Another F24C build

#1

Thread Starter

VTEC-o-philes,

Thought it would be worth putting up some pics of my F24C build.

The aim of this build was to build up a F24C on a limited budget to use in a one off race meeting. The race series I normally race in requires a stock engine. This one off meeting at the Australian Bathurst track was a chance to have a bit of fun.

I decided to use aftermarket rods and pistons as these are cheap to purchase and being new, have a known history.

Build specs were.

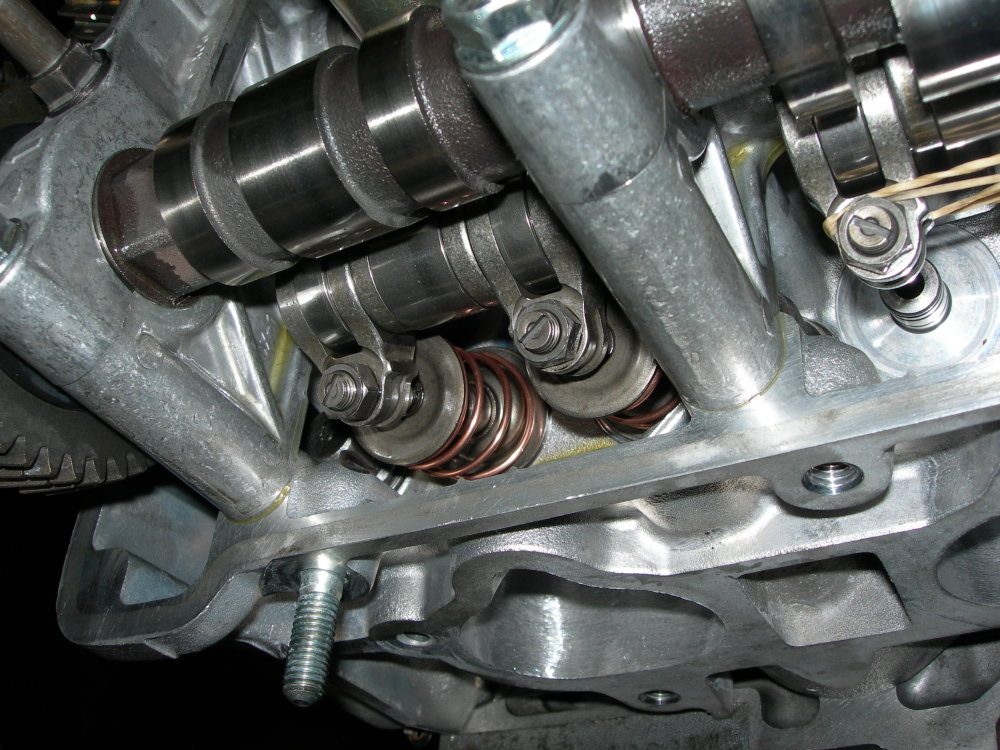

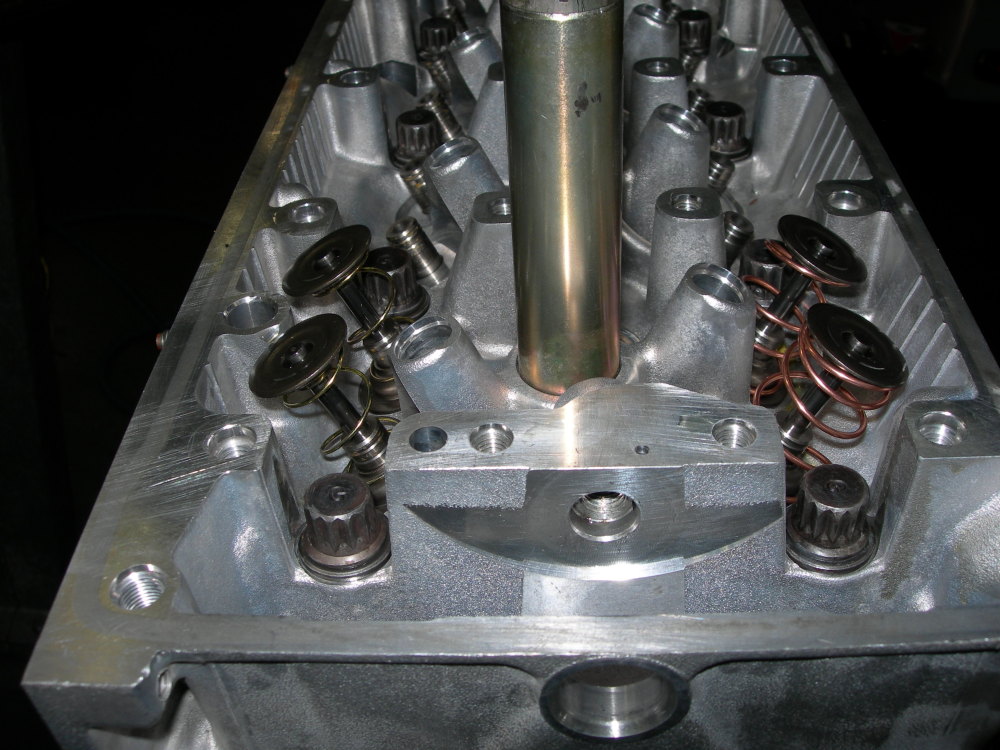

Stock head, lightly ported, cut valve seats, stock springs with titanium retainers.

Stock inlet, cams, valves.

550cc injectors RC tech

AEM ECU

H22 Mahle goldseries pistons to allow me to use stock bores, honed to 87.25mm. Compression targeted to 11.2:1 to run Australian pump fuel.

