Measuring toe...

#1

I recently bought the following Longacre "Toe-In Bar" to complement my other alignment gear. I have read the instructions several times and also done a few measurements on my car. I have also read all of the methods described by robrob on his site. The problem that I have with this equipment is that surely it can only measure the overall toe, not the toe left and right? So, if one wheel was toeing in and the opposite wheel toeing out by the same amount, this toe measuring tool would give a reading of zero toe? Is this correct, or am I missing something?

#2

Former Moderator

You are correct. The Toe-In Bar and "scribe line & tape measure" measure total toe. On my site I say to align one end of the car at a time so an unbalanced toe setting will lead to an non-centered steering wheel. Do the rear toe setting then test drive the car to verify a centered steering wheel. That technique was hit or miss so now I use an alignment string to verify equal toe settings (make sure the steering wheel is centered). You can use the toe-in bar to be more precise than the string but the string will show you if your toe is equal on both wheels.

From my website (I realize the op looked at this already):

Measuring Toe-In

From my website (I realize the op looked at this already):

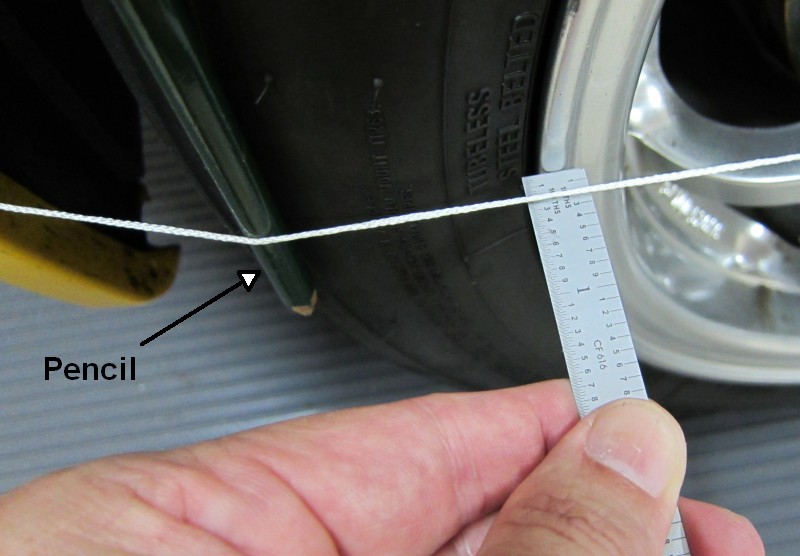

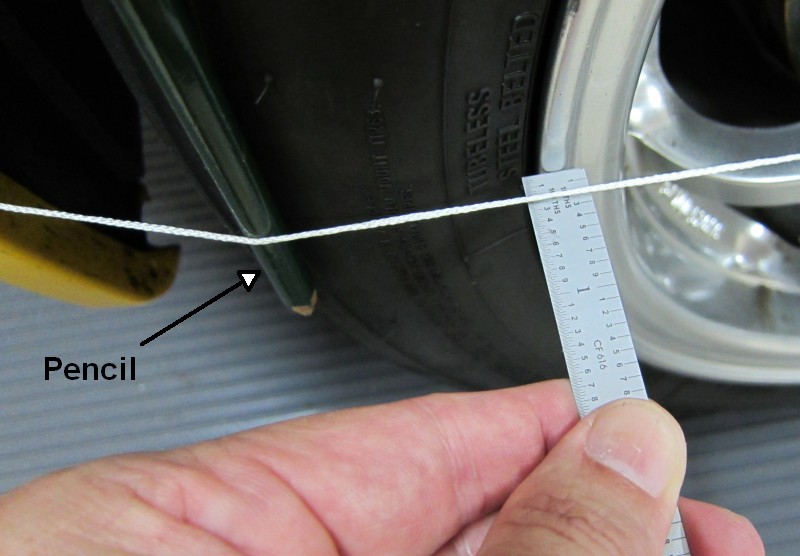

Stringing the Car: A simple way to measure toe is to use string. Your wheels cannot be bent to use this method. You can simply spin them and verify there's no wobble at the rim edge. Start by making sure the steering wheel is centered. I used one long piece of twine with rubber bands on each end. I placed one end on a front bumper splitter mount and wrapped it all the way around the car then put the other end's rubber band on the other splitter mount. The string needs to run through the center of the wheels' hub.

