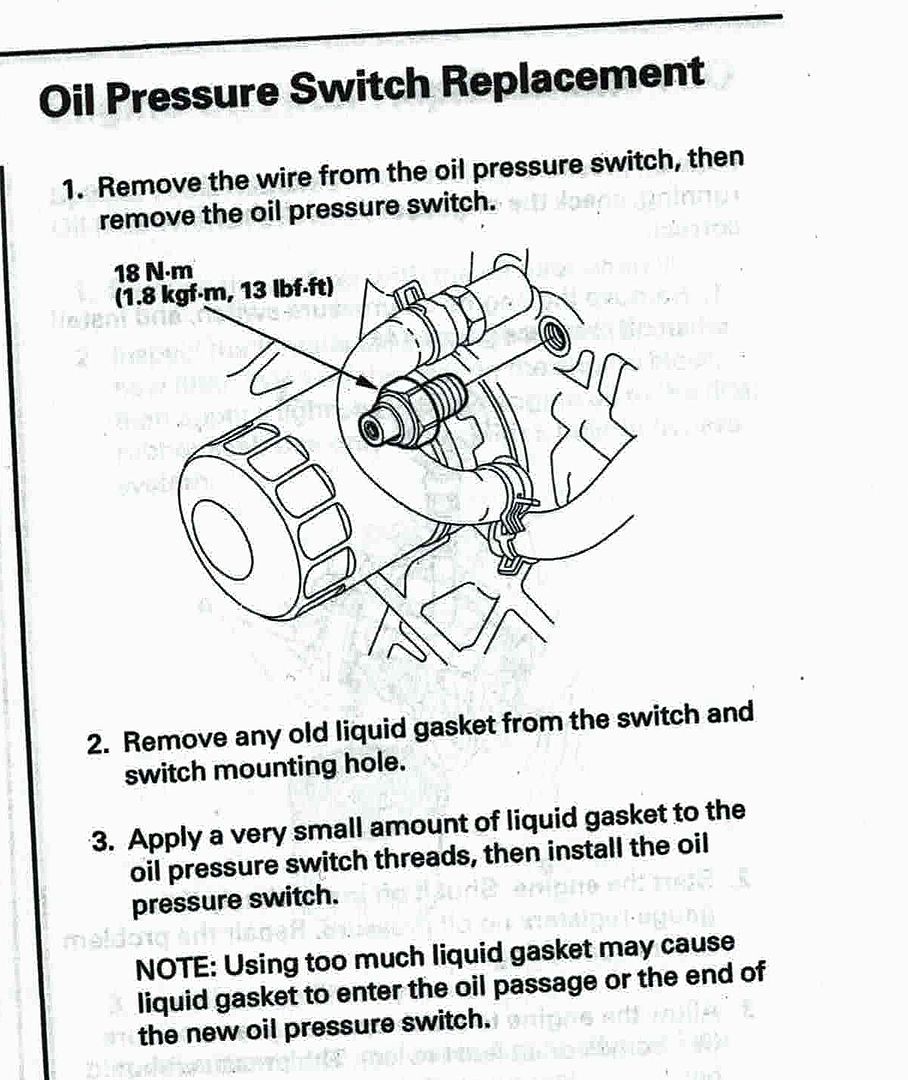

oil pressure switch torque spec

#1

Hi guys, searched around but can't find any info, not even in the service manual. Does anyone know what is the torque spec for the oil pressure switch on the block?

#2

There is no torque spec as it is pipe threads. The seal is completed by adding Hondabond to the threads. I usually thread in by hand until it stops (using socket), and then go another 1/4-1/2 turn with a ratchet. Over tightening can crack the block, so be very careful.

#3

There is no torque spec as it is pipe threads. The seal is completed by adding Hondabond to the threads. I usually thread in by hand until it stops (using socket), and then go another 1/4-1/2 turn with a ratchet. Over tightening can crack the block, so be very careful.

#4

Like I said, it does not have a torque spec. It is pipe threads, 1/8 BSPT to be exact. Follow my tightening instructions and you will not have any issues with leaks or with it cracking your block. If you use a long ratchet such as a torque wrench, you'll be sure to over tighten and strip it out or crack the block. There's almost no torque on it due to it being pipe threads. The sensor doesn't stop like a traditional fastener so you're not going to get any real feedback like you would with a standard hex bolt.

#6

Sure, i perfectly understand what you are saying, i am familiar with tapered threads, but when it's going into an aluminum engine block i like to take all necessary measures  I just now tightened it hand tight and then some more. It's not just to not overtorque but also to not undertighten and have it come lose from engine vibration loosing all your oil pressure. (i know i know, too much talk for a small thing, i like to be very precise at all the jobs i am carrying on my cars, and esp engine related)

I just now tightened it hand tight and then some more. It's not just to not overtorque but also to not undertighten and have it come lose from engine vibration loosing all your oil pressure. (i know i know, too much talk for a small thing, i like to be very precise at all the jobs i am carrying on my cars, and esp engine related)

I just now tightened it hand tight and then some more. It's not just to not overtorque but also to not undertighten and have it come lose from engine vibration loosing all your oil pressure. (i know i know, too much talk for a small thing, i like to be very precise at all the jobs i am carrying on my cars, and esp engine related)

I just now tightened it hand tight and then some more. It's not just to not overtorque but also to not undertighten and have it come lose from engine vibration loosing all your oil pressure. (i know i know, too much talk for a small thing, i like to be very precise at all the jobs i am carrying on my cars, and esp engine related)

#7

Although there ARE recomended torque settings for tapered threads as i am finding out just now with a simple google search : http://www.searsfitting.com/pdf/Brit...ad%20Types.pdf

Trending Topics

#9

#10

Moderator

The book is not gospel, don't even think about putting a torque value to this pipe thread. Torque specs are a guide, not a science. There are too many variables that can affect the outcome.

You stand a VERY good chance of cracking the block with a torque wrench.

You stand a VERY good chance of cracking the block with a torque wrench.