Repairable? Oil Pressure Sender

#1

Thread Starter

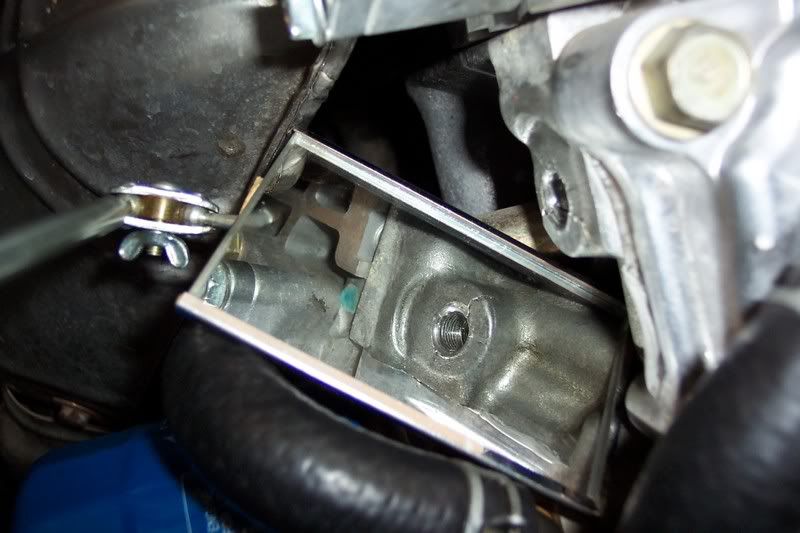

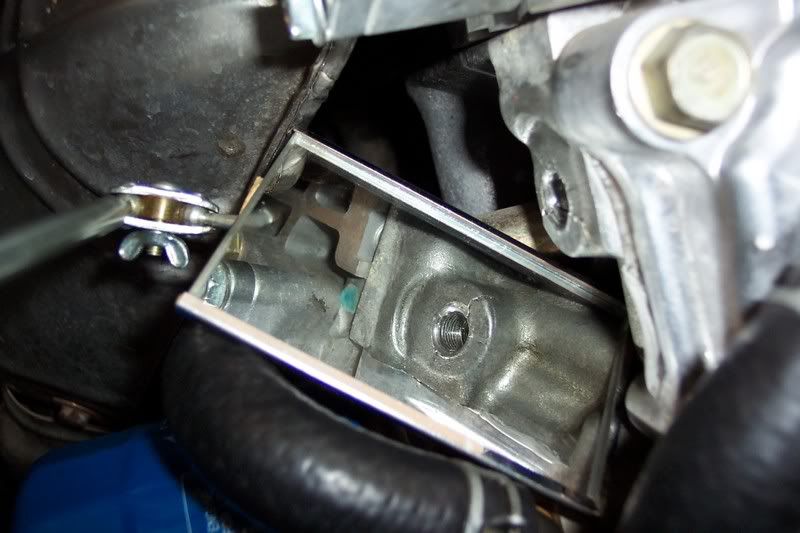

Well, I'm not the first one to have this happen, but I figured I'd make another thread about this to warn people about tapered fittings in this hole...our block is only aluminum and it WILL crack.

I'm not sure if this will be fixable without pulling the motor out of the car. And IMO if the motor needs to be pulled, the bottom end will simply be replaced with a "built" 2.2L, basically I'd just look into Pauter rods and some upgraded pins for the F22 short block.

If this can be fixed without pulling the motor, that would be even better, but I am planning for the worst and hoping for the best.

here is a link to one other thread of the same occurance https://www.s2ki.com/forums/index.ph...ic=426572&st=0

I'm not sure if this will be fixable without pulling the motor out of the car. And IMO if the motor needs to be pulled, the bottom end will simply be replaced with a "built" 2.2L, basically I'd just look into Pauter rods and some upgraded pins for the F22 short block.

If this can be fixed without pulling the motor, that would be even better, but I am planning for the worst and hoping for the best.

here is a link to one other thread of the same occurance https://www.s2ki.com/forums/index.ph...ic=426572&st=0

#3

Registered User

Join Date: Mar 2006

Location: Northern Virginia

Posts: 451

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Billman250,Dec 25 2006, 05:44 AM

What was done to that engine? Gauge install or tap for SC? Looks like a new timing cover.

I will answer for him, just to help out. He did a Defi oil pressure gauge install, and used a tapered fitting, which incidentally caused the crack.

#5

Moderator

I'll give you another tidbit...Defi does not use standard 1/8 NPT (27 tpi) that you can buy all over the place. They use 1/8 BSP which is 28 tpi (threads per inch).

I am not certain the size of the hole in the s2k block. I will check.

I am not certain the size of the hole in the s2k block. I will check.

#6

Registered User

tipical honda crack, most of them happen when using a brassed Tee for gauge/turbo feed line.

well, you could try tig weld it before trashing it, i know a dude jb welded it shut and it's been like that for 3 year+ on sohc d series turbo.

well, you could try tig weld it before trashing it, i know a dude jb welded it shut and it's been like that for 3 year+ on sohc d series turbo.

Trending Topics

#8

Thread Starter

Timing cover isn't new...I just keep the car, and engine clean

As far as the guage, I used whatever adapters Defi supplied, had a stainless braided line made and used a fitting from Ace hardware or where ever to the block. Yes the fittings were brass, and obviously I must have over tightened them...however I honestly do not tighten anything with incredible torque, and am pretty careful about those kind of things.

