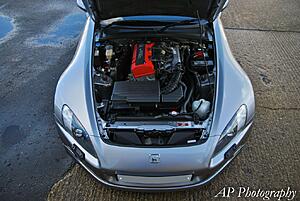

My 1999 Honda s2000 Project

#21

Registered User

Thread Starter

Task 25 - Radiator Fans Constantly On

27-08-2018

From the past couple weeks, it had been noticed that the radiator and A/C radiator fans turn on immediately after pre ignition, engine start and on a cold engine. The engine temperature would be ok and no overheating was present.

The radiator fan should only switch on when the coolant reaches a certain temperature, I think around 93-95 degrees. I set about to find out what was wrong.

Thanks to a few old s2ki forum threads, I performed a few tests to find a root cause to the problem.

The threads pin pointed the radiator fan switch to be the most likely problem.

I performed a few tests to confirm this:

-Swapped over the radiator fan switch relay (there is an identical relay within the fuse box)

Result: No difference

-Disconnect the radiator fan switch itself

(fan switch is located on the left hand bottom section of the radiator)

Result: On pre-ignition, engine start and cold engine, the radiator fans do not switch on.

With the above findings it concluded that the existing radiator fan switch is stuck in the closed position.

I am all for sourcing and using genuine Honda parts but for something quite relatively easy to change, several members have recommended a good after market brand.

The Honda OEM part, cheapest I found was £67.00 (Usual RRP £94.00)

After market type: £13.00

The brand of the aftermarket type was Canbiare which is a well known European brand.

I decided to go for this one.

The switch was relatively easy to access, and from several threads it required no coolant bleeding when swapping it out within the radiator which was a plus point.

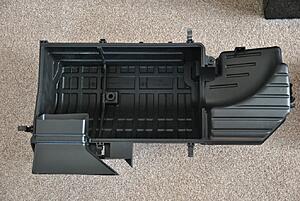

The lower under tray was a tad tricky to remove with most of its clips crumbling upon removal.

It would seem that it had never been removed.

With the under tray removed, a good general clean was also performed.

The radiator fan switch has a size 24mm hex and a deep socket was required to remove it.

I realised this quite late and didn't have one in the tool box.

A trip to Halfords solved this.

Just a little spillage of coolant during the quick swap over and that was it.

The radiator fan switch is located at the bottom of the radiator when the red arrow is pointing.

Upon engine start and warm-up the fans kicked in as normal and switched off as expected.

A long 40 min drive confirmed full function had been restored.

The old radiator fan switch removed

Parts Purchased:

Part: Radiator Fan Switch

Honda Part Number: 37760-P00003

Canbiare Part Number: VE709047

Supplier: Car Parts In Motion (Ebay Seller)

Tool: 24mm Deep 1/2 inch Socket

Supplier: Halfords

https://www.halfords.com/workshop-to...24mm-1-2-drive

Services Used:

None

Resources used

S2ki Thread: Fans Always on

https://www.s2ki.com/forums/uk-irela...lways-1131621/

Thread I Started

https://www.s2ki.com/forums/uk-irela...arket-1187554/

--------------------------------------------------------------------------------------------------------------------------

TASK 26 - Remove Rear Bumper & Lights (Clean and Under Seal)

28-08-2018

The next task on the agenda was to remove the rear bumper, this would give the opportunity to have a peek behind and see the condition of the rear beam and chassis area.

The bumper removal was pretty straight forward and with the process fairly common with most Honda's. Two screws on either side into the rear quarter, clips on top of the rear bumper, three clips on the bottom section of the rear bumper and two clips either side of the arch.

Once the bumper was off the condition of the rear beam and chassis sections weren't too bad. Few light rust spots with the rear beam rusty in a few places. From research, it seems the rear beam is common to rust due to its location and having no protection from any stone chips.

All sections were cleaned and the wire brush came out, light rust spots were brushed with the rear beam also being tidied up the best it could.

Hammerite rust remover was applied on required areas and then followed a coat of dinitrol under seal spray.

A general clean and wipe down was given to all other areas.

Rear number plate bulbs were replaced and terminals greased up to prevent corrosion

The rear lights were removed inspected and cleaned.

All sections behind the lights were in great condition with no leaks or rust.