H22 Probe rods, I beam due to the expected side loads.

Honda K24 crank. ( Honda euro spec)

Attached are some pictures of the build.

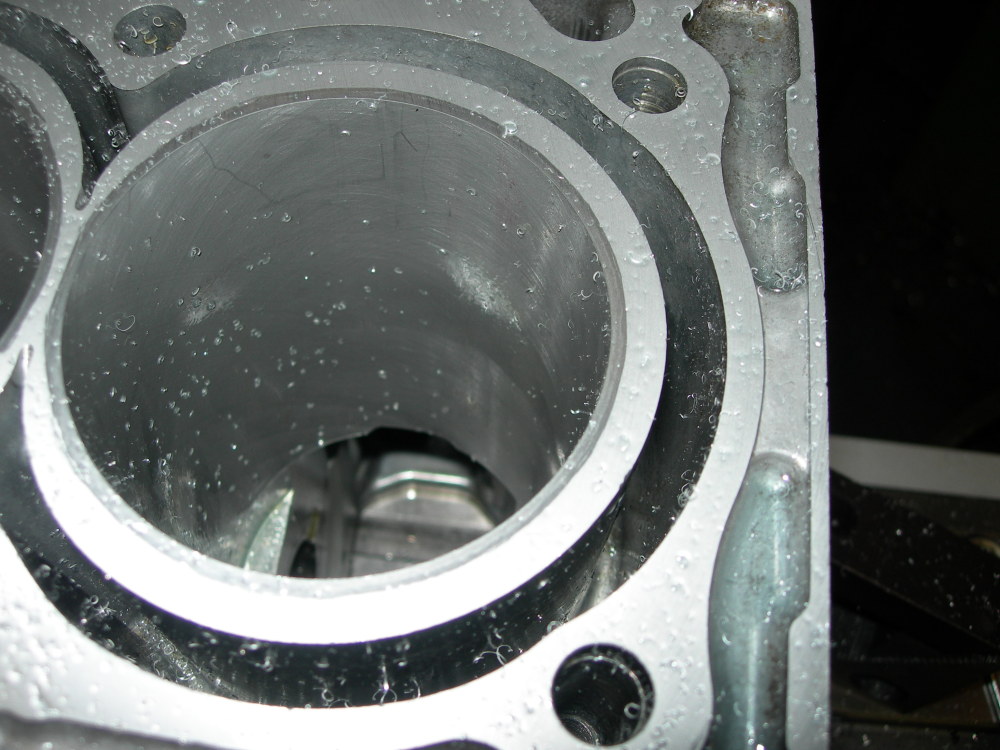

Block with torque plate in place to make sure the bores were under load. It took me a day to make this plate.

After a trial assembly I determined that I would need to take 0.35mm off the deck to get my target compression so next step was to mill the block surface.

There was some handling damage to the block surface so I needed to take material of this surface to ensure a good seal. It also meant my head was near

standard chamber volume if I wanted to use it on another engine later on.

The FRM layer in the bore is surprisingly thick on this block. I reckon you could put 88mm pistons in easily.

