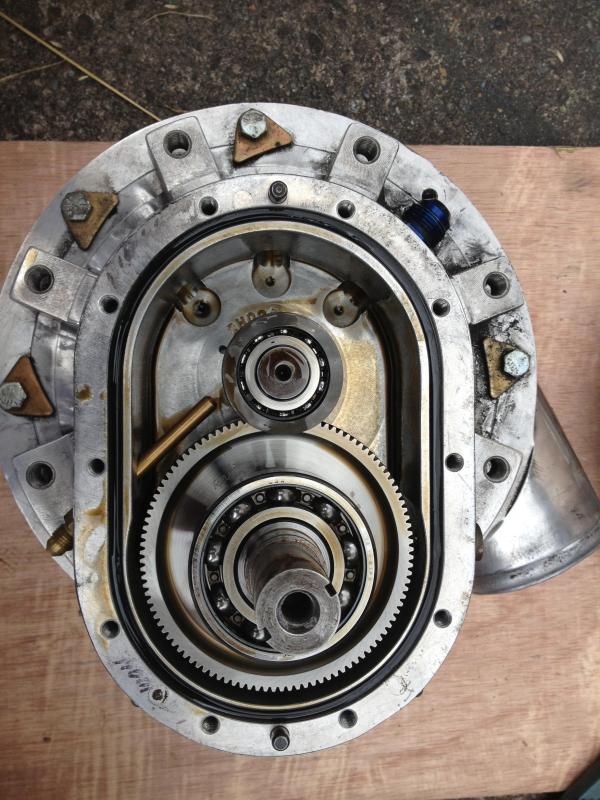

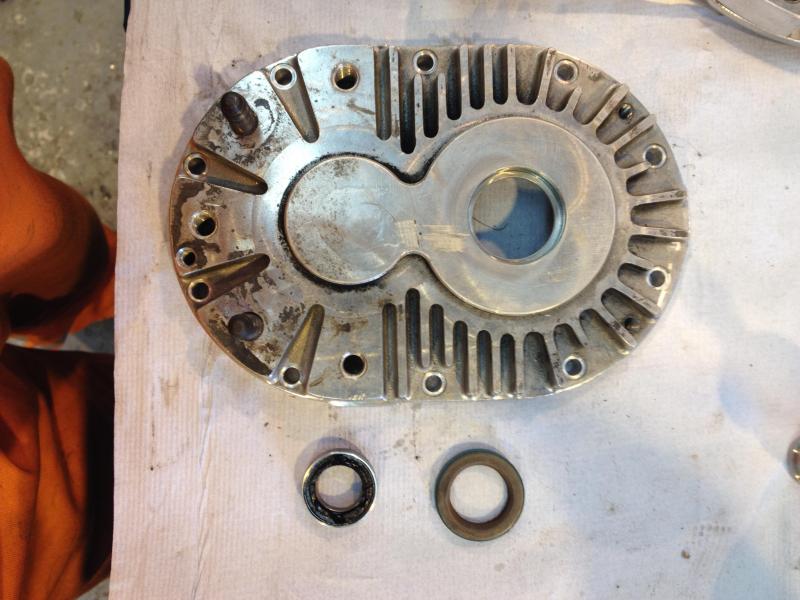

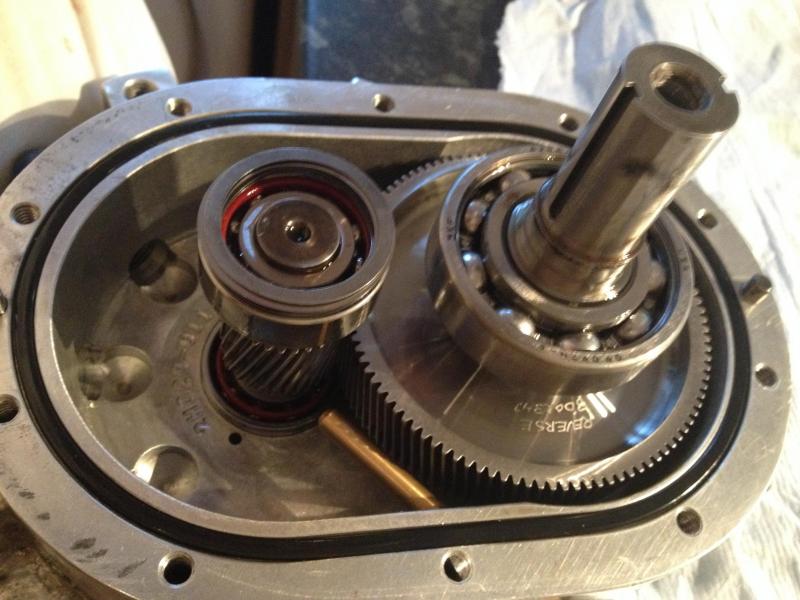

View of inside:

I removed the three spring washers and two spacing washers form the output shaft bearing. I placed these in the insert in the housing plate for safe keeping:

Output shaft bearings:

Input shaft bearings:

Then I lifted the input shaft assembly out:

Removed the spring washer and stored it for safe keeping:

I then flipped the casing over and removed the volute:

This is not a HOW TO! it's simply some pictures and information on how I did mine so please be aware this may not be the correct procedure.

