F20C2 Thrust Washers and Excessive Crankshaft End-Float

#12

Now if the crank faces are worn , scored or both can they not be refaced , possibly built up again to the OEM limits for new OEM bearings or possibly finished under OEM size and new over size bearing purchased or made ? Some one some where must be able to do this ? An engine builders and machinist can surely build up the surfaces ( for the life of me can’t remeber the name of the process , similar to spark erosion in reverse ) then machine back to correct dims for OEM bearings?

If as as you say the crank bearing surfaces are good why would you suspect the current bearings and the measurements taken will rapidly wear to a point in excess of service limits again ? did you or they measure the distance between the bearing surfaces on the crank ? Was this dimension as it should be ? The other thought is did Honda have a duff batch of underside bearings which caused the problem in the first instance ? As I recall the tolerances for this are quite course and not particularly tight.

The other thought i keep having is around the longitudinal loads imposed on the crank by the clutch etc does this have something to do with the accelerated wear ? Was something shoving the crank hard one way, did the bearings have one showing significant wear and one not ? This would support my theory and explain the rapidly increasing crank float.

Not really looked but there must be some where to locate a DTI stand or mag base on the block , or even bolt or clamp on a bit of steel plate for it to stick on to allow accurate measurements to be achieved engine in.

If as as you say the crank bearing surfaces are good why would you suspect the current bearings and the measurements taken will rapidly wear to a point in excess of service limits again ? did you or they measure the distance between the bearing surfaces on the crank ? Was this dimension as it should be ? The other thought is did Honda have a duff batch of underside bearings which caused the problem in the first instance ? As I recall the tolerances for this are quite course and not particularly tight.

The other thought i keep having is around the longitudinal loads imposed on the crank by the clutch etc does this have something to do with the accelerated wear ? Was something shoving the crank hard one way, did the bearings have one showing significant wear and one not ? This would support my theory and explain the rapidly increasing crank float.

Not really looked but there must be some where to locate a DTI stand or mag base on the block , or even bolt or clamp on a bit of steel plate for it to stick on to allow accurate measurements to be achieved engine in.

Hi Rob,

Thanks for your input - you may remember it was me who came round to look at Toby's engine when it was half-way through the build to try and understand if mine could be fixed in car and to take some measurements from the block.

So, in order to answer your questions:

The fact one bearing is considerably more worn than the other is not a surprise to me, in fact it is what I expected. After all, the "front" bearing carries all the longitudinal thrust loads when the clutch is pressed, but there is no equivalent load in the other direction to wear the "rear" thrust washer. It is easy to see this in action, pull the crank pulley forward with your hand (obviously when the engine's not running, otherwise it will hurt) then watch as the clutch is pressed. It moves rearwards, but does not return forward when the clutch is released. American S2000s have a clutch interlock so you can't start the car without the clutch pressed. Starting the engine with the crank pushed hard against the thrust washer with, by definition, no oil pressure sounds like a truly bad idea, although they are only splash lubricated anyway.