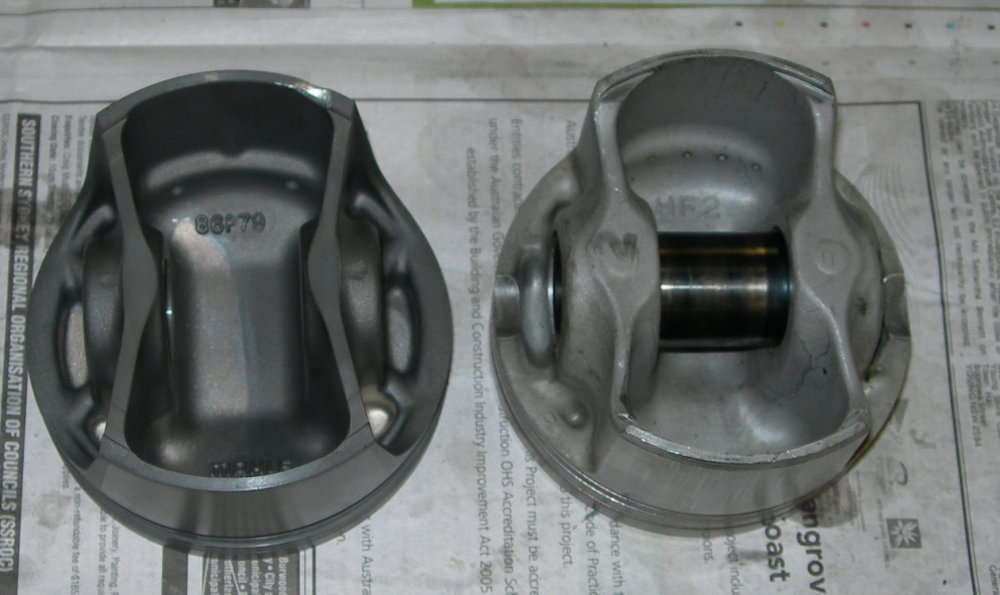

Rods, before/after machining to accept K24 bearings.

Mahle pistons. beautiful products, note the notch for the oil squirters.