While the light would be useless, I personally feel uncomfortable without it. Especially with as much track time I partake in. If I'm out on the track, or simply driving down the road and this crack opens up more or starts to leak, it is likely the motor would be destroyed without the light...where as with it, the motor might be salvageable.

While it doesn't look bad, I actually leaked about 2 qts (about 1/8qt over the H before this, and now only the very bottom tip of the dipstick shows some oil) out of this in 45 seconds to 1 minute. If that is the case, it wont take long for it to destroy the motor under load.

And I know that this block can be fixed...the problem is whether or not it can be fixed without taking it out of the car. If I have to take it out, like I said, I'll go 2.2...I will also have this block fixed and sell it. Other then this, it is a perfectly good block.

As far as the guage, I used whatever adapters Defi supplied, had a stainless braided line made and used a fitting from Ace hardware or where ever to the block. Yes the fittings were brass, and obviously I must have over tightened them...however I honestly do not tighten anything with incredible torque, and am pretty careful about those kind of things.

While the light would be useless, I personally feel uncomfortable without it. Especially with as much track time I partake in. If I'm out on the track, or simply driving down the road and this crack opens up more or starts to leak, it is likely the motor would be destroyed without the light...where as with it, the motor might be salvageable.

While it doesn't look bad, I actually leaked about 2 qts (about 1/8qt over the H before this, and now only the very bottom tip of the dipstick shows some oil) out of this in 45 seconds to 1 minute. If that is the case, it wont take long for it to destroy the motor under load.

And I know that this block can be fixed...the problem is whether or not it can be fixed without taking it out of the car. If I have to take it out, like I said, I'll go 2.2...I will also have this block fixed and sell it. Other then this, it is a perfectly good block.

#9

The oil pressure switch port on our cars has 1/8" 28 BSP threads. BSP threads are not tapered. Most aftermarket oil pressure senders (and all that I have ever seen) have 1/8" NPT threads. These threads are tapered. If you start screwing an NPT switch into a BSP port it will screw in fine for about 2 revolutions. After that, the taper puts a tremendous amount of force outward, resulting in a cracked port. I suggest that someone, somewhere put a huge sticky for everyone to see saying,

NEVER EVER SCREW AN AFTERMARKET OIL PRESSURE SENDER INTO THE OIL PRESSURE SWITCH PORT WITHOUT INSTALLING A 1/8" 28 BSP ADAPTER!!

This doesn't help you, but it might help the next guy that tries to do this. You're going to have a very difficult time repairing this without removing the block. Most experienced welders aren't going to want to touch this without removing the engine. You might find someone willing to weld it, but be careful - if something screws up, it's not likely that they're going to assume responsibility.

IMO, you're going to have to completely remove the cracked piece before it can be repaired. If you were to try to just weld the crack on the outside, the remaining crack will act as a stress riser, causing the repair to fail.

NEVER EVER SCREW AN AFTERMARKET OIL PRESSURE SENDER INTO THE OIL PRESSURE SWITCH PORT WITHOUT INSTALLING A 1/8" 28 BSP ADAPTER!!

This doesn't help you, but it might help the next guy that tries to do this. You're going to have a very difficult time repairing this without removing the block. Most experienced welders aren't going to want to touch this without removing the engine. You might find someone willing to weld it, but be careful - if something screws up, it's not likely that they're going to assume responsibility.

IMO, you're going to have to completely remove the cracked piece before it can be repaired. If you were to try to just weld the crack on the outside, the remaining crack will act as a stress riser, causing the repair to fail.

#10

Thread Starter

Originally Posted by slalom44,Dec 25 2006, 05:33 PM

The oil pressure switch port on our cars has 1/8" 28 BSP threads. BSP threads are not tapered. Most aftermarket oil pressure senders (and all that I have ever seen) have 1/8" NPT threads. These threads are tapered. If you start screwing an NPT switch into a BSP port it will screw in fine for about 2 revolutions. After that, the taper puts a tremendous amount of force outward, resulting in a cracked port. I suggest that someone, somewhere put a huge sticky for everyone to see saying,

NEVER EVER SCREW AN AFTERMARKET OIL PRESSURE SENDER INTO THE OIL PRESSURE SWITCH PORT WITHOUT INSTALLING A 1/8" 28 BSP ADAPTER!!

This doesn't help you, but it might help the next guy that tries to do this. You're going to have a very difficult time repairing this without removing the block. Most experienced welders aren't going to want to touch this without removing the engine. You might find someone willing to weld it, but be careful - if something screws up, it's not likely that they're going to assume responsibility.

IMO, you're going to have to completely remove the cracked piece before it can be repaired. If you were to try to just weld the crack on the outside, the remaining crack will act as a stress riser, causing the repair to fail.

NEVER EVER SCREW AN AFTERMARKET OIL PRESSURE SENDER INTO THE OIL PRESSURE SWITCH PORT WITHOUT INSTALLING A 1/8" 28 BSP ADAPTER!!

This doesn't help you, but it might help the next guy that tries to do this. You're going to have a very difficult time repairing this without removing the block. Most experienced welders aren't going to want to touch this without removing the engine. You might find someone willing to weld it, but be careful - if something screws up, it's not likely that they're going to assume responsibility.

IMO, you're going to have to completely remove the cracked piece before it can be repaired. If you were to try to just weld the crack on the outside, the remaining crack will act as a stress riser, causing the repair to fail.

And as far as removing the engine...thats kind of what I assume. Tomorrow I'm going to be calling some places to try and crunch some numbers to find out what will be the most efficient and cost effective way for me to fix this. Assuming I will be swaping the block. Then, when it can see a mechanic...I will know more from there.