Wastegates and Boost Control

#1

Registered User

Thread Starter

This Basic wastegate overview should lead you to asking the questions that you really need answered.

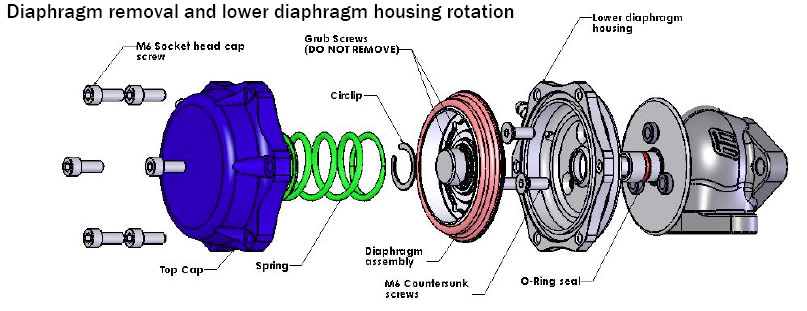

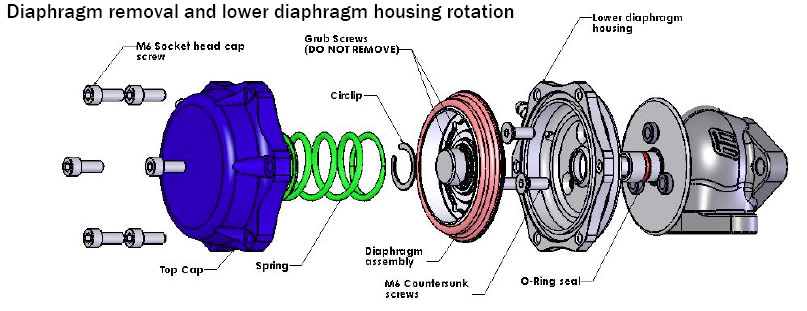

The way a typical two port diaphragm style wastegate works is that the spring holds down the exhaust bypass valve with a force that is greater than the pressure it is rated to hold. The way the valve opens is that the pressure on the valve stem and pressure on the bottom of the wastage create a force which is equal to the sum of the areas times the pressures of each and this works against the spring. This means that the spring pressure is great enough that if you were not to attach any of the vacuum lines it would not open until the pressure was greater than the “Spring Pressure (PSIG)” given by the manufacturer. There is a problem with using this number however, if your manifold is very efficient at the top end then the manifold pressure is low and there is little force created on the valve face alternatively with higher manifold pressures in a manifold like a log the pressure on the valve is greater which generates more force usually this would only make a small difference though. The larger impact usually comes from the losses through the intercooler/piping which changes with every car.

Another piece of the puzzle is wastegate placement and angles which changes the amount of Velocity Pressure. This is a very simple concept the higher the velocity of the gas that is hitting the bottom of the valve the more force that is generated on it. So the less change in the direction of the gasses in the manifold to exit the wastegate the better the control (asuming all other variable are equal).

Finally we have the port size, this is important b/c if the wastegate cannot bypass enough vapor around the turbo then it will start to Creep. The driving force to remove gasses is differential pressure from the manifold to the atmosphere or exhaust system. So the smaller the valve the larger the pressure drop accross it and the less force driving the gases through the wastegate. Consequently if the chosen wastegate has to large or a port the valve flows can flow to much and your boost will spike and fall while b/c the valve is hunting trying to modulate the boost pressure which will rise and fall around the set point erratically, though is not usually a major problem.

