Front Subframe lowering technique for transmission removal?

#1

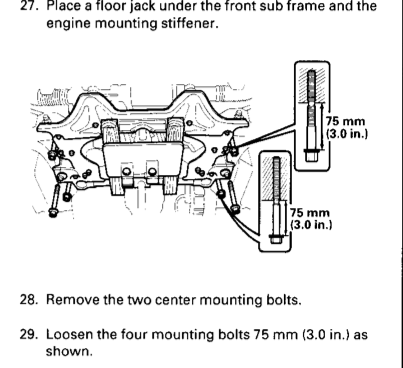

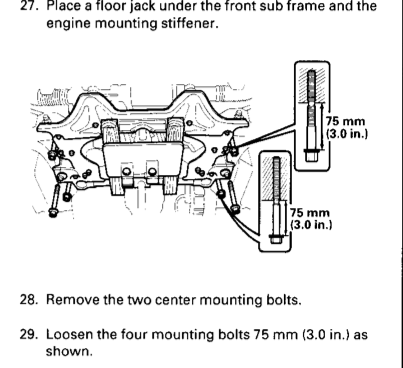

The bolts holding the subframe to the frame will not loosen. I have tried air gun, breaker bar, and socket wrenches. Here is a pic of the instructions. The second picture is of my actual car and bolts..

the left bottom bolt is the bolt that will not budge..

the left bottom bolt is the bolt that will not budge..

#4

I just did mine, used a 4' piece of pipe as a breaker bar and it loosened up easily. My impact wrench didn't budge them even when running at a full 150 psi. If you think these are tough, wait until you get to the top transmission bolt. That one about broke me.

Bill

Bill

#5

^ For top transmission bolt, use 1/2" extensions with your 1/2" drive + breaker bar and won't be a problem.

It's ok to keep the reducer at the end or even an universal joint.

The issue is always too much twist in the smaller extensions.

It's ok to keep the reducer at the end or even an universal joint.

The issue is always too much twist in the smaller extensions.

#6

So there are 3 bolts holding the subframe on each side. Two of them are quite long, and the middle one is shorter. Did you remove the middle one alltogether? I backed the middle one out about 2 inches- still not enough clearance. I don't have a tall enough jack to support the subframe, so I'm afraid of taking the bolt out and having the whole thing drop on me.

#7

The steady torque application of a large bar is not the best way to loosen a long fastener... a more powerful impact gun is ideal. I have found on a really tough large bolt I can up the air pressure from my normal at about 80 to 150 a difficult bolt can be removed without damage.

Trending Topics

#8

I hope you're not trying to remove that bolt with anything less than a 1/2" drive.

#9

penetrating oil will definitely help. It did for me.

I also couldn't get it out with a 200 lb ft impact. returned the impact and bought a 350 lb ft milaukee and it did a little better. still returned it because i wanted to pick up a 800 lbft ingersol. lol

What worked even better is a breaker bar with a 4 foot extension. I used the metal bar used on my hydraulic jack and inserted it into my breaker bar. It came off quite easily.

I also couldn't get it out with a 200 lb ft impact. returned the impact and bought a 350 lb ft milaukee and it did a little better. still returned it because i wanted to pick up a 800 lbft ingersol. lol

What worked even better is a breaker bar with a 4 foot extension. I used the metal bar used on my hydraulic jack and inserted it into my breaker bar. It came off quite easily.

#10

So there are 3 bolts holding the subframe on each side. Two of them are quite long, and the middle one is shorter. Did you remove the middle one alltogether? I backed the middle one out about 2 inches- still not enough clearance. I don't have a tall enough jack to support the subframe, so I'm afraid of taking the bolt out and having the whole thing drop on me.

if there is a harbor freight store near, an you can, go grab a jack that'll reach the sub-frame.. I figure if your going to do the work, get the tools.. cause you'll use them over and over...

remove the middle two bolts completely, seriously, no worries.. the 4 corner bolts are long enough to be lowered the 3 inch drop they claim easy... and measure, don't be " about "

Thread

Thread Starter

Forum

Replies

Last Post