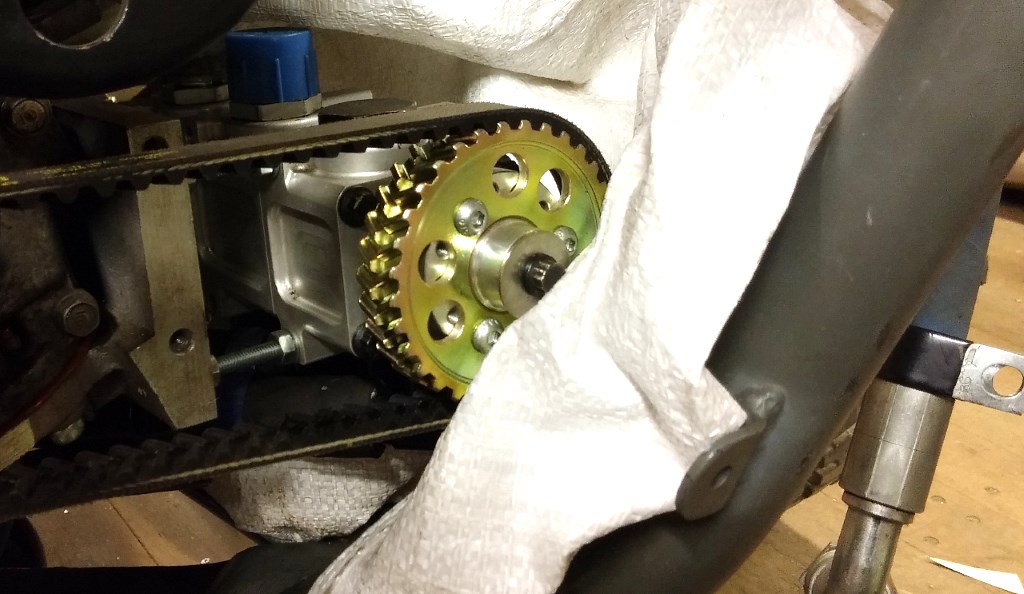

The potential supercharged F20C recipient

#371

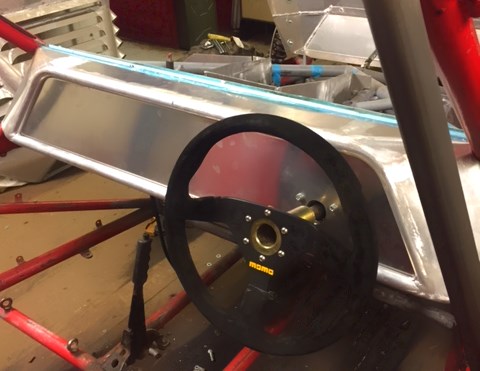

Some reinforcing to the cage to help stiffen things up and make it safer in a roll, just in case, gussets going underneath it in the cross to spread the load.

Downside - no mince pies this christmas!

Downside - no mince pies this christmas!