The connectors were checked and no signs of corrosion was present.

No moisture or leaks were present behind the boot trim.

The light cluster gaskets were checked and cleaned.

The rear bumper was re-installed and new clips were used in all locations.

Parts Purchased:

Part: Dinitrol Under seal Spray 500ml x3

Part Number: 4941

Supplier: MTS Trading (on ebay)

Part: Hammerite rust remover (gel)

Part Number: 5092868

Supplier: Halfords

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

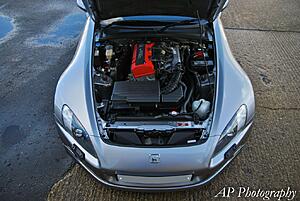

TASK 26 - Remove Front Bumper (Clean and Rust Treat as Required)

02-09-2018

It made sense that the next task was to perform a front bumper removal.

This would also be an opportunity to check for any rust or damage within this area.

Again, the front bumper removal is similar to all Honda's, two screws either side of the front arch, several bolts on the top section of the bumper, two hidden 10mm bolts either side facing the headlamps and several bolts on the underside of the bumper.

Both front arch liners were also removed to aid in access.

Once the bumper was carefully removed the condition of the front sections of the car were also in pretty good condition, with a few rust spots on the front cross beam and various brackets as one would expect.

The rust spots were rubbed down and Hammerite rust remover was applied, followed by a quick coat of touch up paint.

An overall wipe down of all areas were performed and it was looking really fresh.

The air pump was checked and seemed in good clean condition, the previous owner had not tempered with it.

It is common for owners to delete this component if it fails, as it is in good working condition it will be left alone.

The air pump is designed to blow air into the exhaust system upon a cold engine start to quickly heat up the catalytic converter and thus reduce emissions from cold starting.

If you're air pump has failed, you would get a MIL (malfunction indicator lamp) appear on your dash cluster.

If your fault code has detected that the air pump has failed, you can delete it with a special kit from a company called "Delta Lima"

There will be no operating issues, only slightly higher emissions when the car is started from cold.

This will not affect your MOT as the car will be fully warmed and up to operating temperatures when emissions are tested.

The kit has been proven by many s2000 members on this forum.

The bumper itself was checked for damage and also cleaned.

The front number plate and holder were examined, all bolts mounting the holder were clean and not seized.

Due to some cosmetic damage to the number plate holder and number plate itself, I will be replacing both these items later on so it was good to see it will be hassle free.

Parts Purchased:

Part: Hammerite rust remover (gel)

Part Number: 5092868

Supplier: Halfords

Services Used:

None

Resources used

None

If required - Air Pump Delete Kit from Deltalima

https://www.s2ki.com/forums/european...e-kit-1139689/

EGR-Airpump delete (English) – Deltalima-S2000.nl

------------------------------------------------------------------------------------------------------------------------

Task 27 - Rear Mid Level Spoiler

07-09-2018

The s2000 does look fantastic as standard, but I have always loved the look of the mid level spoiler that comes on a few models. This spoiler is an upgrade accessory and apparently still available from Honda, the only issue with the genuine part is that it is quite expensive and requires holes to be drilled within the boot lid to attach it which I refuse to do.

After a search on the forum, there is an aftermarket cheaper and easy to fit solution.

A highly recommended seller which goes by the name of "BMWchop" (a seller on eBay)

From reviews and feedback from many threads on s2k UK, the shape of the spoiler, quality and paint match is amazing.

Many members have reported nothing but good things and from all the images posted up it looks and fits fantastic.

I was convinced by this so had to try it for myself, an order was placed for NH630 pre-painted version and with a handy 10% eBay voucher at the time it worked out even cheaper.

The seller was very efficient with it arriving in just two days and no import duty charge! Great result.

He spoke good English and kept me up to date.

Arrival of the spoiler

Once arrived, a test fit was performed. The colour match was fantastic and the fitment was excellent.

Very impressed indeed, given its price.

On fitment I tried the supplied double sided adhesive tape, but I didn't feel confident that it would stick well despite various reports from other members that it was fine.

I decided to purchase some 3M automotive Vey High Bond adhesive.

