Shop to Re-Valve KW V3?

#92

Former Moderator

Thread Starter

TWF does this look right?

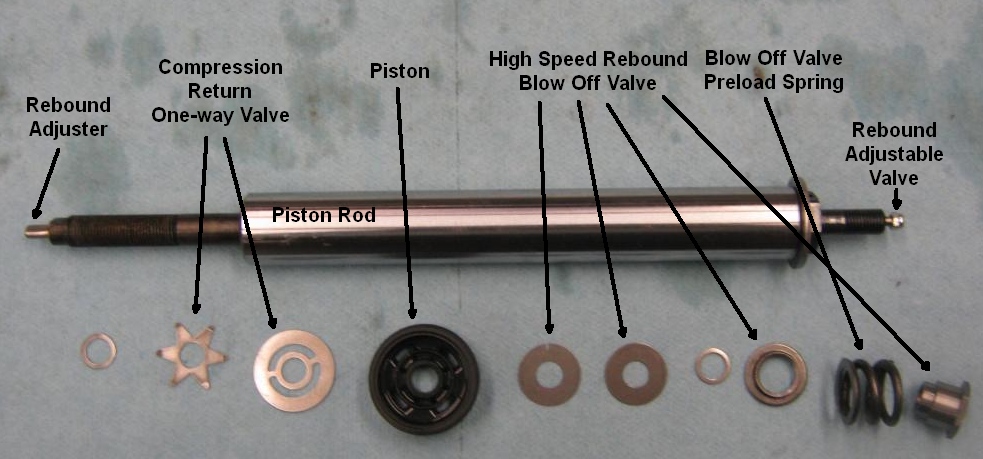

Like I said, if we can stiffen up the moderate and high speed rebound compression by about 30% I'll be happy. Maybe just adding preload to the blow off valve spring could do it? I'm perfectly happy with the high and low speed compression valving.

Like I said, if we can stiffen up the moderate and high speed rebound compression by about 30% I'll be happy. Maybe just adding preload to the blow off valve spring could do it? I'm perfectly happy with the high and low speed compression valving.

#94

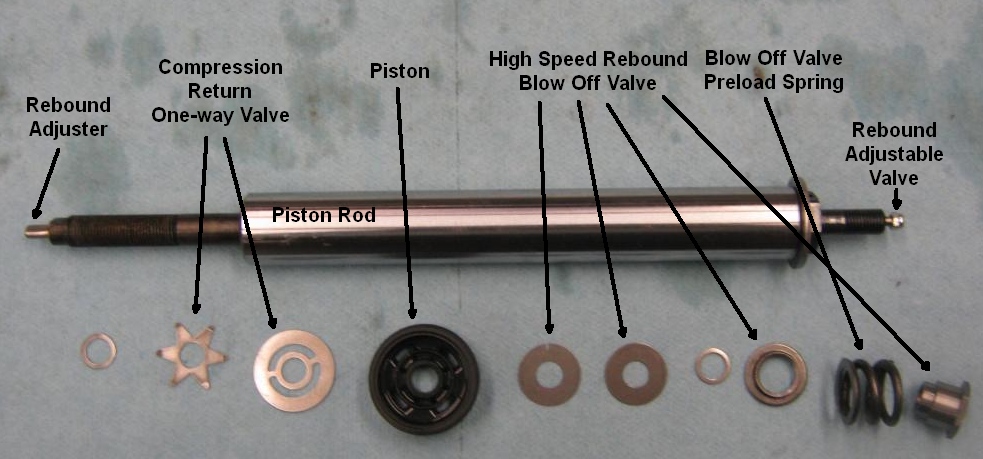

What is marked compression shim stack is basically refill, when shaft is in compression stroke oil has to pass through behind the valve and refill chamber with oil. That star looking washer is spring washer. When shaft goes up on rebound stroke that washer is check valve, it closes ports and oil flows through needle and when enough pressure through rebound shim stack. Except that is not really shim stack, just washer closing ports and spring loaded. In real shim stack washers bend to let oil through, here it lifts, bends around small one but lifting spring. First washer there has small notch which is bleed. On different shocks you would have little pin hole drilled in valve itself for bleed.