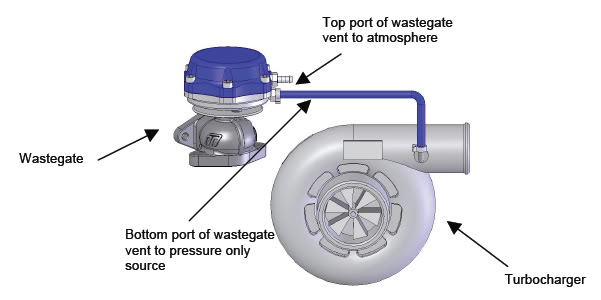

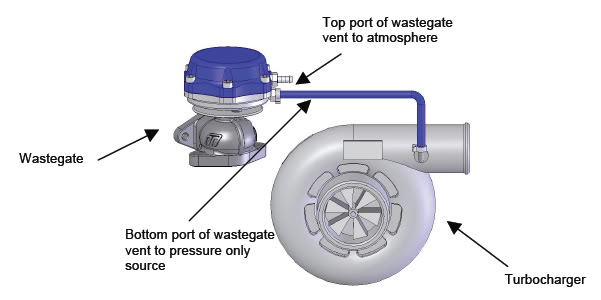

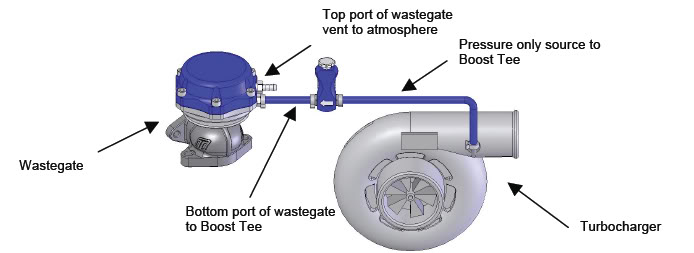

The most basic mode of operation is to attach your vacuum line to the lower port and run off of the manufactures “Spring Pressure” and the top of the wastegate is vented to atmosphere.

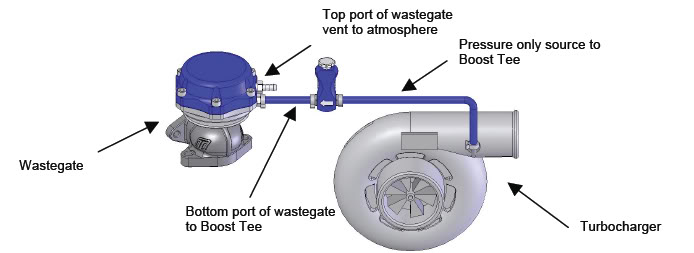

Next, you can bleed boost to the lower port decreasing the total amount of force used to open the valve.

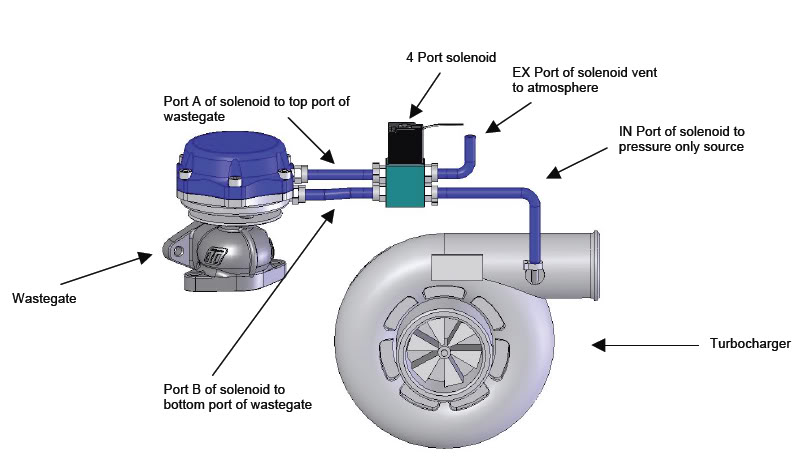

The most typical method of control I see is to use a boost controller to add pressure to the top of the wastegate which creates a force that presses down on the valve. This helps hold the gate completely shut longer allowing for a faster spool. Then when the set pressure is reached the controller vents to atmosphere. One drawback of this method be boost overshoot and lead to a more unstable boost

control.

