How much torque to crack the oil pan?

#1

Thread Starter

I was changing my oil, like I've done a million times. I'm pretty short and skinny, and was using my left hand (I'm right-handed) on my SMALLEST ratchet wrench...

When I torqued it, I heard a gritty, cracking sound (like sand gritting). I undid it -- replaced the washer, wiped and checked with a flashlight -- no visible cracks. I retorqued the drain bolt and this time no cracking sound.

Last post I saw on s2ki when the dude heard a "cracking" sound whilst tightening was indeed an oil pan crack.

So question is, how much torque does it to take to crack an oil pan?

I refuse to believe I hulk-cracked my oil pan with my weak hand, stretched out not even fully under the car, on my smallest wrench. And now I'm paranoid.

When I torqued it, I heard a gritty, cracking sound (like sand gritting). I undid it -- replaced the washer, wiped and checked with a flashlight -- no visible cracks. I retorqued the drain bolt and this time no cracking sound.

Last post I saw on s2ki when the dude heard a "cracking" sound whilst tightening was indeed an oil pan crack.

So question is, how much torque does it to take to crack an oil pan?

I refuse to believe I hulk-cracked my oil pan with my weak hand, stretched out not even fully under the car, on my smallest wrench. And now I'm paranoid.

#2

Join Date: Aug 2012

Location: Foothills East of Sacramento

Posts: 5,601

Received 1,562 Likes

on

928 Posts

If indeed it was cracked by your first attempt, I think it would be very possible not to see the crack. If it is cracked you may not see any effects until you drive it and then take a peak under.

The "cracking" sound is subjective at this point in the written word so it may be problematic comparing a sharp snappy "crack" (oil pan crack) and an ongoing "cracking" sound associated with a grit noise (yours). You may have had the bolt not aligned properly and got the gritty cracking sound as it chewed through a thread or two. You pulled it out and it went back in correctly: no problem now.

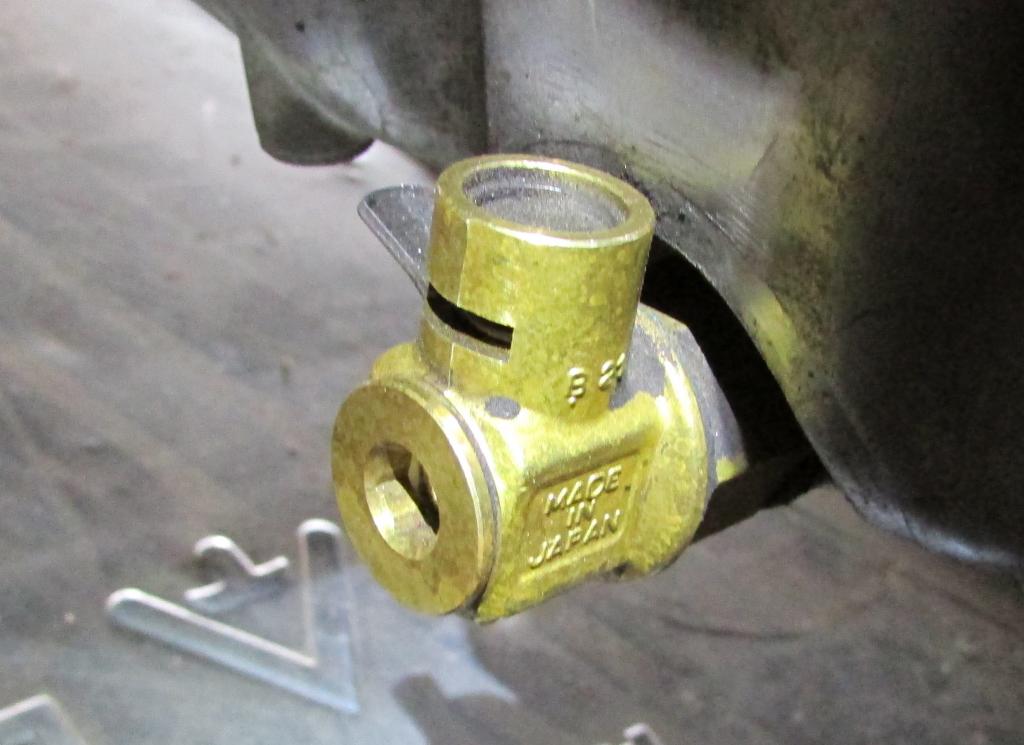

I recommend a Fumoto valve so you won't screw with bolt removal and install, and keep an eye on the pan to see if any oil seeps out from a now unseen crack during operations.