The AP1 S2000's rear end is 2 3/8" (2.375") wider than the front (measured at the wheel mating surface) so the string in the front must be moved 1 3/16" (1.1875") farther off the front wheel to compensate. Don't confuse this measurement with the "Track Width," which Honda says is 1.5 inches wider in the rear. The track width is affected by wheel offset and backspacing.

You can use a dry sponge or sanding block on the front bumper to get the extra spacing required by the narrower front (see pic below). Move the sponge on the bumper to get the correct spacing off the front wheel. In the rear place a pencil under the string to get it out away from the tire sidewall then measure from the rim edge to the string. The distance the pencil holds the string off (average of leading & trailing edge of rim) needs to be added to the front 1.1875" sponge hold off. With 0 toe the measurement at the front and rear of the rim will be equal. If the measurement at the rear of the wheel is larger then there is toe out. If the measurement at the rear of the wheel is smaller it has toe in.

Measuring Toe-In

#3

Thanks robrob. I have seen the method you suggest (using the string line) for measuring toe independently. I thought this method was only accurate when measuring a car with equal track width front and rear? Surely with the S2000 track being wider at the rear, the string has to angle inwards to touch the front wheels?

#4

Former Moderator

I knew the rear track was 1.5 inches wider than the front with the stock wheels but assumed that number would be smaller with a non-staggered setup. I was wrong. After you posted I went out and measured the track and the rear is almost 2 inches wider with CE28N 17 inch wheels and 255 x 4 Nitto NT01s. But even 2 inches of string movement at the rear wheels moves the string at the front wheels one string width. To be more accurate you could replace the pencil used as a string stand-off with something 1 inch in diameter when measuring the front toe.

#5

I place a toe plate against the front wheel and then put a laser level flush against a toe plate so it creates near-vertical laser line. I put a ruler/tape measure perpendicular to the rear hub and the vertical laser line will cross the ruler at some point. that gives me absolute toe.

#6

Rob have you ever actually put your car on a rack to verify what you're doing there and make sure the toe readings you're getting are right? Looks like lots of sources of inconsistency...

I used to do the method you had on your site of doing one end of the car at a time with toe plates. That will get you close, but it really bit me at the national championships this year because the rear wheels were turned by about 1/4". I wouldn't recommend doing it that way.

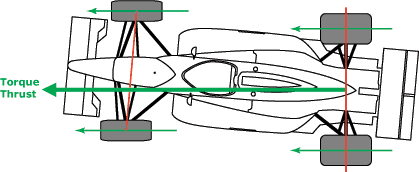

The normal way to string the car is to mount the string independent of the car so that it is a square box. What I used to do is get two pieces of conduit and clamp them to jackstands, and tape string to the ends of the conduit. The conduit served to make sure width of the box was consistent at the front and rear. Then move the jackstands so that the left and right string to hub measurements are equal. They'll be different front to rear because of the different track width, but should be equal side to side to make sure you didn't make a string parallelogram. Then do the method you mention where you measure string to front and rear of the wheel, and then do some trigonometry.

The problem is it takes forever to set up, and also you can't roll the car back and forth, so I'm trying to figure out another method. I'm tempted to just buy the smartstrings

I used to do the method you had on your site of doing one end of the car at a time with toe plates. That will get you close, but it really bit me at the national championships this year because the rear wheels were turned by about 1/4". I wouldn't recommend doing it that way.