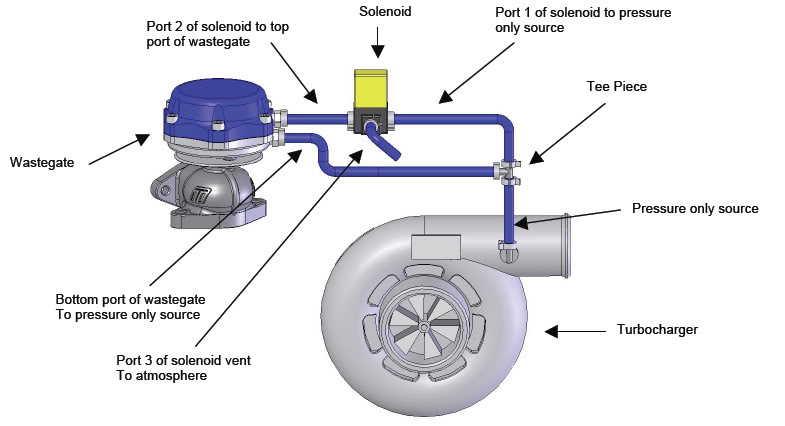

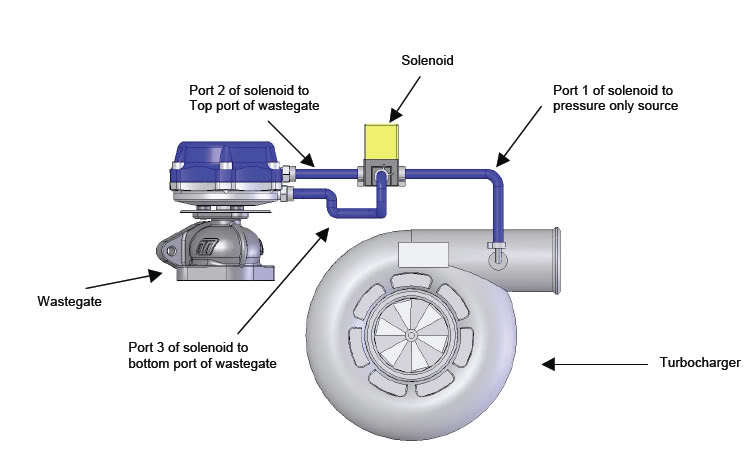

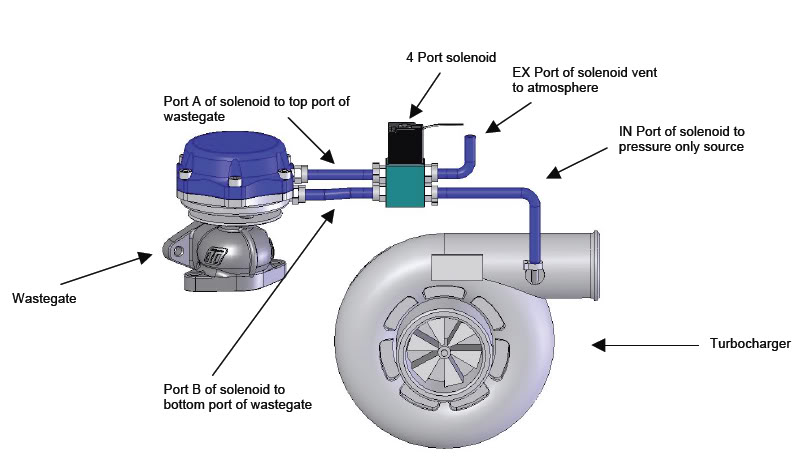

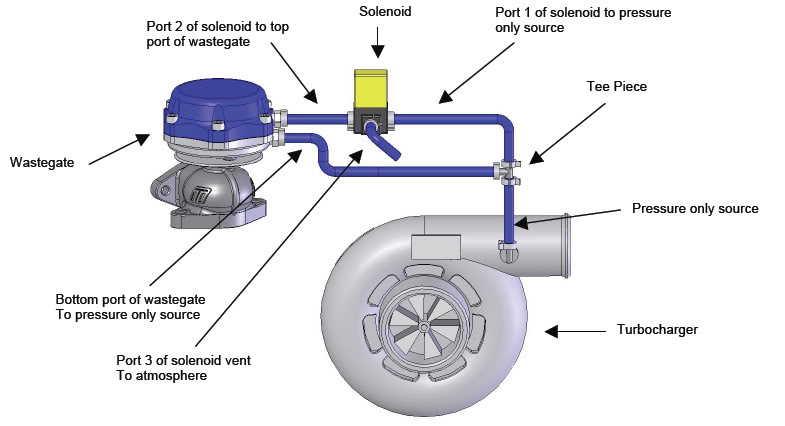

Another method using a AEM/Mac type solenoid is shown below. This method always pressurizes the top port maximizing the pressure downward on the gate. This however will be hard to modulate in most applications and create more boost than many of us can handle.

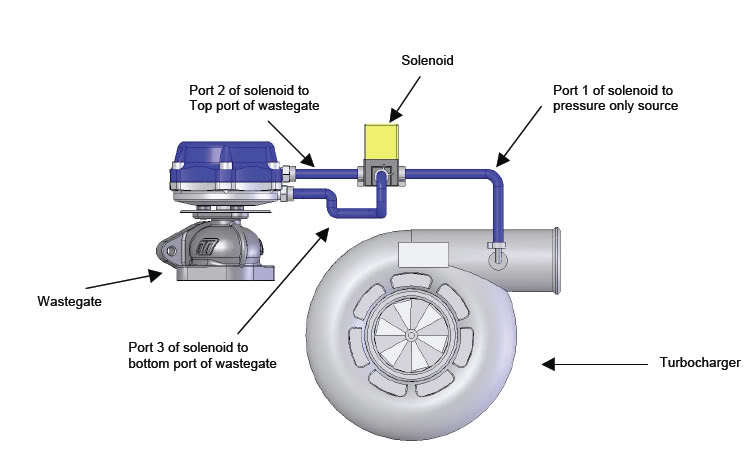

This method is used to run a very wide range of boost pressures though it is difficult to control and requires a good feedback loop to operate accurately and smoothly.

Now there are all kinds of derivatives of these methods but the principal is all the same.

Now, I only spoke a bit about the actual control due to the large amount of controllers available from the basic manual boost controller to the complexities available on most standalone controllers. In general the closer the “Sprig Pressure” is the pressure you want the better. However, options such as boost by gear and High/Low switches drive the user to lower the “Spring Pressures”. My original thought was to put in a small spring and run boost by gear and a Valet mode so I left a 7 psi spring in and increased the pressure through my AEM Boost-A-Gauge and then EMS. However what I found was that unless the feedback loop was very refined in the EMS I was constantly changing the duty cycle to get the correct pressures.

Hope this helps.

The way a typical two port diaphragm style wastegate works is that the spring holds down the exhaust bypass valve with a force that is greater than the pressure it is rated to hold. The way the valve opens is that the pressure on the valve stem and pressure on the bottom of the wastage create a force which is equal to the sum of the areas times the pressures of each and this works against the spring. This means that the spring pressure is great enough that if you were not to attach any of the vacuum lines it would not open until the pressure was greater than the “Spring Pressure (PSIG)” given by the manufacturer. There is a problem with using this number however, if your manifold is very efficient at the top end then the manifold pressure is low and there is little force created on the valve face alternatively with higher manifold pressures in a manifold like a log the pressure on the valve is greater which generates more force usually this would only make a small difference though. The larger impact usually comes from the losses through the intercooler/piping which changes with every car.

Another piece of the puzzle is wastegate placement and angles which changes the amount of Velocity Pressure. This is a very simple concept the higher the velocity of the gas that is hitting the bottom of the valve the more force that is generated on it. So the less change in the direction of the gasses in the manifold to exit the wastegate the better the control (asuming all other variable are equal).