#372

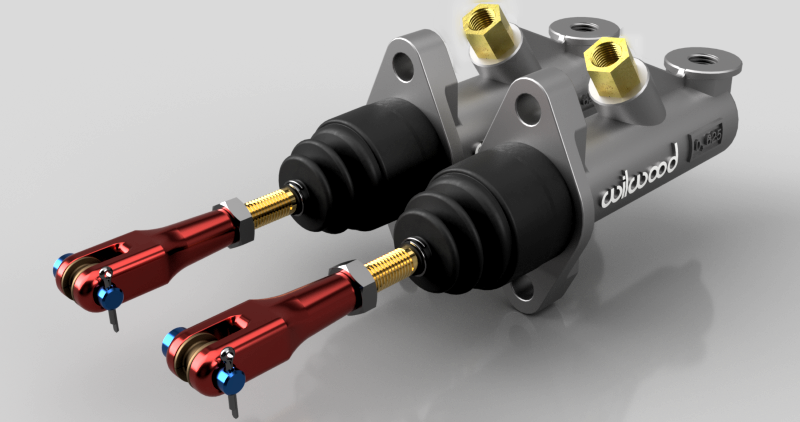

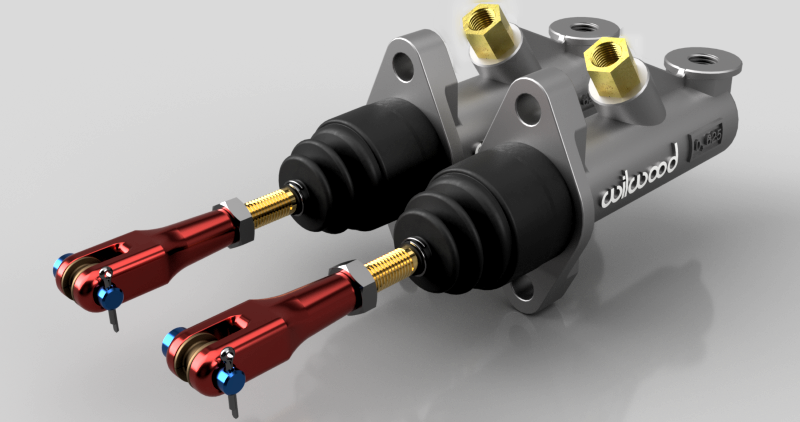

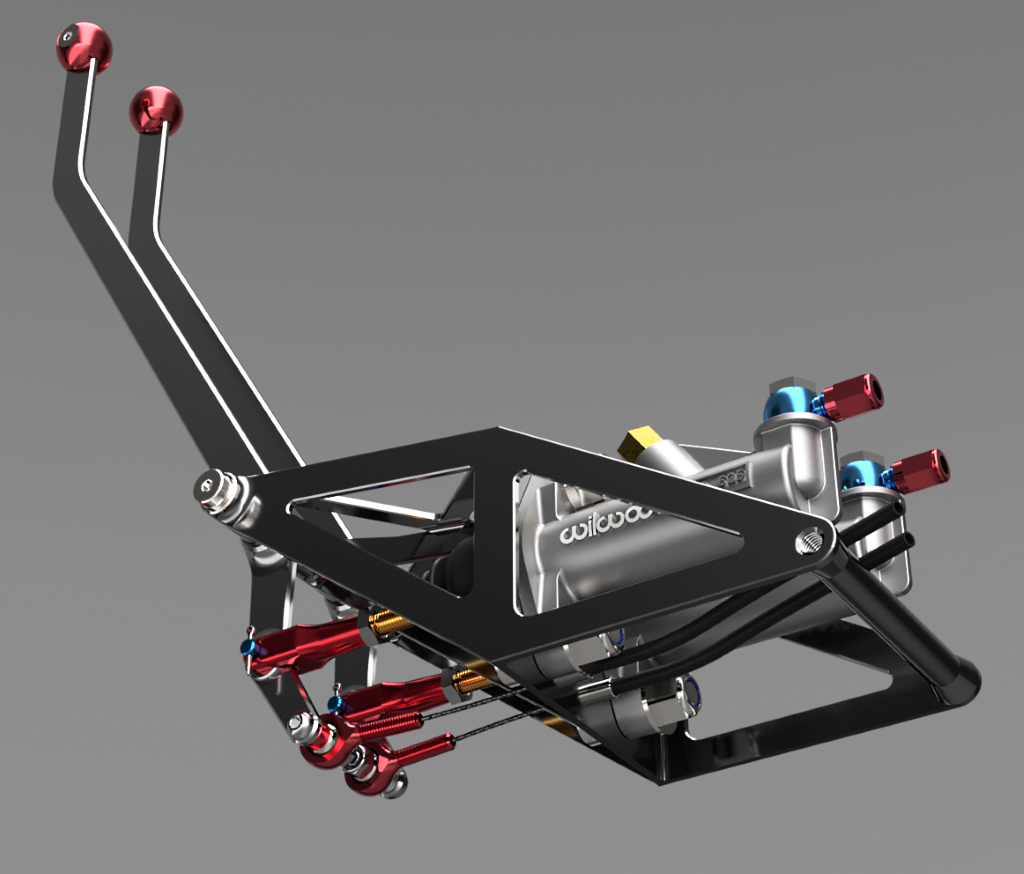

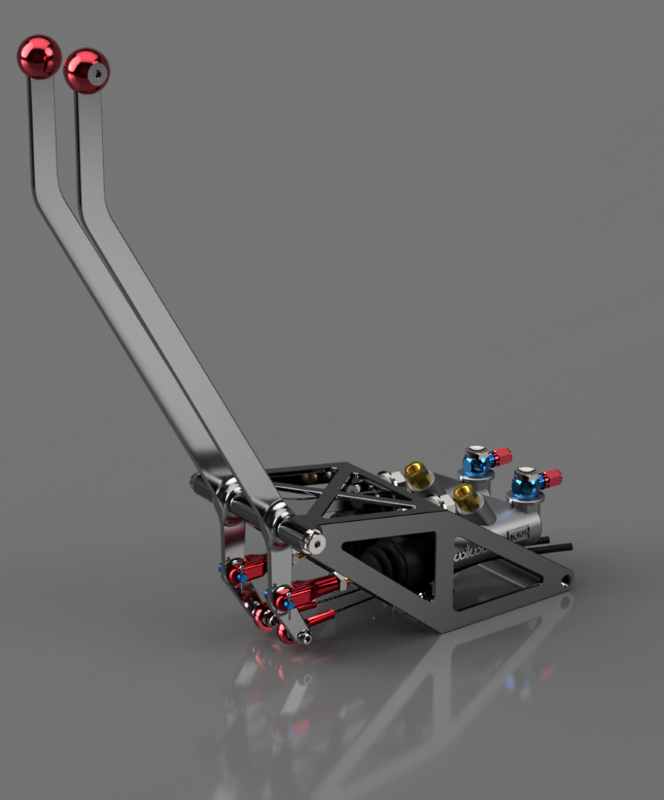

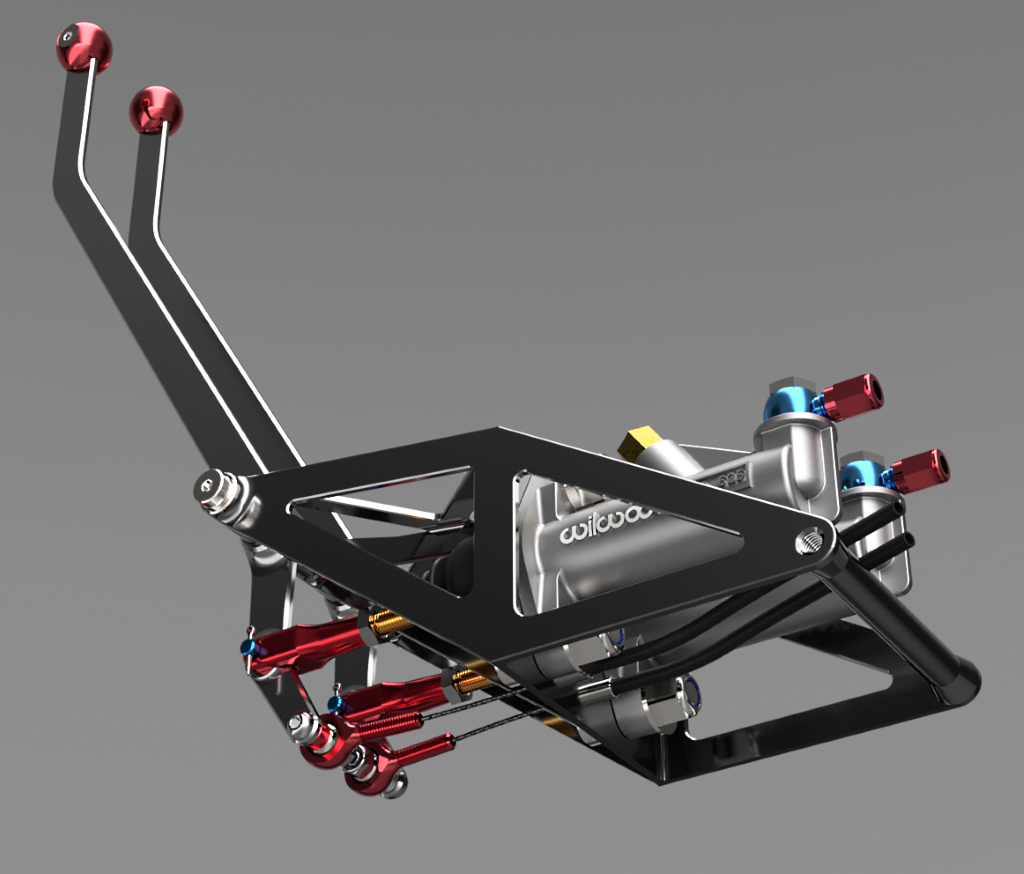

