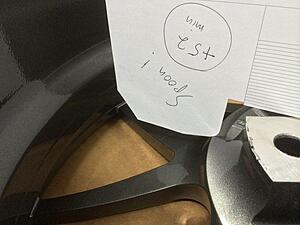

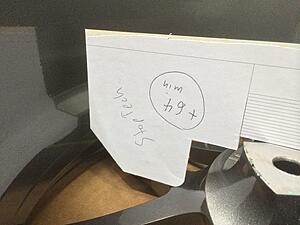

Forgestar F14 17x10, data thread

#1

Update, 2016-04-16:

Left front wheel broke after 14 track days. Fatigue cracking leading to spoke failure. Yikes. Fortunately, the damage to the car was relatively minor, and I got a funny video out of it.

[media]http://www.youtube.com/watch?v=vtYjujhW27Q[/media]

https://www.youtube.com/watch?v=vtYjujhW27Q

Forgestar reached out to me soon after this happened, and offered to refund me the purchase price of the wheels and even paid for the balljoint that got damaged on my slide into the dirt. That was unexpected considering I was using them as dedicated track wheels, and pretty cool of them!

There's been a lot of investigation into this failure by myself and other users, I'll do the best I can to summarize here.

Firstly, and this is the major takeaway from this failure--always inspect any wheel for fatigue cracking, and for that matter, regularly inspect every heavily loaded component on a track/race car. Every aluminum wheel will eventually fail in this manner, although "when" is a very tough question to answer. Wheel manufacturing technique, tire type, track quality, car setup, driving technique, etc, will all effect longevity. Fix some of those variables, and some wheels will last longer than others.

I was surprised that these failed after 14 track days, but these wheels had cracks that were propagating from the backsides of the spokes for some time before they failed. I routinely half-assed my wheel inspections by checking to see if there were any cracks on the outside of the spokes as they were mounted on the car. I wouldn't have had a complete failure on-track had I unmounted the wheels and inspected them thoroughly!

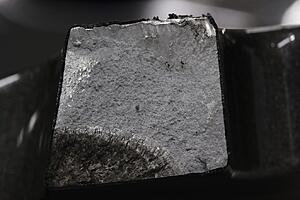

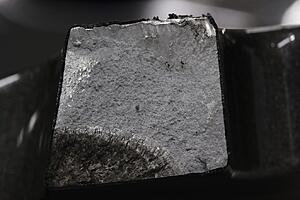

Fatigue Surface

Here are some pictures of the spokes on the failed wheel. The dark section is the result of corrosion of a pre-existing crack. The "fresh" metal is from the total failure. This is the normal appearance of a fatigue crack (on any surface or material). All of the spokes had such fatigue cracks.

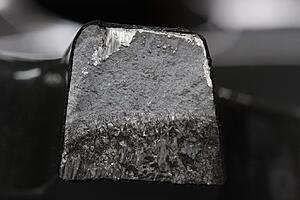

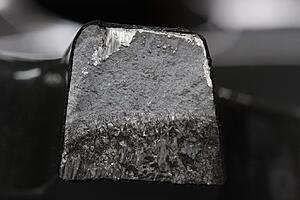

Cracked Spokes

Here are some pictures showing the back-side of the spokes on the remaining wheels, these are the type of cracks that you should look for during inspections.

Car Setup and Usage

Seeing as there are a large number of variables that go into the longevity of a wheel, I will do my best to summarize what characterized my usage:

Basics: Wheels lasted 14 track days. Failure at left front. Very minor cracking on right front. Moderate/heavy cracking on both rears.

These wheels were the thin-spoke version of the Forgestar F14, with a 1400lb load-rating stamp. I'll get into the two versions later in this update.

Car basics: ~2800lbs with driver, half tank. Moderate aero--rear wing and splitter.

Suspension: KW v3 (475lb springs), standard ride height. Eibach front and rear swaybars. Buddy club balljoints. Regarding this particular combination-- with KW v3 and Buddy Club ball joints, and adjusting the ride height back to "normal" with the adjusters, results in coil bind PRIOR to bumpstop engagement on the front. I found this out on a particularly hard curb hit that collapsed the spring perch on the right front shock. The KWs use a glass-filled nylon adjuster with a steel reinforcement band. The plastic threads sheared off the adjuster. After this occurred, I added a bumpstop spacer to ensure the bumpstop worked as it should. This is a curious data point, as this wheel was the least cracked of the 4.