The "cracking" sound is subjective at this point in the written word so it may be problematic comparing a sharp snappy "crack" (oil pan crack) and an ongoing "cracking" sound associated with a grit noise (yours). You may have had the bolt not aligned properly and got the gritty cracking sound as it chewed through a thread or two. You pulled it out and it went back in correctly: no problem now.

I recommend a Fumoto valve so you won't screw with bolt removal and install, and keep an eye on the pan to see if any oil seeps out from a now unseen crack during operations.

#3

The fact that it tightened down the second time tells me it didn't crack, if it was cracked it would not torque down. I usually do it by hand too, just snugging it down, if I used a torque wrench I will go slightly lower than the recommended setting to avoid any potential to crack just in case my torque wrench is off spec.

#5

Seems unlikely you cracked the pan. If you did you will know soon enough.

#6

It doesn't take much with a cast aluminum pan. I know i could do it by hand. The question is, do the threads strip first or does the pan crack. I dont think there are absolutes with cast. Hopefully it was just your crush washer shifting.

#7

Even if its cracked - can't be that hard or expensive to replace?

Trending Topics

#8

lol...it was likely grit in the bolt threads.

Clean off the bolt with brake cleaner before installing. And use a new crush washer every time.

I would assume it would take about 70-80LB.FT or so to start damaging the pan permanently.

Its meant to go for a lifetime of use at 33LB. They're assuming that most people won't use a torque wrench...and will probably end up at 50+LB.

There's quite a few smaller diameter fasteners that exist on the car which people tend to slam down and not crack (bell housing bolts, for example).

If you crack the pan, you probably put quite a bit of power into it....and then realize "omg what am I doing?!" right as you strip the threads. Kind of like Lenny from 'Of Mice and Men', petting those Rabbits. Or a shark whose eyes roll back when it bites into something.

I would say most people that damage the pan have preceded the incident by making a loud grunting noise as they're tightening it with a 1/2" ratchet or longassed wrench or something crazy.

Clean off the bolt with brake cleaner before installing. And use a new crush washer every time.

I would assume it would take about 70-80LB.FT or so to start damaging the pan permanently.

Its meant to go for a lifetime of use at 33LB. They're assuming that most people won't use a torque wrench...and will probably end up at 50+LB.

There's quite a few smaller diameter fasteners that exist on the car which people tend to slam down and not crack (bell housing bolts, for example).

If you crack the pan, you probably put quite a bit of power into it....and then realize "omg what am I doing?!" right as you strip the threads. Kind of like Lenny from 'Of Mice and Men', petting those Rabbits. Or a shark whose eyes roll back when it bites into something.

I would say most people that damage the pan have preceded the incident by making a loud grunting noise as they're tightening it with a 1/2" ratchet or longassed wrench or something crazy.

#9

Thread Starter

That's what I meant -- I've always been more of a George, than a Lennie, when it comes to Of Mice and Men.

No leaks on the garage floor today. Hoping it was grit either in the bolt or washer (which I cleaned!) or the wrench itself.

I know I've torqued it way tighter, using my dominant hand, in oil changes past. And I know quick lube places use impact tools, so that's why all this came as a surprise.

I'll keep an eye out for an oil leak, which I assume will be the only symptom to watch for, barring a catastrophic failure (right? right?!!!!).

Always an adventure with the S. Thanks everyone! :P

No leaks on the garage floor today. Hoping it was grit either in the bolt or washer (which I cleaned!) or the wrench itself.

I know I've torqued it way tighter, using my dominant hand, in oil changes past. And I know quick lube places use impact tools, so that's why all this came as a surprise.

I'll keep an eye out for an oil leak, which I assume will be the only symptom to watch for, barring a catastrophic failure (right? right?!!!!).

Always an adventure with the S. Thanks everyone! :P