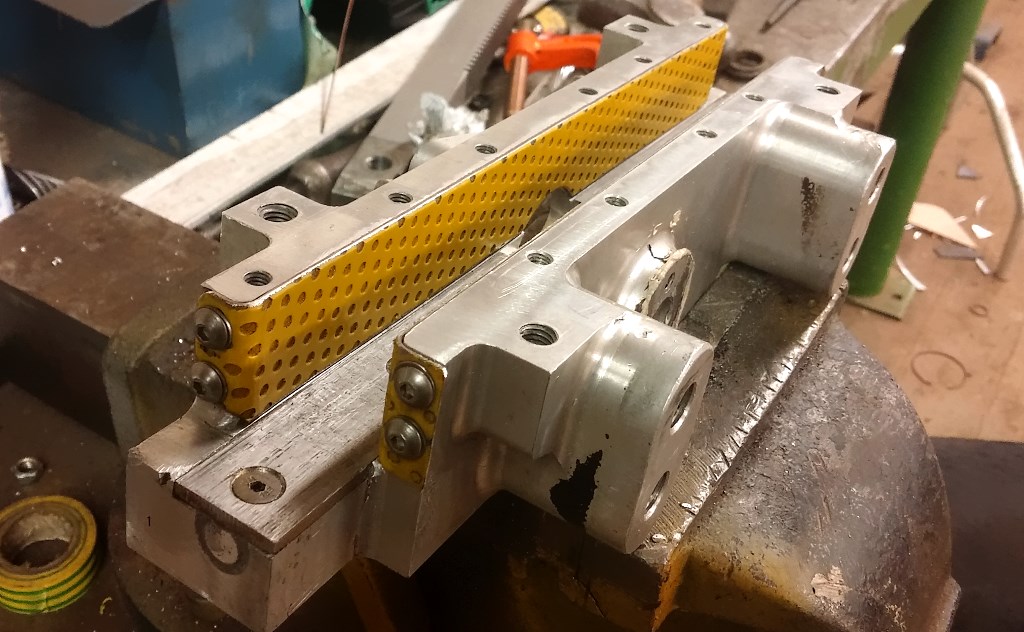

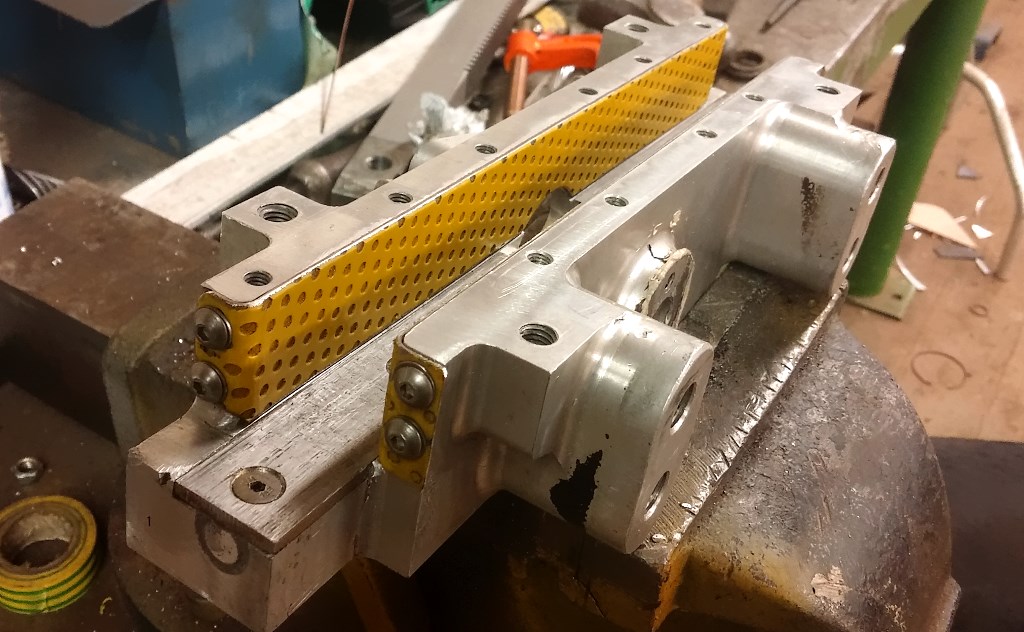

The 'CNC' brand fiddle brakes turn out to need rebuilding yet again, seems to happen with alarming regularity - so decided to ditch them and make our own with less slop, less friction/hysteresis and a few more tricks, work in progress:

Cheaper buying new Wilwood cylinders than it is for the seal kits with the others!