Tires: 6 days on R888, 6 days on RS3, 2 days on RE71R, all 255/40-17

Tracks: Buttonwillow and Auto Club, although one day on the RE71R was at Willow Springs.

General driving: this is all very subjective, but I don't baby the car around curbing? I have some videos of my driving here, but it's kind of hard to make sense of how hard I hit curbing-- https://www.youtube.com/user/cgwiita

Offs: I had 5 offs that I would consider "major". They are:

1. BW 13CW, off at Bus Stop, debeaded rear left (tank slapper, slid off track surface to the left) [Update 2014-04-18: wheels were switched left to right after this incident during tire change from R888 to RS3. So this off debeaded what became the rear right]

2. BW 13CCW, overshot Bus Stop (dropped left wheels off the curbing), underbody scraped on the edge of the curbing

3. BW 13CCW, missed braking point on Sweeper, straight 4 off

4. BW 13CW, dropped right front into curbing on inside of Riverside. As mentioned above, this resulted in a sheared adjuster collar as a result of spring coil bind (due to the combination of KW v3 and Buddy Club ball joints).

5. WSIR, missed braking point turn 9, 4 off

I thoroughly inspected the right front after incident #4 as I was sure I had bent or cracked it, and didn't see anything alarming. Curiously, this is the best condition wheel by far, having only very small cracks near the hub on only a few spokes. I most likely didn't inspect the other wheels thoroughly, or at least didn't record it if I had.

This is all the relevant data I can think of regarding my usage, but feel free to ask me if you're curious about some other detail!

F14 Wheel Versions

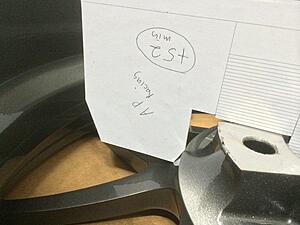

There are apparently two different versions of the 17" F14. This wasn't known to me (or anyone else on S2Ki) until we all started looking more closely at our wheels. I'll refer to them as the thin-spoke and thick-spoke versions.

I've been in contact with Vincent with Forgestar and he has confirmed that the wheel design changed somewhere in 2014. He stated that they were getting complaints that they did not match the other F14 wheels, and they stopped that machining operation.

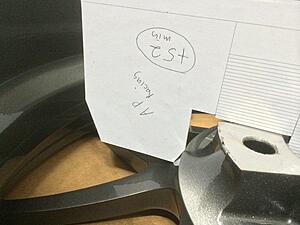

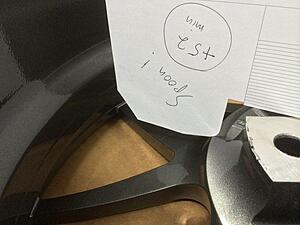

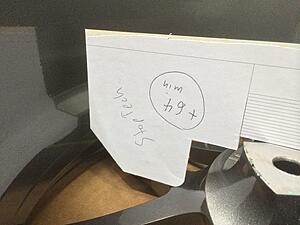

The thin-spoke wheels have spokes that connect at the very edge of the wheel rim, and the spokes are ~19mm. They have a load rating stamp in the center of 1400lbs. My wheels weighed 17.75lbs with powder coat.

The thick-spoke wheels have spokes the connect through the entire wheel rim, and are ~24mm. Their load-rating stamp is 1520lbs. Poster GEARHEAD has thick-spoke wheels, and they weigh 19.25lb.

Here are some pictures showing the differences.

Thin-spoke:

(courtesy King Tut)

(courtesy King Tut)

(courtesy King Tut)

Thick spoke:

(courtesy King Tut)

(courtesy King Tut)

(courtesy King Tut)

Poster King Tut ordered two sets of F14 at the same time, and received one thick-spoke and one thin-spoke version. It's not clear if the distributors are aware there are two different versions. [Update 2014-04-18: It's become clear that the fact there are two versions is unknown some way up the supply chain. Poster King Tut checked all of his wheels--of his gunmetal powdercoated set, 2 are thin, and 2 are thick. Of his gold powdercoated set, three are thin, one is thick.] [Update 2014-04-19: Forgestar is replacing all of King Tut's thin-spoke wheels with thick-spoke versions]

Forgestar is pretty close to me, so I dropped off the remaining wheels and the broken center on 2016-04-15. They're going to take a look at them and see what (if anything) was particularly wrong with them. I'll post another update once that gets completed.