Your rebound works through that spring you see 2nd from right on picture. To the right of spring is screw/hat that threads on that shaft above and puts preload on spring. It bottoms out on those washers, little one and other 2 and clamps everything together. On left side of that spring is just bottom hat. It keeps spring centered and sits on top of those two bigger washers. If you look at screw it has step on it. That step fits inside bottom hat, so does little shim. When assembled bottom hat is about 1mm from step on screw. Pressure will compress that spring but only up to that step. Basically you have 1mm of travel on spring. That is your rebound damping.

Your rebound works through that spring you see 2nd from right on picture. To the right of spring is screw/hat that threads on that shaft above and puts preload on spring. It bottoms out on those washers, little one and other 2 and clamps everything together. On left side of that spring is just bottom hat. It keeps spring centered and sits on top of those two bigger washers. If you look at screw it has step on it. That step fits inside bottom hat, so does little shim. When assembled bottom hat is about 1mm from step on screw. Pressure will compress that spring but only up to that step. Basically you have 1mm of travel on spring. That is your rebound damping.

#95

Former Moderator

Thread Starter

Thanks for the explanation and clarification TWF. Did any of the parts look warn out or are there any issues that would prevent a rebuild? I know I didn't see any oil leaks when I pulled the shock.

#96

Like I said, if we can stiffen up the moderate and high speed rebound compression by about 30% I'll be happy. Maybe just adding preload to the blow off valve spring and stiffening up the "rebound shim stack" could do it? I'm perfectly happy with the high and low speed compression valving.

Got few things to measure and figure before deciding what to do.

#97

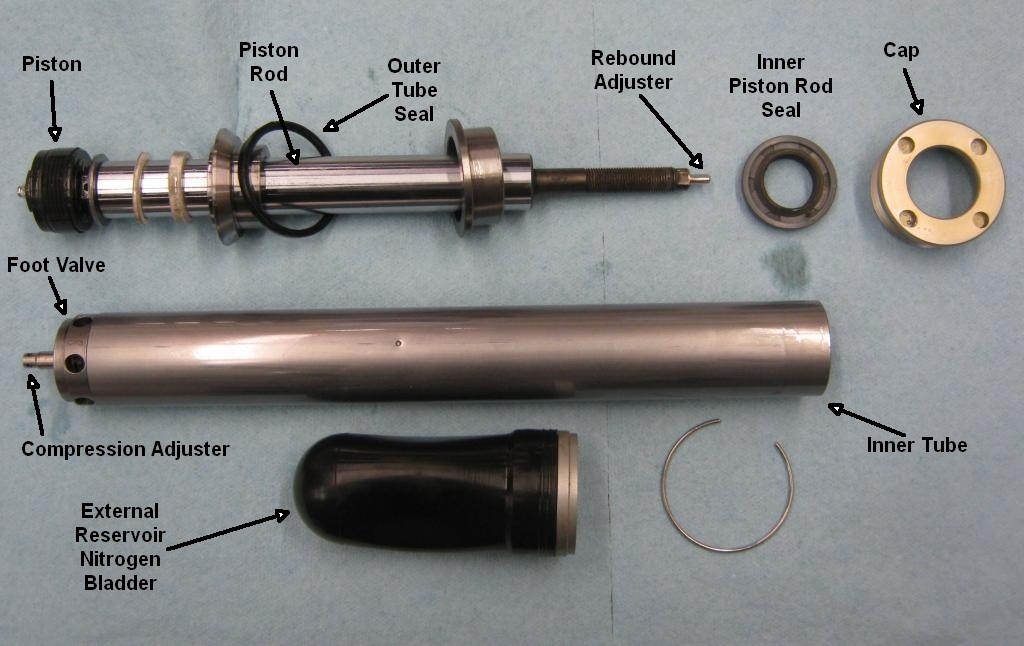

It would be nice to source inner piston rod seal and replace those since already apart.

#98

Former Moderator

Thread Starter

TWF, Why don't you give KW USA (800-445-3767) a call and see if they'll sell you 4 of the inner piston rod seals (of course I'll cover the cost). Since you're a racing shop maybe they'll do it. If you do call don't mention anything about revalving, just rebuilding

Oh, and thank you very much for tearing the shock apart on a Saturday during "Bowl Week." Seriously, thanks for the quick tear down and initial report.

Oh, and thank you very much for tearing the shock apart on a Saturday during "Bowl Week." Seriously, thanks for the quick tear down and initial report.