The normal way to string the car is to mount the string independent of the car so that it is a square box. What I used to do is get two pieces of conduit and clamp them to jackstands, and tape string to the ends of the conduit. The conduit served to make sure width of the box was consistent at the front and rear. Then move the jackstands so that the left and right string to hub measurements are equal. They'll be different front to rear because of the different track width, but should be equal side to side to make sure you didn't make a string parallelogram. Then do the method you mention where you measure string to front and rear of the wheel, and then do some trigonometry.

The problem is it takes forever to set up, and also you can't roll the car back and forth, so I'm trying to figure out another method. I'm tempted to just buy the smartstrings

#7

Rob have you ever actually put your car on a rack to verify what you're doing there and make sure the toe readings you're getting are right? Looks like lots of sources of inconsistency...

I used to do the method you had on your site of doing one end of the car at a time with toe plates. That will get you close, but it really bit me at the national championships this year because the rear wheels were turned by about 1/4". I wouldn't recommend doing it that way.

The normal way to string the car is to mount the string independent of the car so that it is a square box. What I used to do is get two pieces of conduit and clamp them to jackstands, and tape string to the ends of the conduit. The conduit served to make sure width of the box was consistent at the front and rear. Then move the jackstands so that the left and right string to hub measurements are equal. They'll be different front to rear because of the different track width, but should be equal side to side to make sure you didn't make a string parallelogram. Then do the method you mention where you measure string to front and rear of the wheel, and then do some trigonometry.

The problem is it takes forever to set up, and also you can't roll the car back and forth, so I'm trying to figure out another method. I'm tempted to just buy the smartstrings

I used to do the method you had on your site of doing one end of the car at a time with toe plates. That will get you close, but it really bit me at the national championships this year because the rear wheels were turned by about 1/4". I wouldn't recommend doing it that way.

The normal way to string the car is to mount the string independent of the car so that it is a square box. What I used to do is get two pieces of conduit and clamp them to jackstands, and tape string to the ends of the conduit. The conduit served to make sure width of the box was consistent at the front and rear. Then move the jackstands so that the left and right string to hub measurements are equal. They'll be different front to rear because of the different track width, but should be equal side to side to make sure you didn't make a string parallelogram. Then do the method you mention where you measure string to front and rear of the wheel, and then do some trigonometry.

The problem is it takes forever to set up, and also you can't roll the car back and forth, so I'm trying to figure out another method. I'm tempted to just buy the smartstrings

A string box makes it possible to keep the trust angle in check. A better way would be to utilize toe plates and a laser pointer/distance meter and a ruler. Lay the toe plate and laser pointer flat on the rear wheel/center hub and point it forward. Use a board or ruler coming off from the center hub. Make sure the distance from the hub measures the same on both sides. This makes sure that each wheel in the rear is equal relative to the front axle thus zero thrust.

Meters can be had for 10 bucks. Toe plates or pieces of wood ~$40-50. Ruler ~$5

Trending Topics

#8

Thanks for restating exactly what I described in my post.

A string box makes it possible to keep the trust angle in check. A better way would be to utilize toe plates and a laser pointer/distance meter and a ruler. Lay the toe plate and laser pointer flat on the rear wheel/center hub and point it forward. Use a board or ruler coming off from the center hub. Make sure the distance from the hub measures the same on both sides. This makes sure that each wheel in the rear is equal relative to the front axle thus zero thrust.

http://www.amazon.com/Ultrasonic-Dis...ce+laser+meter

Meters can be had for 10 bucks. Toe plates or pieces of wood ~$40-50. Ruler ~$5

http://www.amazon.com/Ultrasonic-Dis...ce+laser+meter

Meters can be had for 10 bucks. Toe plates or pieces of wood ~$40-50. Ruler ~$5

#10

Former Moderator

I've been trying to get my car on an alignment rack for the last 3 weeks to set the caster and verify my garage settings. My local shop has agreed to let me do the alignment using their rack but I have to wait for a "slow day" at the shop. I'll let everyone know what I find and of course update my website if needed.

I have a laser level so I'll have to give that method a try.

I have a laser level so I'll have to give that method a try.