Wheel specs and data. Updates as of 2014-04-16 are marked in bold.

Basics: Forgestar F14, 17x10, +55 offset (I will generalize offset where I can). Thin-spoke version.

Forgestar builds to order, so you can get any offset, and any color powder coat (hence the lead time)

Ordering: Ordered from Modbargains, Jurrian was the rep working with me. Estimated arrival of 5-7 weeks, and the wheels were ready to pick up on week 7.

Can't say enough about Modbargains--they did their part. I recommend ordering through them, Jurrian's email is: jurrian@modbargains.com . He was very helpful and gave me accurate updates. [Jurrian no longer works there!]

Weight: 17.75lb, measured by Modbargains prior to tire mounting Note thick-spoke wheels are heavier

Weight with tires: 44.4lbs - sanity check on Modbargains' measurement, confirms wheel weight!

Lower ball joint clearance, Buddy Club: I had previously clearanced my front balljoints to fit Enkei PF01SS, but there is ample clearance now. It appears no clearancing would be necessary to fit BC balljoints with these wheels. Plenty of room in either direction as well, so any offset will work.

Rear Koni V3 clearance: Plenty of clearance to the reservoir with this offset. The reservoir in fact is within the diameter of the wheel, but just barely. An offset higher than ~+70 well be hugging the reservoir, but there is still ~3mm clearance.

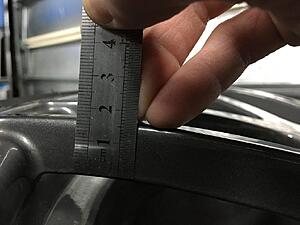

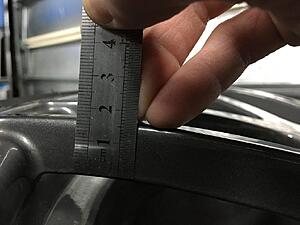

Lugnuts holes: Lugnut holes could be deeper. I can only get 5 rotations before the lugnuts are torqued. I would prefer 8+. Distance between the lugnut face (engaged in with the cone) is 12.3mm, while on my Enkei PF01SS, this distance is 9.2mm.

I calculated out the minimum ISO thread engagement--comes down to 6.5 turns. I'm getting 5. The ISO minimum engagement is the minimum engagement necessary for the bolt to fail before the threads. So likely, the threads will fail first with this few threads. That isn't to say it will fail in use however, but it isn't ideal.

Additionally, pretty heavy powdercoating in the lugnut holes--torque and remove the lugnuts a couple times, blowing out the lugnuts holes in between cycles. The coating will flake off the aluminum until it's all gone and you can get proper torque to the aluminum.

I'm going to use Gorilla "Extended Thread" lug nuts just for piece of mind, instead of going to longer studs or the like. The extended thread section doesn't have the hoop strength of the actual nut part, but there are ~5 more threads engaged. I'm OK with that. These guys: http://www.amazon.com/gp/product/B00...?ie=UTF8&psc=1

I drilled the lugnut holes out slightly to allow the "nose" of the Gorilla Extended Thread nuts to fit inside.

To date, I haven't had any failures, so I guess this works! [well, the lugnuts didn't fail]

Balancing: These seem remarkably well balanced--wheel weights used are as follows:

Outboard weight [oz] / Inboard weight [oz]

1.25 / 0.00

1.00 / 0.50

0.75 / 0.00

1.00 / 0.00

Much better than my Enkeis.

Offset accuracy: Measured to 53mm with tape measure and straightedge. This is close enough that I'm comfortable saying no one fat-fingered the machining center. That being said, I will assume from this point forward that these wheels are +55mm, as ordered from Forgestar (meaning, if I can stick a brake caliper forward 10 more mm, I'll say +65mm will clear). This assumes Forgestar cuts the offsets reasonably accurately.

Minimum offset requirements for brake kits:

Big caveat here! The thick-spoke versions appear to have less brake clearance. These numbers may only apply to the thin-spoke versions.

These offsets are calculated from my wheels, being +55mm. They were tested with templates that included 3mm of clearance.

Essex AP Racing kit (Essex PN# 13.01.10004, AP PN# CP8350 and CP3862): +52mm

StopTech ST40 (PN# 83.435.4300 or similar): +64mm

Spoon: +52mm

Some detail, starting with the AP racing kit:

The angled part of the caliper is almost exactly parallel to the section of the wheel that it interferes with.

