F20C bearings

#21

Registered User

Thread Starter

sorry for your headache, my mechanic told me to order the same bearings, that's why all my questions as nobody could tell what PNs to order, but when Billman said that mines are not OEM, now things become more clearer.

I will use Plastigace, I don't think I can use the mic as the engine is still on the car.

So going further...should I order for the mains bearings only 3 sets of Brown, Green and Yellow to check for clearances ?

Can you combine the colors in the set, like 1 bearing green top and 1 brown bottom, or it must be the same color per set ?

What other parts should I change ? Maybe the oil pump as I have one, but I believe I have the old model, the rotor has 4 bumps, the upgraded one has 6 but I'm not really sure.

I will use Plastigace, I don't think I can use the mic as the engine is still on the car.

So going further...should I order for the mains bearings only 3 sets of Brown, Green and Yellow to check for clearances ?

Can you combine the colors in the set, like 1 bearing green top and 1 brown bottom, or it must be the same color per set ?

What other parts should I change ? Maybe the oil pump as I have one, but I believe I have the old model, the rotor has 4 bumps, the upgraded one has 6 but I'm not really sure.

#22

Updated oil jets? Depending on how apart your motor is, ap2 valve retainers while you're in there. Not sure how necessary it is, but when I had my motor rebuilt, they polished the crank, checked the rods, pistons, and head and cleaned everything while checking for microcracks. Ended up replacing conrods cause they were out of spec, having the cylinders honed, and new oil pump installed. I have heard the whole motor should be cleaned to make sure that all metal bits from the bearing are taken out, but I'm not an expert. Perhaps Billman can chime in on that.

#23

If ur replacing mains the crank will most deffly come out.

plasti gauge is a good tool; IN the right hands. But mic'ing can also be as well just at as damaging if u don't know what ur doing.

U cannot look at a crank an say it's fine. If the bearings r not OEM then that even further shows u cannot just throw something together n hope for the best. GL! Listen to these guys, do it right the first time. Drop the crank take it to get mic'd if u have to, have the main bores and con rods bore gauged and go from there. U want instant gratification with all the answers but this isn't how it works.

Even with the codes on the block and a "crank that looks fine" no one is gonna answer you cuz anyone with sense knows better to go on a whim like that n slap it together.

plasti gauge is a good tool; IN the right hands. But mic'ing can also be as well just at as damaging if u don't know what ur doing.

U cannot look at a crank an say it's fine. If the bearings r not OEM then that even further shows u cannot just throw something together n hope for the best. GL! Listen to these guys, do it right the first time. Drop the crank take it to get mic'd if u have to, have the main bores and con rods bore gauged and go from there. U want instant gratification with all the answers but this isn't how it works.

Even with the codes on the block and a "crank that looks fine" no one is gonna answer you cuz anyone with sense knows better to go on a whim like that n slap it together.

Last edited by MorngWoodStewie; 02-06-2017 at 04:45 PM.

The following users liked this post:

doggz (02-06-2017)

#24

I'd learn to use plasti-gauge. Great tool for checking rod and crank tolerances. Figure out which bearing set you need, after you get the tolerance readings from plasti-gauge.

#26

#27

Moderator

If you spun a rod bearing, the next bearing you install is guaranteed to fail in a week or two if the crank is not carefully hand polished.

Only 15-25% of crankshafts are saveable by in-car polishing.

Highly recommend getting the manual, or at least a copy of the needed pages.

Only 15-25% of crankshafts are saveable by in-car polishing.

Highly recommend getting the manual, or at least a copy of the needed pages.