Finally we have the port size, this is important b/c if the wastegate cannot bypass enough vapor around the turbo then it will start to Creep. The driving force to remove gasses is differential pressure from the manifold to the atmosphere or exhaust system. So the smaller the valve the larger the pressure drop accross it and the less force driving the gases through the wastegate. Consequently if the chosen wastegate has to large or a port the valve flows can flow to much and your boost will spike and fall while b/c the valve is hunting trying to modulate the boost pressure which will rise and fall around the set point erratically, though is not usually a major problem.

The most basic mode of operation is to attach your vacuum line to the lower port and run off of the manufactures “Spring Pressure” and the top of the wastegate is vented to atmosphere.

Next, you can bleed boost to the lower port decreasing the total amount of force used to open the valve.

The most typical method of control I see is to use a boost controller to add pressure to the top of the wastegate which creates a force that presses down on the valve. This helps hold the gate completely shut longer allowing for a faster spool. Then when the set pressure is reached the controller vents to atmosphere. One drawback of this method be boost overshoot and lead to a more unstable boost

control.

Another method using a AEM/Mac type solenoid is shown below. This method always pressurizes the top port maximizing the pressure downward on the gate. This however will be hard to modulate in most applications and create more boost than many of us can handle.

This method is used to run a very wide range of boost pressures though it is difficult to control and requires a good feedback loop to operate accurately and smoothly.

Now there are all kinds of derivatives of these methods but the principal is all the same.

Now, I only spoke a bit about the actual control due to the large amount of controllers available from the basic manual boost controller to the complexities available on most standalone controllers. In general the closer the “Sprig Pressure” is the pressure you want the better. However, options such as boost by gear and High/Low switches drive the user to lower the “Spring Pressures”. My original thought was to put in a small spring and run boost by gear and a Valet mode so I left a 7 psi spring in and increased the pressure through my AEM Boost-A-Gauge and then EMS. However what I found was that unless the feedback loop was very refined in the EMS I was constantly changing the duty cycle to get the correct pressures.

Hope this helps.

The following users liked this post:

jimboslice (04-14-2020)

The following users liked this post:

Geniusgza1 (05-27-2019)

#5

I like the diagram and good info here

I'm still trying to get a perfect combination to help with my Full Race manifold so I can get my boost creep under control.

I think the mods should make this a sticky, maybe in the FAQ section ?

I'm still trying to get a perfect combination to help with my Full Race manifold so I can get my boost creep under control.

I think the mods should make this a sticky, maybe in the FAQ section ?

#6

Originally Posted by Jacko,Nov 3 2010, 02:43 PM

I'm still trying to get a perfect combination to help with my Full Race manifold so I can get my boost creep under control.

Trending Topics

#8

Registered User

Thread Starter

Originally Posted by Jacko,Nov 3 2010, 01:43 PM

I like the diagram and good info here

I'm still trying to get a perfect combination to help with my Full Race manifold so I can get my boost creep under control.

I think the mods should make this a sticky, maybe in the FAQ section ?

I'm still trying to get a perfect combination to help with my Full Race manifold so I can get my boost creep under control.

I think the mods should make this a sticky, maybe in the FAQ section ?

Have you talked to Geoff about going to a newer different WG to fit the flange you have or go to a larger?

What about changing up the spring rates?

I have been very happy with Precision's 46mm and Turbosmart has a new Comp-Gate40 that should flow like an older 50mm.

#9

Originally Posted by dsddcd,Nov 4 2010, 10:16 AM

Just to make sure I remember correctly anything over about 19PSI and the smallest change in soleniod duty cycle will make the boost swing wildly?

To be honest I ordered a smaller weight spring but I popped the head gasket before it came in and I had a chance to install it. I'm hoping once I get the car back on the road the lower weight spring will help and I can do some data logs and hopefully Evans and I can figure it out. Other wise I'll need to try other options like you and spectacle have suggested. I need to get it under control because I feel the boost spiking played a major role in the demise of my engine.

#10

Registered User

Originally Posted by spectacle,Nov 3 2010, 10:44 AM

Add a second gate.