Spoon:

This is really strange actually, ending up with the same minimum offset as the AP racing, but whatever. If the caliper stuck out a few more mm, you this could run a pretty high offset, too bad! But +52 is still pretty good...

StopTech ST40:

So this is kinda neat--I think at +64 you could almost get away with not flaring the fenders at all, just rolling the lip. I'd imagine there'd be a good bit of lower control arm interference at full lock though, so you'd probably want to add some steering limiters. I have no idea why you would do this though, because +50-55 looks super badass. Also--the caliper come pretty close to the wheel weights if they're stuck on top of the "ridge" in the wheel. Nothing to really worry about, as you still have a good 6-8mm of clearance.

Longevity:

I've done a lot of track days on RS-3s and R888, and they haven't broken yet. They broke, see above

__________________________________________________ _________________

Original post, prior to receiving my wheels:

As mentioned in a couple other threads in R&C, Forgestar recently starting making 17" wheels in their F14 line--a roll formed cast wheel. This seemed to be an attractive option to me, because they're flexible with offsets, and because they have a more modern design without a large lip, they should be better about clearing big brakes (and to me at least, look a ton better than wheels with lip ). They're also quite cheap--around 1400$ for a set. I ordered a set of +55 from Modbargains.

). They're also quite cheap--around 1400$ for a set. I ordered a set of +55 from Modbargains.

Now, Forgestar has some....history on the internet. There's some dissatisfied customers out there, but it seems that they are largely cosmetic problems (blemishes in the casting, powdercoating problems) and long to ridiculously long lead times. This is just because of how they do business--because they do final machining and powdercoating after the order is placed, it takes a while, if they have blanks available. If they don't have the blanks, they need to be roll-forged in east Asia somewhere and then go on a boat ride. Forgestar's dealers can find out if there are blanks available, and can provide a slightly more accurate lead time.

As for quality--there are some posts on the internet with rims cracking, and out-of-round issues. I didn't find a large numbers of posts about this, and the ones that were out there were old and/or were regarding large diameter wheels. I'll update this thread with further info on my set. If I run into structural integrity issues while on track, my name is Chris and I live in Pasadena if anyone wants to keep an eye on the obituaries. [I didn't die, but still]

I ordered through Modbargains--Jurrian has been helping me and I'm happy with the communication--he's been very helpful and responds to emails in minutes so hey--order from Modbargains I guess. I placed the order on Dec 30, 2013. Jurrian estimated 5-7 weeks, which seemed optimistic, but we're right on schedule, so that's cool. I'll be picking them up this week some time unless something goes wrong.

I'll be measuring these out for BBK clearance (and for interference on my Buddy Club LBJs, and Koni V3s, if anyone is curious there). I currently have templates for the Stop Tech kits and the AP racing kits that Urge is reselling. Post any other templates if you want me to measure them. Spoon maybe? Ive never seen a template for that.

First useful bit of info, they look cool:

Attachment 190536

Second useful bit, they're waaaay lighter than I thought they would be:

Not sure where that falls on the lightweight-racecar/fiery-death spectrum but hey, only one way to find out. [closer to "fiery-death", but not all the way there!]

Left front wheel broke after 14 track days. Fatigue cracking leading to spoke failure. Yikes. Fortunately, the damage to the car was relatively minor, and I got a funny video out of it.

[media]http://www.youtube.com/watch?v=vtYjujhW27Q[/media]

https://www.youtube.com/watch?v=vtYjujhW27Q

Forgestar reached out to me soon after this happened, and offered to refund me the purchase price of the wheels and even paid for the balljoint that got damaged on my slide into the dirt. That was unexpected considering I was using them as dedicated track wheels, and pretty cool of them!

There's been a lot of investigation into this failure by myself and other users, I'll do the best I can to summarize here.

Firstly, and this is the major takeaway from this failure--always inspect any wheel for fatigue cracking, and for that matter, regularly inspect every heavily loaded component on a track/race car. Every aluminum wheel will eventually fail in this manner, although "when" is a very tough question to answer. Wheel manufacturing technique, tire type, track quality, car setup, driving technique, etc, will all effect longevity. Fix some of those variables, and some wheels will last longer than others.