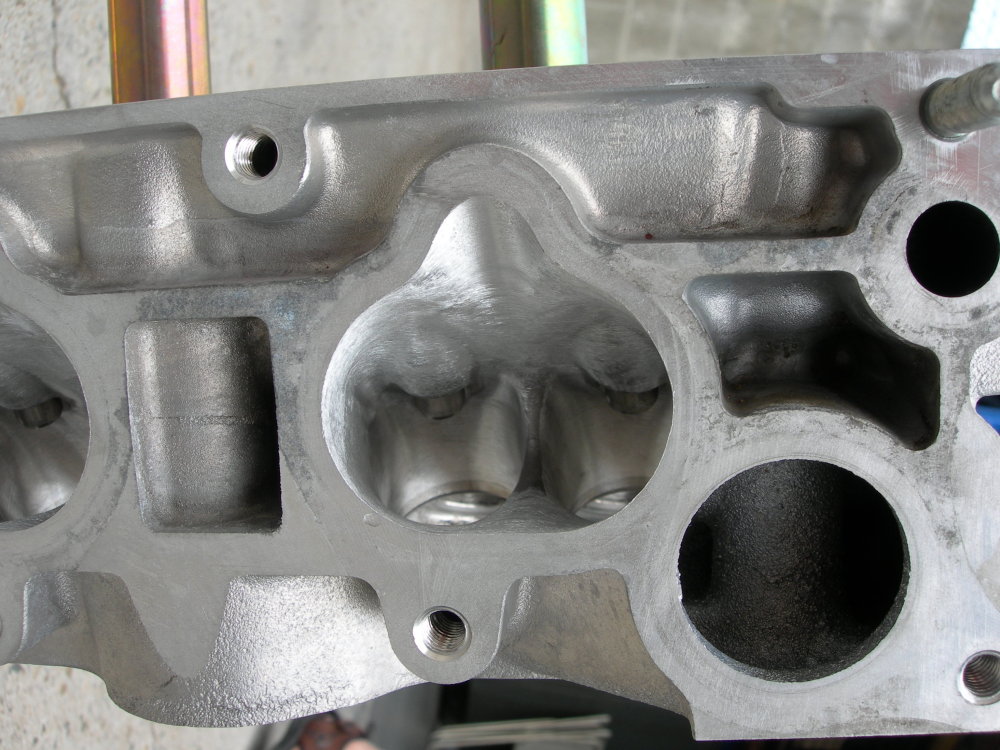

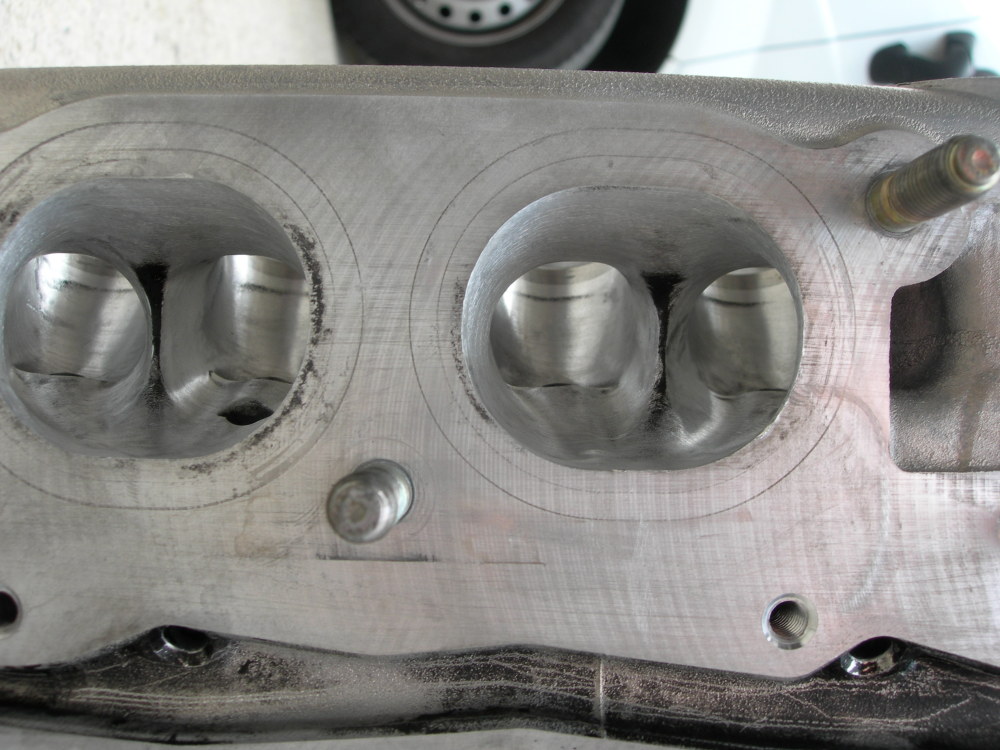

Short block with 1 piston in place. This is so I can check the valve/piston clearances.

Head was ported lightly, valve seats 3 angle cut and deck milled flat.

To check valve clearances I made up some ghetto valve springs from welding wire, and assembled the motor as a single cylinder motor. I swapped the short/long vtec pins around

which locked the VTEC rockers into the high lift position. I could then turn the engine slowly over TDC, and push down on the valves. This

allowed me to feel the valve to pistons clearance as I wound the engine over. Much quicker than messing around with plastercene/clay. I found

I had a truckload of inlet clearance, and just over 3mm exhaust clearance. The exhaust cutouts in the H22 pistons didnt line up with the valves

very well, but there was sufficient clearance anyway.

Well, with the engine together how did it all go.

It took a while to get used to the AEM ECU as I normally use Motec. It took some fiddling, but I got the automapping to work really well. On the dyno

you could just drive to each load cell and watch the fuel values adapt. I was able to do all the light load cells on the road but had lots of wheelspin

problems once VTEC cut in.

I adjusted the VTEC to switch in a 4250rpm. The engine was incredible and would lay black stripes when VTEC cut in. The mid range torque was massive

and it wanted to rev past the 8200rpm limit with ease.

Dyno wise, my car had pulled 190 rwhp on its stock engine. The F24C took a lot of fiddling with the timing (probably due to the short road ratio) to get the torque/power out of it. Once it was tuned I pulled 220 rwhp with a huge amount of torque from 4000rpm to 8000rpm.

On the track the engine was a rocket and I had to fit taller rear tyres as I was redlining in 6th. ( 240km/h). I won one race, and the other two were

washouts. ( slick tyres on a wet track)

With another race next week I've had to pull the F24C and put it on the shelf. Hopefully I'll find some other opportunities to put it back in, otherwise I could

probably be convinced to sell it off.

