Supercharger Flutter

#42

Originally Posted by johnckeen

mine is not like that, it just makes a constant woosh which gets quieter...

I'll see if i can get a video together tonight

I'll see if i can get a video together tonight

#43

The fluttering noise is actually the compressed air from the supercharger rebounding off the closed throttle butterfly, back into the supercharger and is the noise of the compressor being forced into "chopping" this back flow of air. Too much will actually cause the supercharger to stall (the engine is driving it one way and the back flow of air is effectively trying to stop it from spinning), which could actually snap the compressor wheel. HOWEVER, it would have to be a LOT of air flow to do this.

There are two schools of thought, but it mainly depends on how much airflow is being reversed. The first school of thought is that a small amount of backflow is not harmful and will actually aid response and reduce lag (as the intake is still partially pre-charged with air, so there will be no delay when getting back on the throttle). In my Cosworth days, we did not run any kind of blow-off / dump valve for this exact reason on any turbo smaller than a T4 (go on You Tube and search for any Cosworth rally car and you will hear "proper" turbo-stall (AKA "flutter / chatter"). The other school of thought is that all flutter (stall) is bad and should be removed, which requires a totally efficient blow-off arrangement. Be aware that this may create lag though (the time it takes for the boost to built back to what-ever the peak is at that rpm, once WOT has been applied - not to be confused with boost threshold).

It may be that the HKS blow-off valve is designed to just release enough pressure to prevent damaging stall, but still keep sufficient charge in the intake system to keep lag to a minimum. Obviously they will confirm this, but if some are getting it and some aren't, it might suggest that the point the blow-off valve is connected (where those are getting "flutter") is not a good enough vacuum to fully operate the blow-off valve. If you have a means to block off the BOV connection point, then you can remove it to check it is operating properly, If the noise does not change, then the BOV is not operating as it should. If the fluuter noise gets louder / more frequent, then the BOV is at least doing something.

Hopefully HKS will confirm how their set up is. On my Cosworth, which was running 32psi from a T4 (which absolutely had to have a BOV due to the 47lb of air a minute this turbo could move), I had the smallest one I could which only had a 20mm ID port. This meant that it vented enough pressure to prevent full blown compressor stall (thus protecting the turbo), but still kept sufficient charge in the intake to aid throttle response. So I got booth noises (the whoosh of the BOV dumping and the flutter of the turbo "stalling".

Obviously the principle is the same, as a supercharger is just a crank driven "turbo". If you're running below 1 bar (14.7psi), then I would be surprised if it caused any damage (but does depend on the strength / build quality of the charger).

There are two schools of thought, but it mainly depends on how much airflow is being reversed. The first school of thought is that a small amount of backflow is not harmful and will actually aid response and reduce lag (as the intake is still partially pre-charged with air, so there will be no delay when getting back on the throttle). In my Cosworth days, we did not run any kind of blow-off / dump valve for this exact reason on any turbo smaller than a T4 (go on You Tube and search for any Cosworth rally car and you will hear "proper" turbo-stall (AKA "flutter / chatter"). The other school of thought is that all flutter (stall) is bad and should be removed, which requires a totally efficient blow-off arrangement. Be aware that this may create lag though (the time it takes for the boost to built back to what-ever the peak is at that rpm, once WOT has been applied - not to be confused with boost threshold).

It may be that the HKS blow-off valve is designed to just release enough pressure to prevent damaging stall, but still keep sufficient charge in the intake system to keep lag to a minimum. Obviously they will confirm this, but if some are getting it and some aren't, it might suggest that the point the blow-off valve is connected (where those are getting "flutter") is not a good enough vacuum to fully operate the blow-off valve. If you have a means to block off the BOV connection point, then you can remove it to check it is operating properly, If the noise does not change, then the BOV is not operating as it should. If the fluuter noise gets louder / more frequent, then the BOV is at least doing something.

Hopefully HKS will confirm how their set up is. On my Cosworth, which was running 32psi from a T4 (which absolutely had to have a BOV due to the 47lb of air a minute this turbo could move), I had the smallest one I could which only had a 20mm ID port. This meant that it vented enough pressure to prevent full blown compressor stall (thus protecting the turbo), but still kept sufficient charge in the intake to aid throttle response. So I got booth noises (the whoosh of the BOV dumping and the flutter of the turbo "stalling".

Obviously the principle is the same, as a supercharger is just a crank driven "turbo". If you're running below 1 bar (14.7psi), then I would be surprised if it caused any damage (but does depend on the strength / build quality of the charger).