I was surprised that these failed after 14 track days, but these wheels had cracks that were propagating from the backsides of the spokes for some time before they failed. I routinely half-assed my wheel inspections by checking to see if there were any cracks on the outside of the spokes as they were mounted on the car. I wouldn't have had a complete failure on-track had I unmounted the wheels and inspected them thoroughly!

Fatigue Surface

Here are some pictures of the spokes on the failed wheel. The dark section is the result of corrosion of a pre-existing crack. The "fresh" metal is from the total failure. This is the normal appearance of a fatigue crack (on any surface or material). All of the spokes had such fatigue cracks.

Cracked Spokes

Here are some pictures showing the back-side of the spokes on the remaining wheels, these are the type of cracks that you should look for during inspections.

Car Setup and Usage

Seeing as there are a large number of variables that go into the longevity of a wheel, I will do my best to summarize what characterized my usage:

Basics: Wheels lasted 14 track days. Failure at left front. Very minor cracking on right front. Moderate/heavy cracking on both rears.

These wheels were the thin-spoke version of the Forgestar F14, with a 1400lb load-rating stamp. I'll get into the two versions later in this update.

Car basics: ~2800lbs with driver, half tank. Moderate aero--rear wing and splitter.

Suspension: KW v3 (475lb springs), standard ride height. Eibach front and rear swaybars. Buddy club balljoints. Regarding this particular combination-- with KW v3 and Buddy Club ball joints, and adjusting the ride height back to "normal" with the adjusters, results in coil bind PRIOR to bumpstop engagement on the front. I found this out on a particularly hard curb hit that collapsed the spring perch on the right front shock. The KWs use a glass-filled nylon adjuster with a steel reinforcement band. The plastic threads sheared off the adjuster. After this occurred, I added a bumpstop spacer to ensure the bumpstop worked as it should. This is a curious data point, as this wheel was the least cracked of the 4.

Tires: 6 days on R888, 6 days on RS3, 2 days on RE71R, all 255/40-17

Tracks: Buttonwillow and Auto Club, although one day on the RE71R was at Willow Springs.

General driving: this is all very subjective, but I don't baby the car around curbing? I have some videos of my driving here, but it's kind of hard to make sense of how hard I hit curbing-- https://www.youtube.com/user/cgwiita

Offs: I had 5 offs that I would consider "major". They are:

1. BW 13CW, off at Bus Stop, debeaded rear left (tank slapper, slid off track surface to the left) [Update 2014-04-18: wheels were switched left to right after this incident during tire change from R888 to RS3. So this off debeaded what became the rear right]

2. BW 13CCW, overshot Bus Stop (dropped left wheels off the curbing), underbody scraped on the edge of the curbing

3. BW 13CCW, missed braking point on Sweeper, straight 4 off

4. BW 13CW, dropped right front into curbing on inside of Riverside. As mentioned above, this resulted in a sheared adjuster collar as a result of spring coil bind (due to the combination of KW v3 and Buddy Club ball joints).

5. WSIR, missed braking point turn 9, 4 off

I thoroughly inspected the right front after incident #4 as I was sure I had bent or cracked it, and didn't see anything alarming. Curiously, this is the best condition wheel by far, having only very small cracks near the hub on only a few spokes. I most likely didn't inspect the other wheels thoroughly, or at least didn't record it if I had.

This is all the relevant data I can think of regarding my usage, but feel free to ask me if you're curious about some other detail!

F14 Wheel Versions

There are apparently two different versions of the 17" F14. This wasn't known to me (or anyone else on S2Ki) until we all started looking more closely at our wheels. I'll refer to them as the thin-spoke and thick-spoke versions.

I've been in contact with Vincent with Forgestar and he has confirmed that the wheel design changed somewhere in 2014. He stated that they were getting complaints that they did not match the other F14 wheels, and they stopped that machining operation.

The thin-spoke wheels have spokes that connect at the very edge of the wheel rim, and the spokes are ~19mm. They have a load rating stamp in the center of 1400lbs. My wheels weighed 17.75lbs with powder coat.

The thick-spoke wheels have spokes the connect through the entire wheel rim, and are ~24mm. Their load-rating stamp is 1520lbs. Poster GEARHEAD has thick-spoke wheels, and they weigh 19.25lb.

Here are some pictures showing the differences.