Cheaper buying new Wilwood cylinders than it is for the seal kits with the others!

#373

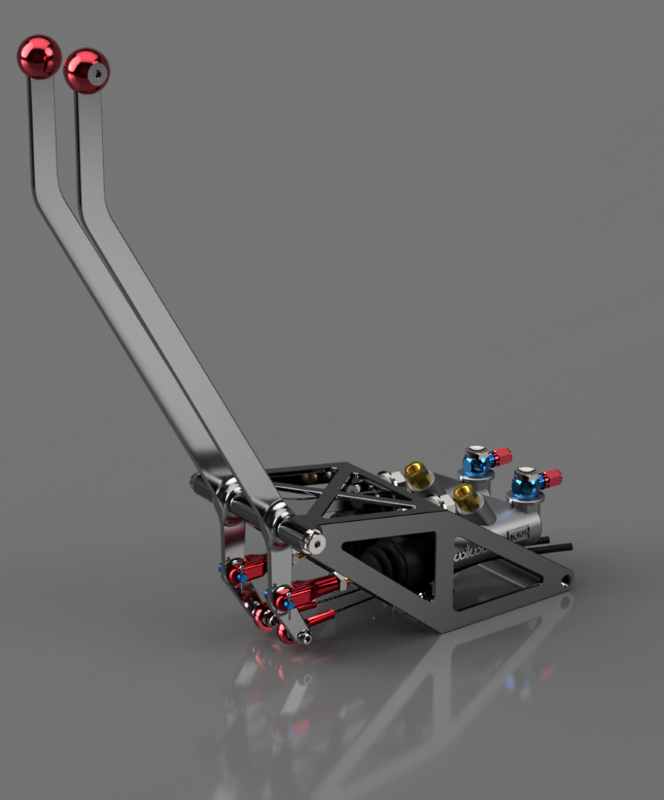

Ah, that's better...now, best buy some more discs for the angle grinder, got a few ally sheets to get through, and some stainless for the handles...they're a lot easier to make on a screen without red hot sparks and dust flying everywhere...

Last edited by BuggyofMildDiscomfort; 11-21-2016 at 01:26 PM.

