Cylinder #2 rod bearing failure again :-(

#12

Moderator

By “beyond”, I am referring to not only finish, but flatness, trueness, roundness. If the shop made any determinations or repairs that were deemed “close enough”, the bearing life will be short. These “close enough” situations can work in other engines, but always fail with the S2000.

#13

By “beyond”, I am referring to not only finish, but flatness, trueness, roundness. If the shop made any determinations or repairs that were deemed “close enough”, the bearing life will be short. These “close enough” situations can work in other engines, but always fail with the S2000.

Thanks!

#14

Maybe the only thing for these cranks is micro polishing in the <correct rotation>

#16

^^^ Good find

#17

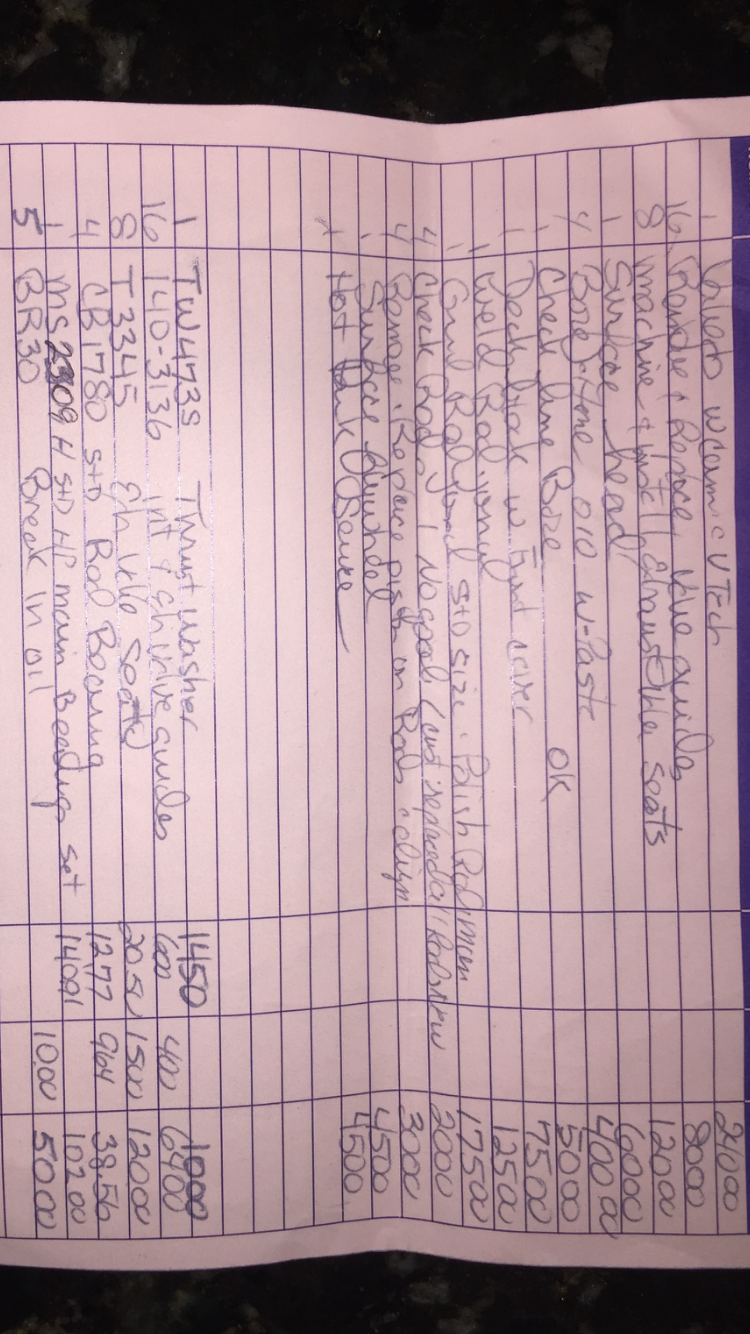

I called the machine shop who sent my crank out to be worked on. Per the machine shop, my crank had a "nitride weld", then grind and polish to #2 journal. I shopped locally for a used crank yesterday and all of the recyclers don't separate the crank from the motor. So I'd need to buy a motor. No luck finding a new crank either. The machine shop who did my work, also does work for many of the Sacramento franchised dealerships. They stand by their work and well as who they sub'd the crank out to. I going to approach this issue as though we have the incorrect bearing size for #2 journal (the one that was worked on). I called a local Honda dealer and was told there are 7 sizes of rod bearings, going by color code. I'm not sure what bearing to start with and plasti-gauge to. I'm thinking start something smaller (undersized.....not sure if that exists) and go from there. Dealer was $36 for both halves, so I don't want to buy all 7 sizes. Anyone have a suggestion on how to approach this? Do we need to measure the journal with a micrometer and compare? I'm not a tech, just want to be fairly systematic and how we approach the issue. My preference is to keep the crank in the motor and not tear down. To restate an earlier post, we inspected journals 1,3 and 4......all surfaces looked great. I'm guessing here, but would damage more likely to occur on a bearing that was too tight of a fit or too loose? I'm thinking too tight, but I don't know. All con rod bearings installed on the rebuild were the same spec, from the same batch.

#18

I'd mic'ed the bearing surfaces, of your crank. See what are the variances. Go from there.

Good luck!

Good luck!

#19

I called the machine shop who sent my crank out to be worked on. Per the machine shop, my crank had a "nitride weld", then grind and polish to #2 journal. I shopped locally for a used crank yesterday and all of the recyclers don't separate the crank from the motor. So I'd need to buy a motor. No luck finding a new crank either. The machine shop who did my work, also does work for many of the Sacramento franchised dealerships. They stand by their work and well as who they sub'd the crank out to. I going to approach this issue as though we have the incorrect bearing size for #2 journal (the one that was worked on). I called a local Honda dealer and was told there are 7 sizes of rod bearings, going by color code. I'm not sure what bearing to start with and plasti-gauge to. I'm thinking start something smaller (undersized.....not sure if that exists) and go from there. Dealer was $36 for both halves, so I don't want to buy all 7 sizes. Anyone have a suggestion on how to approach this? Do we need to measure the journal with a micrometer and compare? I'm not a tech, just want to be fairly systematic and how we approach the issue. My preference is to keep the crank in the motor and not tear down. To restate an earlier post, we inspected journals 1,3 and 4......all surfaces looked great. I'm guessing here, but would damage more likely to occur on a bearing that was too tight of a fit or too loose? I'm thinking too tight, but I don't know. All con rod bearings installed on the rebuild were the same spec, from the same batch.

#20