Thought it would be worth putting up some pics of my F24C build.

The aim of this build was to build up a F24C on a limited budget to use in a one off race meeting. The race series I normally race in requires a stock engine. This one off meeting at the Australian Bathurst track was a chance to have a bit of fun.

I decided to use aftermarket rods and pistons as these are cheap to purchase and being new, have a known history.

Build specs were.

Stock head, lightly ported, cut valve seats, stock springs with titanium retainers.

Stock inlet, cams, valves.

550cc injectors RC tech

AEM ECU

H22 Mahle goldseries pistons to allow me to use stock bores, honed to 87.25mm. Compression targeted to 11.2:1 to run Australian pump fuel.

H22 Probe rods, I beam due to the expected side loads.

Honda K24 crank. ( Honda euro spec)

Attached are some pictures of the build.

Block with torque plate in place to make sure the bores were under load. It took me a day to make this plate.

After a trial assembly I determined that I would need to take 0.35mm off the deck to get my target compression so next step was to mill the block surface.

There was some handling damage to the block surface so I needed to take material of this surface to ensure a good seal. It also meant my head was near

standard chamber volume if I wanted to use it on another engine later on.

The FRM layer in the bore is surprisingly thick on this block. I reckon you could put 88mm pistons in easily.

Rods, before/after machining to accept K24 bearings.

Mahle pistons. beautiful products, note the notch for the oil squirters.

Short block with 1 piston in place. This is so I can check the valve/piston clearances.

Head was ported lightly, valve seats 3 angle cut and deck milled flat.

To check valve clearances I made up some ghetto valve springs from welding wire, and assembled the motor as a single cylinder motor. I swapped the short/long vtec pins around

which locked the VTEC rockers into the high lift position. I could then turn the engine slowly over TDC, and push down on the valves. This

allowed me to feel the valve to pistons clearance as I wound the engine over. Much quicker than messing around with plastercene/clay. I found

I had a truckload of inlet clearance, and just over 3mm exhaust clearance. The exhaust cutouts in the H22 pistons didnt line up with the valves

very well, but there was sufficient clearance anyway.

Well, with the engine together how did it all go.

It took a while to get used to the AEM ECU as I normally use Motec. It took some fiddling, but I got the automapping to work really well. On the dyno

you could just drive to each load cell and watch the fuel values adapt. I was able to do all the light load cells on the road but had lots of wheelspin

problems once VTEC cut in.

I adjusted the VTEC to switch in a 4250rpm. The engine was incredible and would lay black stripes when VTEC cut in. The mid range torque was massive

and it wanted to rev past the 8200rpm limit with ease.

Dyno wise, my car had pulled 190 rwhp on its stock engine. The F24C took a lot of fiddling with the timing (probably due to the short road ratio) to get the torque/power out of it. Once it was tuned I pulled 220 rwhp with a huge amount of torque from 4000rpm to 8000rpm.

On the track the engine was a rocket and I had to fit taller rear tyres as I was redlining in 6th. ( 240km/h). I won one race, and the other two were

washouts. ( slick tyres on a wet track)

With another race next week I've had to pull the F24C and put it on the shelf. Hopefully I'll find some other opportunities to put it back in, otherwise I could

probably be convinced to sell it off.

Trending Topics

#10

Thread Starter

Originally Posted by s2kpearlwhite,Apr 24 2009, 08:02 AM

nice stuff you got there! how does it compares to a 2.4 stroker kit besides the cost savings?

The custom kits will have a better rod/stroke ratio making it safer to rev harder. Some (but not all) retain the F20 width rod bearing rather than use the K24 narrower bearing. The piston is slightly lower in the block, so has less effective squish area. Custom kits also have a lighter race style crank.

The F24C hybrid retains FRM bores which saves a huge expense in sleeves and machining. Even with the short rod/stroke ratio it still seems to make good power up to the flow limits off a standard head package, and there are a few people with a reasonable number of miles on their engines so they seem to last.

My F24C build only had stock cams, inlet manifold and throttle bodies. If cams and ITB's were added the power gains would have been even more dramatic.

Its hard to describe just how much better they are to drive with all the extra torque. The feeling was like jumping out of a 4 cylinder car into a V6 or even small block V8.

Chris.

Thanks for the writeup!

Thanks for the writeup!

see we are not all bling ricers lol

see we are not all bling ricers lol