Another new S2000 rumour

#13

Originally Posted by ade73,Oct 1 2004, 10:30 PM

This hand built stuff gets me

Pretty much all cars are hand built even the shitty micra.

Theres a bunch of japs on a production line, no big deal!

Pretty much all cars are hand built even the shitty micra.

Theres a bunch of japs on a production line, no big deal!

you ever worked in the car industry?

#16

Originally Posted by Chris Type R,Oct 2 2004, 08:38 AM

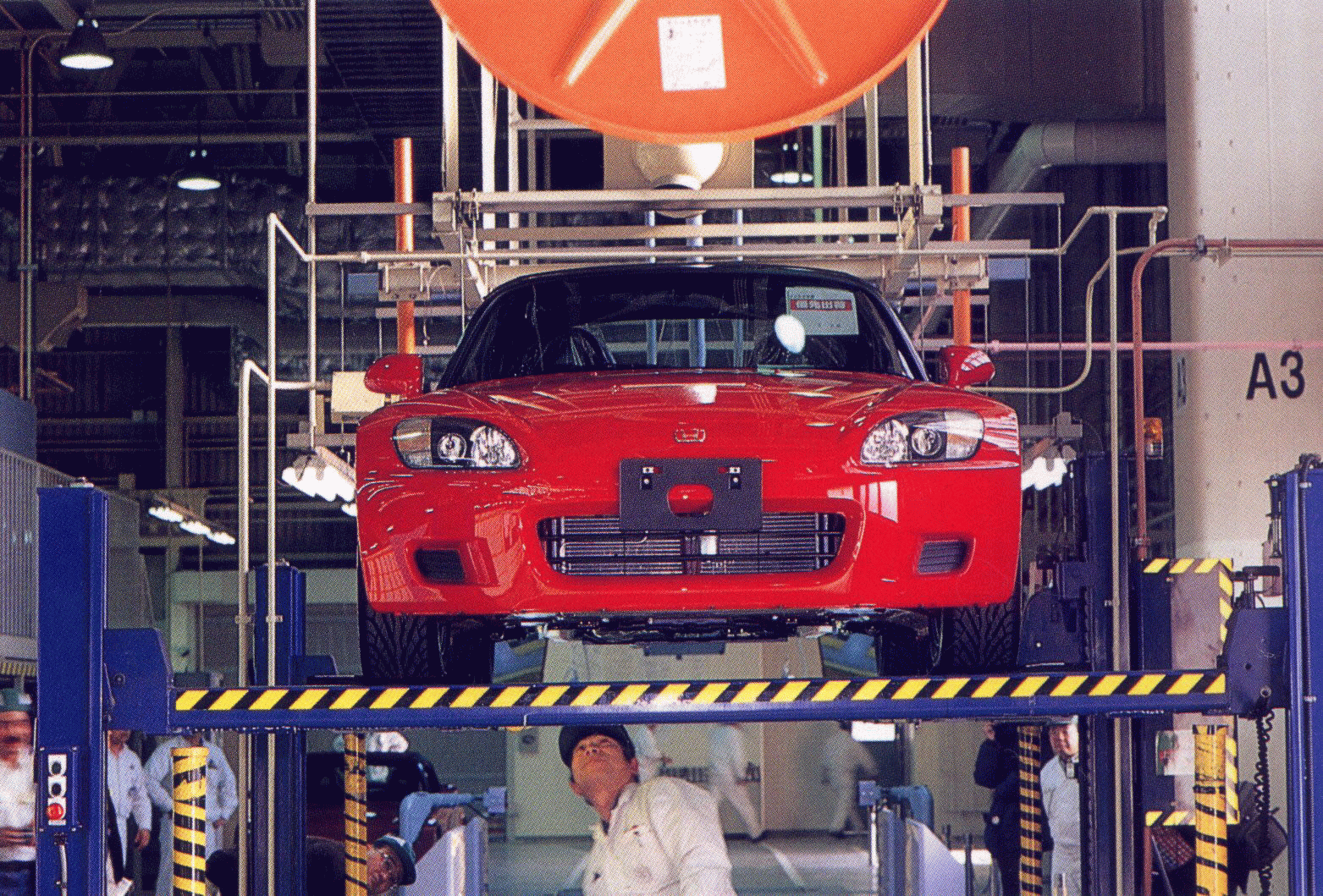

Wouldn't mind letting the two chaps in the first photo know what I think about the diameter of the speaker wire that they're installing

#17

Originally Posted by cheshire_carper,Oct 2 2004, 06:50 AM

Ade,

you ever worked in the car industry?

you ever worked in the car industry?