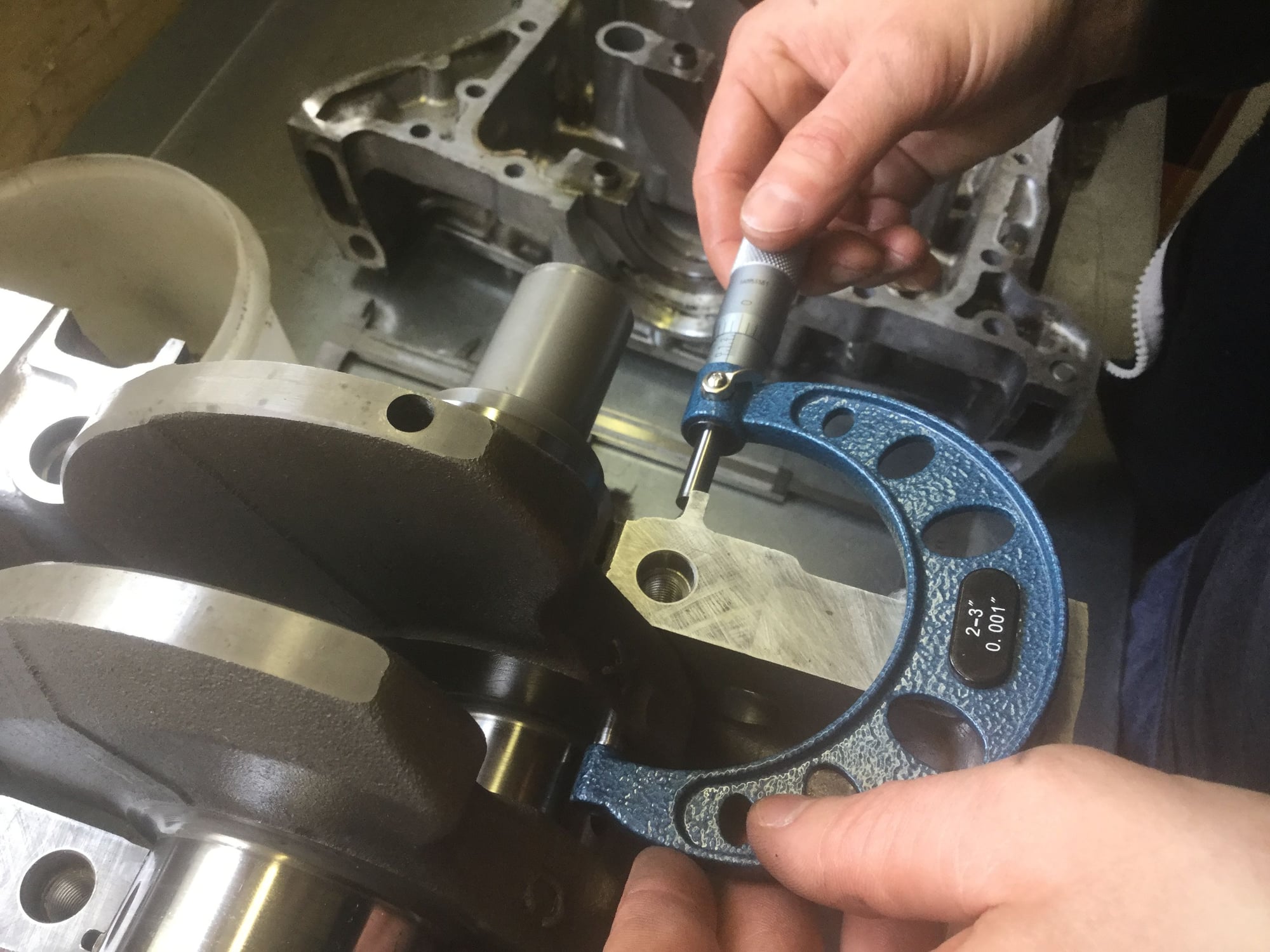

Also, I was measuring the end-float with the magnetic base on the crank pulley itself, and the DTI plunger was facing backwards to touch against a bolt head on the timing cover to measure end float, but as you say you could fix a steel plate to the front of the engine for the magnetic base and then measure directly on the crank pulley bolt which would be an ideal solution. Either way, the important bit is not to mount the DTI on anything except the engine. Mounting on the bodywork and trying to measure the end-float will include a +/- error if the engine mounts move (which of course they do - that's the idea!)

So, thanks to everyone for their input, it's much appreciated. I'll post up periodically with any update on end-float changes with increasing mileage.

Last edited by ValveBounce; 04-18-2021 at 05:41 AM.

#13

I would imagine that the issue you'll have with the thrust bearing face on the crank is whether it is flat and parallel to the thrust washer.

Fingers crossed for you that it is.

Fingers crossed for you that it is.

#14

Yes, I expect you’re right.

If they’re not parallel now, they soon will be (and hopefully still in tolerance)

Last edited by ValveBounce; 04-18-2021 at 05:42 AM.

#15

Ah ah , valve bounce , yes I remember , long time ago and much water under the bridge.

lower, yes that would all have an influance on the life of the bearings if some pathing was odd about the crank bearing faces or indeed the bearing housing in the block.

lower, yes that would all have an influance on the life of the bearings if some pathing was odd about the crank bearing faces or indeed the bearing housing in the block.

Thread

Thread Starter

Forum

Replies

Last Post