I thought mine sounded loud so I wanted to change the bearings, hence why I rebuilt it.

First I removed the supercharger from the mounting plate:

Removed the pulley and washer:

Then I removed all the allen key cap head bolts holding the rear casing on:

View of inside:

I removed the three spring washers and two spacing washers form the output shaft bearing. I placed these in the insert in the housing plate for safe keeping:

Output shaft bearings:

Input shaft bearings:

Then I lifted the input shaft assembly out:

Removed the spring washer and stored it for safe keeping:

I then flipped the casing over and removed the volute:

#2

Thread Starter

Now off I went to my workshop (well my work's workshop:

Picture of parts:

I then placed the casing into a vice (with the output shaft/bearings still attached), heated the impeller with a blow torch then removed the locking nut and impeller. once you remove these the output shaft assembly just pops out:

I melted the old output shaft seal but this was getting replaced anyway:

Then put the washers with the impeller for safe keeping:

I then removed all bearings with bearing pullers

I removed all four bearings and refitted them using a bearing induction heater. If you haven't got a bearing induction heater just heat the bearings in some fresh motor oil to 100'C in an oven!:

WHEN ISTALLING THE NEW BEARINGS MAKE SURE YOU INSTALL THEM IN THE SAME ORINTATION AS REMOVED! NUMBERS FACING OUTWARDS!

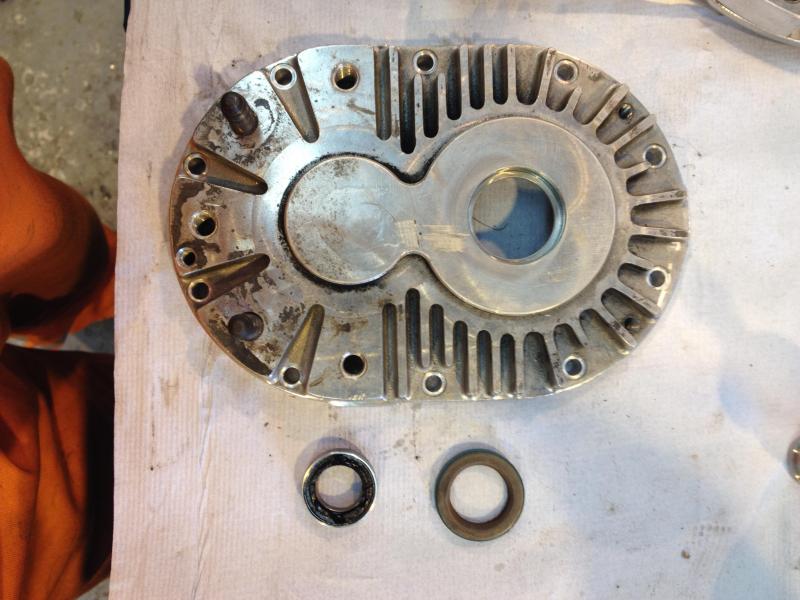

I then removed the input & output shaft seal with a press and hand tools:

I then pressed in the new seals - Please note; you can easily damage the seals so please be cautious!!! You need to heat the casing with a blow torch (or this is how Paxton recommend). You must press the output shaft in on the inner race/sleeve ONLY! I used some 17mm round bar for the output shaft. The input shaft can be done by hand

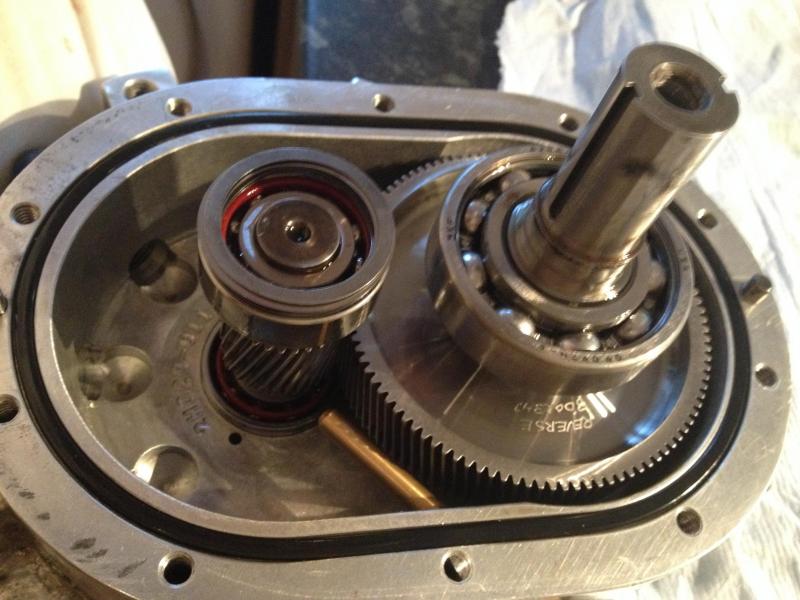

I then laid all the components out and re-assembled:

Once I'd reassembled all the parts within the casing. I installed the rear cover with the allen key bolts. Then placed the input shaft into a vice and clamped it. Heated the impeller with a blow torch and dropped the impeller back onto the output shaft.

Like this:

Then I screwed on the lock nut and tightend.

You can now re-install the impeller, volute and pulley.

I then fitted the charger to the car. I spun the input shaft by hand (with the belt removed), I could hear the impeller touching the volute so I clamped the input shaft with a pair of stilsons and tighten the impeller locking nut. I tightened it to what felt tight to me. Please go careful as you could break the helical gears if excessive force is applied!

I then marked the lock nut with a line to see if it moves - which it hasn't so far.

Picture of parts:

I then placed the casing into a vice (with the output shaft/bearings still attached), heated the impeller with a blow torch then removed the locking nut and impeller. once you remove these the output shaft assembly just pops out:

I melted the old output shaft seal but this was getting replaced anyway:

Then put the washers with the impeller for safe keeping:

I then removed all bearings with bearing pullers

I removed all four bearings and refitted them using a bearing induction heater. If you haven't got a bearing induction heater just heat the bearings in some fresh motor oil to 100'C in an oven!:

WHEN ISTALLING THE NEW BEARINGS MAKE SURE YOU INSTALL THEM IN THE SAME ORINTATION AS REMOVED! NUMBERS FACING OUTWARDS!

I then removed the input & output shaft seal with a press and hand tools:

I then pressed in the new seals - Please note; you can easily damage the seals so please be cautious!!! You need to heat the casing with a blow torch (or this is how Paxton recommend). You must press the output shaft in on the inner race/sleeve ONLY! I used some 17mm round bar for the output shaft. The input shaft can be done by hand

I then laid all the components out and re-assembled:

Once I'd reassembled all the parts within the casing. I installed the rear cover with the allen key bolts. Then placed the input shaft into a vice and clamped it. Heated the impeller with a blow torch and dropped the impeller back onto the output shaft.

Like this:

Then I screwed on the lock nut and tightend.

You can now re-install the impeller, volute and pulley.

I then fitted the charger to the car. I spun the input shaft by hand (with the belt removed), I could hear the impeller touching the volute so I clamped the input shaft with a pair of stilsons and tighten the impeller locking nut. I tightened it to what felt tight to me. Please go careful as you could break the helical gears if excessive force is applied!

I then marked the lock nut with a line to see if it moves - which it hasn't so far.

#3

Thread Starter

For information:

I bought the bearings from a UK supplier no problem, they cost my £150

Parts I used:

X2 SKF 6206 C3 bearings

X2 Barden 203H bearings

X1 input shaft seal

X1 output shaft seal - 30mm

Seals can be bought from here:

http://www.superchargerrebuild.com/paxton/

I did purchase a seal from JBO but I didn't like the type of output shaft seal so opted for the OEM type from the above.

Any questions please ask, I typed that lot as quickly as possible

I bought the bearings from a UK supplier no problem, they cost my £150

Parts I used:

X2 SKF 6206 C3 bearings

X2 Barden 203H bearings

X1 input shaft seal

X1 output shaft seal - 30mm

Seals can be bought from here:

http://www.superchargerrebuild.com/paxton/

I did purchase a seal from JBO but I didn't like the type of output shaft seal so opted for the OEM type from the above.

Any questions please ask, I typed that lot as quickly as possible

#7

Great information! I recently rebuilt my Paxton 1000 as well and my impeller only had one shim on it, compared to two on yours! Seems that there is quite a bit of variation with their builds. Also, from my research, the impeller nut needed 35 ft/lbs, or at least, that's what a paxton manual said. Thanks for the write up!

Trending Topics

#9

Nice write up.

As long as you dont over spin the blowers rated speed, or over tighten the pulley belt, ive seen 150k+ miles on these units before a rebuild was needed. They all sound like a coffee grinder at idle.

As long as you dont over spin the blowers rated speed, or over tighten the pulley belt, ive seen 150k+ miles on these units before a rebuild was needed. They all sound like a coffee grinder at idle.