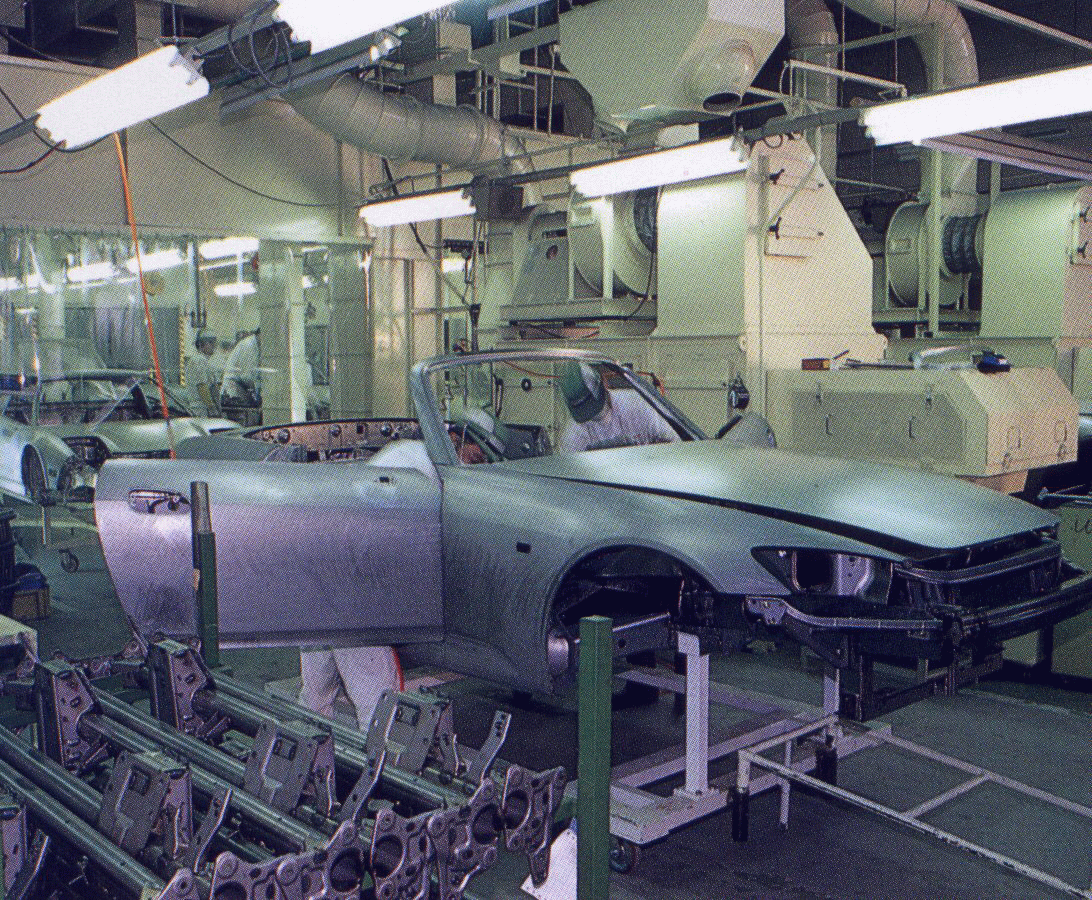

The cars in that picture are on whats commonly refered to as a dolly, with people putting everything together by hand, mass produced car plants normally have a automated line of these dollies or carriers and people putting the car together by hand.

Same principle just on a bigger scale.

As for photos of japs doing that id have to go to one of the jap plants where the micra(march) is built, or ask at sunderland for permission to do this.

#18

I heard from my dealer that

- the S is likely to finish in 2006, as honda are now moving to 6 year life cycles, with a facelift during the 3rd year.

also, the new honda legend will have a 300bhp 3litre engine, guess it being a v6 vtec.

I can believe it.

- the S is likely to finish in 2006, as honda are now moving to 6 year life cycles, with a facelift during the 3rd year.

also, the new honda legend will have a 300bhp 3litre engine, guess it being a v6 vtec.

I can believe it.

#19

If someone says "hand built" it normally means that one person essentially builds the whole part themself (maybe with some assistance) this means you need a highly skilled person who can do every job. They're more likely to spot any defects and the part should come out to nominal specs.

A production line built part has a number of people who don't require such high skill levels. They only need to put a small number of components together so can easily be trained.

Both systems work well which is why we use it with engines. Most are produced off the production lines but once per day we handbuild an engine by a highly skilled member to confirm the quality.

Ade, as for getting access to a plant to get photo's. Unlikely. Unless you've a good reason to come and view (i.e. you supply parts to one) are visiting on training (and paying a lot of money for the privalige) we can't really get people on-site. Was trying recently since a friend wanted a look around a car plant. Dunno what Nissan are like though

A production line built part has a number of people who don't require such high skill levels. They only need to put a small number of components together so can easily be trained.

Both systems work well which is why we use it with engines. Most are produced off the production lines but once per day we handbuild an engine by a highly skilled member to confirm the quality.

Ade, as for getting access to a plant to get photo's. Unlikely. Unless you've a good reason to come and view (i.e. you supply parts to one) are visiting on training (and paying a lot of money for the privalige) we can't really get people on-site. Was trying recently since a friend wanted a look around a car plant. Dunno what Nissan are like though

#20

Originally Posted by ade73,Oct 2 2004, 10:10 AM

Yup i sure do, trained mechanic and now work in the manufacturing business.

As to the handbuilt concept, Fluffys on the ball, pioneered by Mr Ford and referred to today as 'Fordism'. Now perfected by every company in the world.

Whether its cars, processors, washers or burgers.