#374

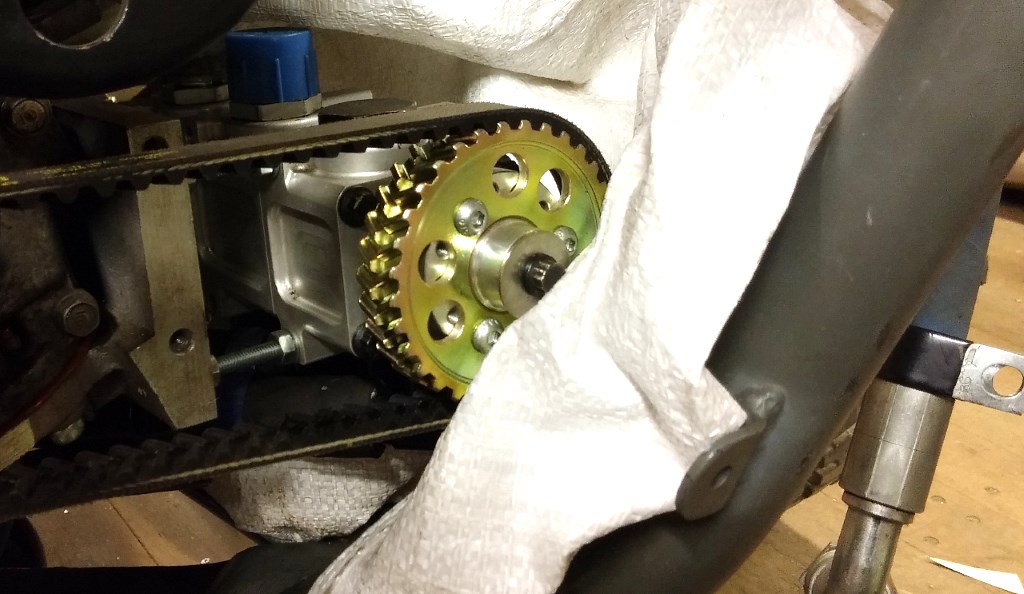

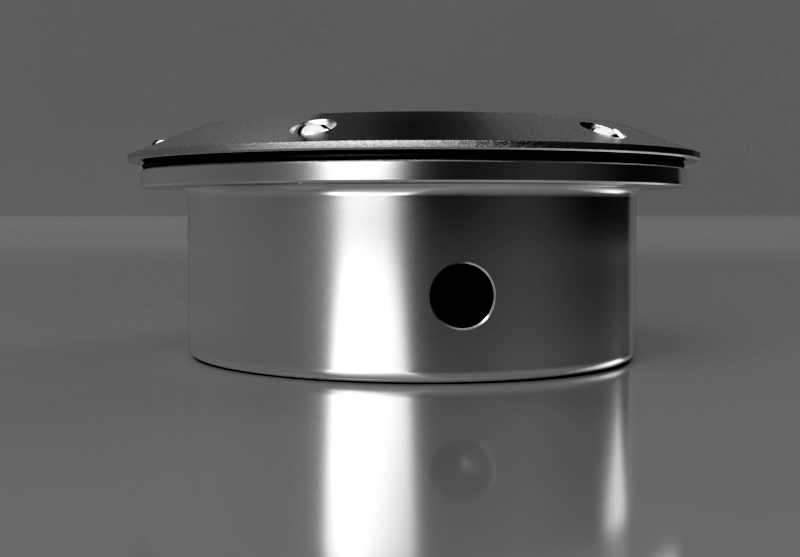

I don't think I was too far out on the CAD render for the dry sump pulley either, back from plating:

Need to make new pump spacers now though, as the eagle eyed may spot.

As if by magic...ta da:

Yes, I have made more than one, before you all start!

A-pillar reinforcement and it's gussets are done, car looks a lot lower without it's normal 96 roof scoops

And roof gusseted at the same time - overkill really up there but regs is regs:

Need to make new pump spacers now though, as the eagle eyed may spot.

As if by magic...ta da:

Yes, I have made more than one, before you all start!

A-pillar reinforcement and it's gussets are done, car looks a lot lower without it's normal 96 roof scoops

And roof gusseted at the same time - overkill really up there but regs is regs:

#375

think there's a leak at the back there

how many miles has this done? it spends more time broken than my SC car haha

those pulleys, do you make them yourself? TTS want about £400 for some idler pulleys for mine (assuming my belt goes again)

#376

The herringbone pulleys I bought a couple of blanks and machined them, the others (supercharger/alternator) are custom made on the lathe.

I think it's only done about 3k miles total since we started!

I think it's only done about 3k miles total since we started!

#377

Racks repaired today, done the same to ours as well (well, similar, countersunk bolted to the top rather than the sides, after machining a suitable housing) as it had some wear starting on the casing, although nothing on the teeth like these:

And we've just finished off making the new dashboard, it's much better than the old one, but unfortunately muggins here forgot to get a photograph, as it was about 1am by the time we locked up to come home - I'll get one in the morning.

The cylinders and plumbing have arrived for the new fiddle brakes so tommorow we'll crack on with making those - probably won't finish it as I have other cars in the workshop for jobs atm and some need to be done in the morning asap - but should get the plates cut if nothing else

And we've just finished off making the new dashboard, it's much better than the old one, but unfortunately muggins here forgot to get a photograph, as it was about 1am by the time we locked up to come home - I'll get one in the morning.