The following users liked this post:

CynicG (01-10-2017)

#45

Thread Starter

My worry is that not everyone's car is reacting in the same way. (Assuming everyone's running the kits as HKS sent them out)

#46

The only way other cars "could" be running differently (as in making different noises) on the "same" kit is:

1. The BOVs are sprung differently.

2. The vacuum take-off point being utilised from car to car is different (meaning insufficient vacuum to fully operate the BOV).

3. People are running different boost pressures (the more boost, the louder the flutter). Don't forget that as the supercharger is engine driven, it will be making more boost at 9k than at 8k, so the flutter noise will be much louder the higher the rpm (because that equals more boost).

1. The BOVs are sprung differently.

2. The vacuum take-off point being utilised from car to car is different (meaning insufficient vacuum to fully operate the BOV).

3. People are running different boost pressures (the more boost, the louder the flutter). Don't forget that as the supercharger is engine driven, it will be making more boost at 9k than at 8k, so the flutter noise will be much louder the higher the rpm (because that equals more boost).

Last edited by Mike RT4; 01-10-2017 at 01:16 AM.

#47

So I'd start with the below:

Remove the hose that runs back from the BOV to the intake track to see if that helps

If not, check vac lines. If all is ok then I'd run a direct vac line from the intake manifold to see if a dedicated vac helps.

If not, I'd remove the BOV and inspect.

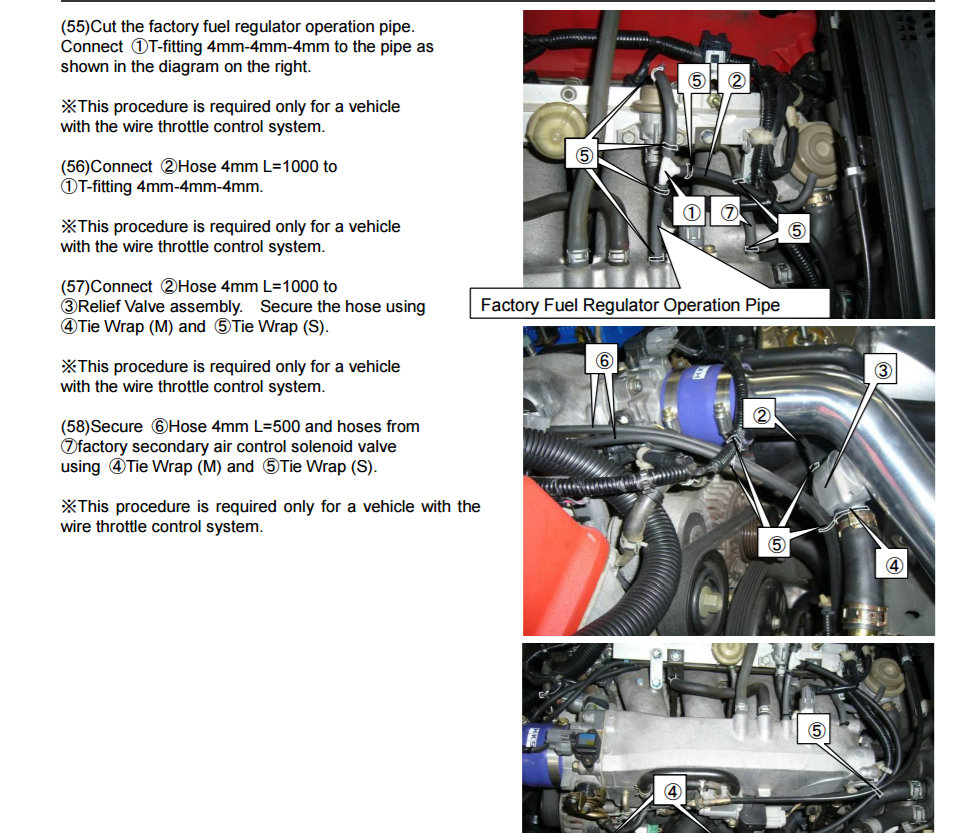

Could someone post the instructions supplied by HKS to see how they instructon to plumb in the BOV?.

Also, is there any markings on the BOV to show at what pressure the spring operates?

Last edited by E4RTH WORM JIM; 01-10-2017 at 02:58 AM.

#49

Thats how mine is setup.

i did use some samco hose i bought though not the supplied as it seemed too soft and prone to possible collapse.

Maybe some peoples are pinching under vacuum?

i did use some samco hose i bought though not the supplied as it seemed too soft and prone to possible collapse.

Maybe some peoples are pinching under vacuum?

#50

Thread Starter

What Size hose did you use? do you have a link. Id be happy to buy some and try it out as that seems to be a fairly simple fix.