Thin-spoke:

(courtesy King Tut)

(courtesy King Tut)

(courtesy King Tut)

Thick spoke:

(courtesy King Tut)

(courtesy King Tut)

(courtesy King Tut)

Poster King Tut ordered two sets of F14 at the same time,

Forgestar is pretty close to me, so I dropped off the remaining wheels and the broken center on 2016-04-15. They're going to take a look at them and see what (if anything) was particularly wrong with them. I'll post another update once that gets completed.

Wheel specs and data. Updates as of 2014-04-16 are marked in bold.

Basics: Forgestar F14, 17x10, +55 offset (I will generalize offset where I can). Thin-spoke version.

Forgestar builds to order, so you can get any offset, and any color powder coat (hence the lead time)

Ordering: Ordered from Modbargains, Jurrian was the rep working with me. Estimated arrival of 5-7 weeks, and the wheels were ready to pick up on week 7.

Can't say enough about Modbargains--they did their part. I recommend ordering through them, Jurrian's email is: jurrian@modbargains.com . He was very helpful and gave me accurate updates. [Jurrian no longer works there!]

Weight: 17.75lb, measured by Modbargains prior to tire mounting Note thick-spoke wheels are heavier

Weight with tires: 44.4lbs - sanity check on Modbargains' measurement, confirms wheel weight!

Lower ball joint clearance, Buddy Club: I had previously clearanced my front balljoints to fit Enkei PF01SS, but there is ample clearance now. It appears no clearancing would be necessary to fit BC balljoints with these wheels. Plenty of room in either direction as well, so any offset will work.

Rear Koni V3 clearance: Plenty of clearance to the reservoir with this offset. The reservoir in fact is within the diameter of the wheel, but just barely. An offset higher than ~+70 well be hugging the reservoir, but there is still ~3mm clearance.

Lugnuts holes: Lugnut holes could be deeper. I can only get 5 rotations before the lugnuts are torqued. I would prefer 8+. Distance between the lugnut face (engaged in with the cone) is 12.3mm, while on my Enkei PF01SS, this distance is 9.2mm.

I calculated out the minimum ISO thread engagement--comes down to 6.5 turns. I'm getting 5. The ISO minimum engagement is the minimum engagement necessary for the bolt to fail before the threads. So likely, the threads will fail first with this few threads. That isn't to say it will fail in use however, but it isn't ideal.

Additionally, pretty heavy powdercoating in the lugnut holes--torque and remove the lugnuts a couple times, blowing out the lugnuts holes in between cycles. The coating will flake off the aluminum until it's all gone and you can get proper torque to the aluminum.

I'm going to use Gorilla "Extended Thread" lug nuts just for piece of mind, instead of going to longer studs or the like. The extended thread section doesn't have the hoop strength of the actual nut part, but there are ~5 more threads engaged. I'm OK with that. These guys: http://www.amazon.com/gp/product/B00...?ie=UTF8&psc=1

I drilled the lugnut holes out slightly to allow the "nose" of the Gorilla Extended Thread nuts to fit inside.

To date, I haven't had any failures, so I guess this works! [well, the lugnuts didn't fail]

Balancing: These seem remarkably well balanced--wheel weights used are as follows:

Outboard weight [oz] / Inboard weight [oz]

1.25 / 0.00

1.00 / 0.50

0.75 / 0.00

1.00 / 0.00

Much better than my Enkeis.

Offset accuracy: Measured to 53mm with tape measure and straightedge. This is close enough that I'm comfortable saying no one fat-fingered the machining center. That being said, I will assume from this point forward that these wheels are +55mm, as ordered from Forgestar (meaning, if I can stick a brake caliper forward 10 more mm, I'll say +65mm will clear). This assumes Forgestar cuts the offsets reasonably accurately.

Minimum offset requirements for brake kits:

Big caveat here! The thick-spoke versions appear to have less brake clearance. These numbers may only apply to the thin-spoke versions.

These offsets are calculated from my wheels, being +55mm. They were tested with templates that included 3mm of clearance.

Essex AP Racing kit (Essex PN# 13.01.10004, AP PN# CP8350 and CP3862): +52mm

StopTech ST40 (PN# 83.435.4300 or similar): +64mm

Spoon: +52mm

Some detail, starting with the AP racing kit:

The angled part of the caliper is almost exactly parallel to the section of the wheel that it interferes with.

Spoon:

This is really strange actually, ending up with the same minimum offset as the AP racing, but whatever. If the caliper stuck out a few more mm, you this could run a pretty high offset, too bad! But +52 is still pretty good...