The cylinders and plumbing have arrived for the new fiddle brakes so tommorow we'll crack on with making those - probably won't finish it as I have other cars in the workshop for jobs atm and some need to be done in the morning asap - but should get the plates cut if nothing else

#379

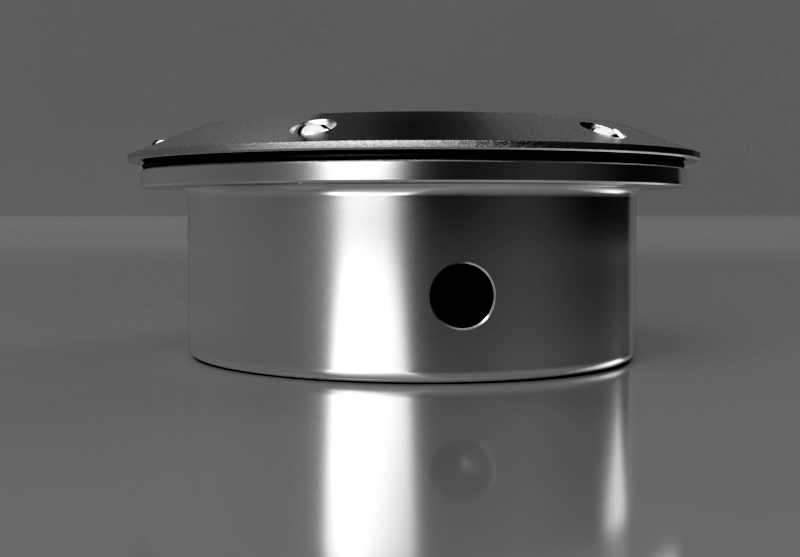

Now, since we can't see the rev counter because - a) It's behind the steering wheel paddles and b) The new mounting ring around the steering column fouls it - then we started the search for another, smaller one.

After several versions of sticker shock and not liking some of the cheaper tat available - which seems to be aimed at getting as many lights as possible in and the crap fonts that you can't read in the dark (Fast and Furious has a lot to answer for) - the next best thing came to mind.

Mount it in the middle of the dash and move the fusebox.

All well and good, unfortunately the ECU is behind the dashboard in the middle at the bottom, and at the top is the windscreen wiper mechanism, and the tachometer is almost 5 inches deep. Bugger.

So, out came the screwdrivers and the soldering iron, the original dial came to pieces and the internals have been shortened, moved or rearranged and re-soldered.

Next step is to machine a new case out of a bit of 5" aluminium pipe and some sheet in the scrap pile, et voila, one half height rev counter:

Should have just fitted a bigger bloody shift light and left it off...

After several versions of sticker shock and not liking some of the cheaper tat available - which seems to be aimed at getting as many lights as possible in and the crap fonts that you can't read in the dark (Fast and Furious has a lot to answer for) - the next best thing came to mind.

Mount it in the middle of the dash and move the fusebox.

All well and good, unfortunately the ECU is behind the dashboard in the middle at the bottom, and at the top is the windscreen wiper mechanism, and the tachometer is almost 5 inches deep. Bugger.

So, out came the screwdrivers and the soldering iron, the original dial came to pieces and the internals have been shortened, moved or rearranged and re-soldered.

Next step is to machine a new case out of a bit of 5" aluminium pipe and some sheet in the scrap pile, et voila, one half height rev counter:

Should have just fitted a bigger bloody shift light and left it off...

#380

Ah, long overdue, but at least this thread is one that photobucket hasn't completely killed...

Anyway, no, we're not dead, yes, we're still working on it, yes, it's almost done.

Taking the panels to be sprayed this week, we've upgraded a fair few bits so I've reworked the wiring to accomodate the new dash, solid state cutoff and sensors, etc.....and just last night I realised that whilst I had the engine in bits I never recut the thrust washers and seated a set on the other side when I replaced the originals.

We need that because we're on a push clutch, rather than a pull, so obviously the loads go the other way into the crank - and having seen how many people have had issues with vibration, pickup and even bearings seizing with some of the push + twin plate upgrades on here, I'm not risking just relying on the oil film between the crank and castings.

So....now I need to pull the engine back out again and do some very quick machine work because she's due on the dyno shortly!

Anyway, no, we're not dead, yes, we're still working on it, yes, it's almost done.

Taking the panels to be sprayed this week, we've upgraded a fair few bits so I've reworked the wiring to accomodate the new dash, solid state cutoff and sensors, etc.....and just last night I realised that whilst I had the engine in bits I never recut the thrust washers and seated a set on the other side when I replaced the originals.

We need that because we're on a push clutch, rather than a pull, so obviously the loads go the other way into the crank - and having seen how many people have had issues with vibration, pickup and even bearings seizing with some of the push + twin plate upgrades on here, I'm not risking just relying on the oil film between the crank and castings.

So....now I need to pull the engine back out again and do some very quick machine work because she's due on the dyno shortly!