#28

Registered User

Thread Starter

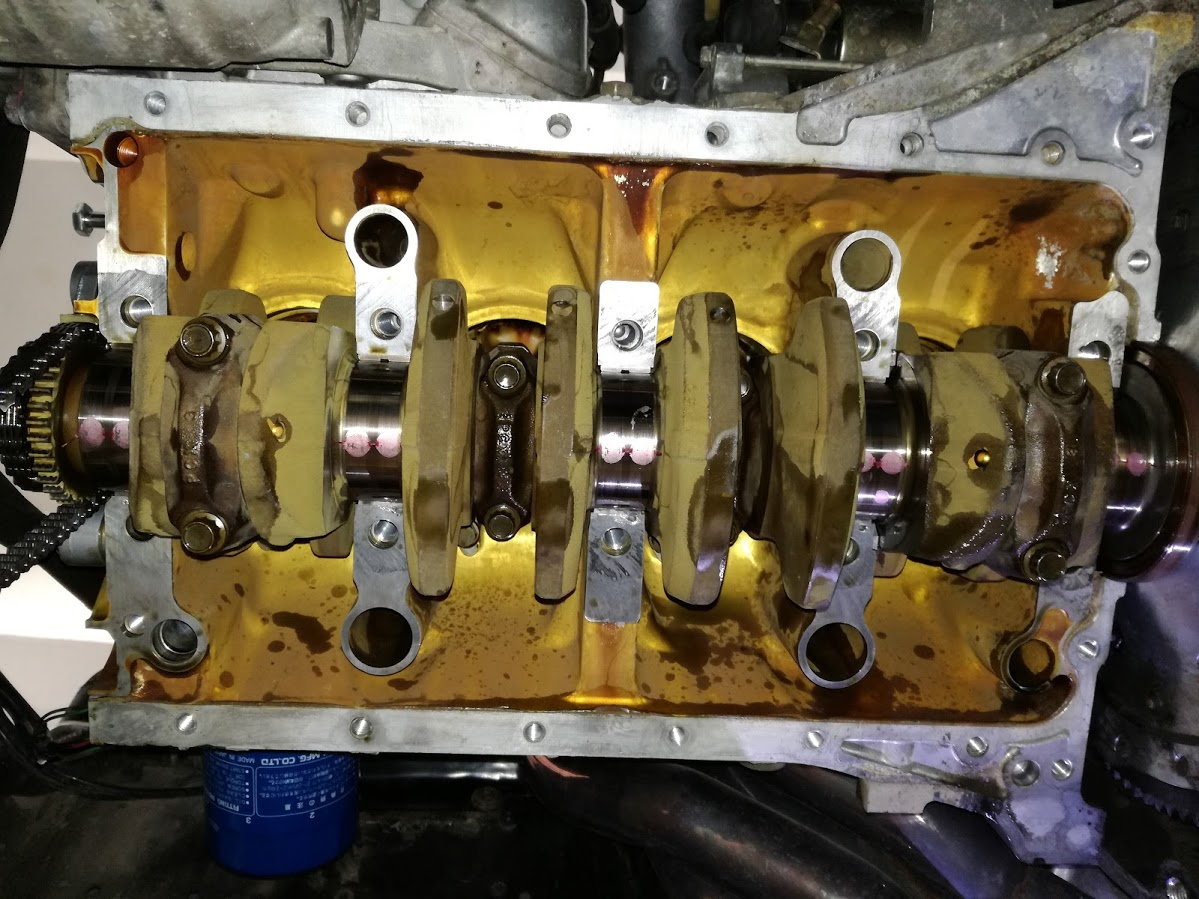

So in the end, I replace all the bearings with the exact ones that I had previously (they were the original ones, all OEM), plastigauge all in spec: mains are 0.025 and 0.030 mm, running hard for 1 month now and no issues. I didn't do any crank polishing as it wasn't necesary.

The presure is way better now: warm engine at idle 12-18 psi and at 3000 rpm 90-100 rpm.

I'm a little bit worried, in the manual should be 85 psi at 3000 rpm, not really sure if it's good or bad too much presure, I'm running 5-40w Motul Excess 8100 with new oil pump and upgraded oil banjo bolts.

Below some photos with the plastigauge with the motor on the car.

The presure is way better now: warm engine at idle 12-18 psi and at 3000 rpm 90-100 rpm.

I'm a little bit worried, in the manual should be 85 psi at 3000 rpm, not really sure if it's good or bad too much presure, I'm running 5-40w Motul Excess 8100 with new oil pump and upgraded oil banjo bolts.

Below some photos with the plastigauge with the motor on the car.

Last edited by doggz; 04-12-2017 at 04:50 AM.

#30