StopTech ST40:

So this is kinda neat--I think at +64 you could almost get away with not flaring the fenders at all, just rolling the lip. I'd imagine there'd be a good bit of lower control arm interference at full lock though, so you'd probably want to add some steering limiters. I have no idea why you would do this though, because +50-55 looks super badass. Also--the caliper come pretty close to the wheel weights if they're stuck on top of the "ridge" in the wheel. Nothing to really worry about, as you still have a good 6-8mm of clearance.

Longevity:

I've done a lot of track days on RS-3s and R888, and they haven't broken yet. They broke, see above

__________________________________________________ _________________

Original post, prior to receiving my wheels:

As mentioned in a couple other threads in R&C, Forgestar recently starting making 17" wheels in their F14 line--a roll formed cast wheel. This seemed to be an attractive option to me, because they're flexible with offsets, and because they have a more modern design without a large lip, they should be better about clearing big brakes (and to me at least, look a ton better than wheels with lip

). They're also quite cheap--around 1400$ for a set. I ordered a set of +55 from Modbargains.

). They're also quite cheap--around 1400$ for a set. I ordered a set of +55 from Modbargains.Now, Forgestar has some....history on the internet. There's some dissatisfied customers out there, but it seems that they are largely cosmetic problems (blemishes in the casting, powdercoating problems) and long to ridiculously long lead times. This is just because of how they do business--because they do final machining and powdercoating after the order is placed, it takes a while, if they have blanks available. If they don't have the blanks, they need to be roll-forged in east Asia somewhere and then go on a boat ride. Forgestar's dealers can find out if there are blanks available, and can provide a slightly more accurate lead time.

As for quality--there are some posts on the internet with rims cracking, and out-of-round issues. I didn't find a large numbers of posts about this, and the ones that were out there were old and/or were regarding large diameter wheels. I'll update this thread with further info on my set. If I run into structural integrity issues while on track, my name is Chris and I live in Pasadena if anyone wants to keep an eye on the obituaries. [I didn't die, but still]

I ordered through Modbargains--Jurrian has been helping me and I'm happy with the communication--he's been very helpful and responds to emails in minutes so hey--order from Modbargains I guess. I placed the order on Dec 30, 2013. Jurrian estimated 5-7 weeks, which seemed optimistic, but we're right on schedule, so that's cool. I'll be picking them up this week some time unless something goes wrong.

I'll be measuring these out for BBK clearance (and for interference on my Buddy Club LBJs, and Koni V3s, if anyone is curious there). I currently have templates for the Stop Tech kits and the AP racing kits that Urge is reselling. Post any other templates if you want me to measure them. Spoon maybe? Ive never seen a template for that.

First useful bit of info, they look cool:

Attachment 190536

Second useful bit, they're waaaay lighter than I thought they would be:

Not sure where that falls on the lightweight-racecar/fiery-death spectrum but hey, only one way to find out. [closer to "fiery-death", but not all the way there!]

#2

Site Moderator

That's much lighter than I expected especially for a 10 inch wide wheel. Comparatively the TSW Nurburgring are listed on their site as weight 19.2 lbs for the 17x9 so these are 2lbs lighter and an inch wider that is great.

#3

I'm leaning heavily towards ordering a set of these pending BBK clearances. Can you also let us know how smoothly they balance out? From my time in a tire shop I've seen a lot of cheaper wheels have issues even when brand new.

Trending Topics

#8

Thanks for creating this thread. I look forward to your updates!

As you noted, forgestar looks to have had some issues in the past, but it seems like a fair number of cars out there do run their wheels (although you don't hear about them much). They seem to be somewhat popular in the BRZ/FRS crowd. These definitely seem like a nice alternative to the expensive forged wheels out there (as they're prettier and half the cost), but only time will tell.

For those interested in 18's, I think the 5 spoke wheels from forgestar come in a wide range of offsets as well.

As you noted, forgestar looks to have had some issues in the past, but it seems like a fair number of cars out there do run their wheels (although you don't hear about them much). They seem to be somewhat popular in the BRZ/FRS crowd. These definitely seem like a nice alternative to the expensive forged wheels out there (as they're prettier and half the cost), but only time will tell.

For those interested in 18's, I think the 5 spoke wheels from forgestar come in a wide range of offsets as well.