I purchased the longer thinner strip (1.5mm thick tape 3M Automotive very High bond Adhesive) for the top and bottom edges of the spoiler.

https://www.ebay.co.uk/itm/3M-VHB-Do...53.m2749.l2649

For the spoiler end sections I used slightly thicker (2.3mm 3M Automotive very High bond Adhesive)

(These came in a small square 100mm x 50mm size which I cut up into two strips of 50mm x 25mm and positioned them either side of the spoiler.

https://www.ebay.co.uk/itm/3M-VHB-10...53.m2749.l2649

The reason why I went for a slightly thicker tape on the end sections is the recess is slightly deeper where the spoiler curves into the ends of the boot edge.

The underside of the spoiler was sanded down to provide an abraded surface for the double sided adhesive to adhere well too.

Once all the tapes was positioned on the spoiler, I got to work to fit it.

The boot lid surface was cleaned with fairy liquid to ensure a clean grease free surface.

I didn't have any masking tape so I just used what I had in my tool box.

Electrical tape was used to provide me with a guide for fitment as this would be a onetime action.

Once suitably aligned within the position marked, the self adhesive backing was removed and the spoiler was pressed into position.

Attachment 152447

The bond of the tape is fantastic, It definitely gives that confidence of a good adhesion to the boot lid.

The spoiler looks fantastic and definitely gives the s2000 a much sportier look.

Extremely happy with the look, quality and results, highly recommended.

Attachment 152448

Parts Purchased

Part: s2000 Mid Level Spoiler

Part Number: N/A

Supplier: BMWchop (on ebay)

Part: 3M Automotive Very High Bond Double Sided Tape (Reel) (1.5mm Thick)

Part Number: RP62

Supplier: fasttapes (on ebay)

Part: 3M Automotive Very High Bond Double Sided Tape (2.3mm Thick)

Part Number: 3M VHB 4991

Supplier: happy-london-tapes (on ebay)

Services Used:

None

Resources used

S2k Thread - Spoiler Recommendation

https://www.s2ki.com/forums/uk-irela...dvice-1103781/

S2k Thread - Adhesive tape for Spoiler

https://www.s2ki.com/forums/uk-irela...kness-1187765/

------------------------------------------------------------------------------------------------------------------------

Task 28 - Genuine Front Pre-Face Bumper Lip

07-09-2018

I've always loved the look of the pre facelift s2000 with a front lip as it added a subtle aggression to the s2000 without going over the top.

I had an urge to source one but wasn't sure if they were still available.

After several enquiries it became apparent that Honda still had stock of them and they were available in my pre painted Silverstone metallic colour

Fantastic result.

Unfortunately, the price of this part had increased dramatically over the years and I had to decide whether or not it was worth to pay such a price for one.

I tried to search for alternatives just like with the mid level spoiler.

There were replica's available but from reviews/feedback, the fitment is not great and unless you have a body shop to hand to help fit, paint and attach it, alot of people say to avoid them as the costs and hassle involved isn't worth it.

The genuine part comes pre-painted and attaches as any genuine part does. Utilising existing mounting points with the supplied hardware it takes on average 20mins to fit and the fitment should be perfect.

I contemplated long and hard about it, and thought what the hell. This would most likely be my last upgrade to the car.

Let's go for it.

I placed an order and within 3 days it arrived. The paint finish and quality is as you would expect from a genuine part, flawless. I was glad a genuine part was purchased.

The box was huge!

Fitting the lip was straight forward, with the supplied instructions it just needed the removal of the three centre bolts from the underside of the bumper and a couple of pilot holes drilled on either side of the bumper edges for self tapping screws for the front lip end attachment.

A further 2 bolts per side on the underside were required with the supplied fastening bolts.

A hint of copper grease was used on all bolts and screws for easy removal in the future.

The lip wrapped around the bumper perfectly like a glove and with all the bolts securing it, installation was complete within 30mins and that was me taking my time including adding a layer of wax behind the bumper section that will be covered by the lip.

Fantastic transformation, the front lip does really look good on the pre-face lift s2000.

Fully installed

A great buy and highly recommended to any pre-face lift owner.

Parts Purchased

Part: Genuine Front Under Lip (pre painted in Silverstone metallic)

Part Number: 08F01-S2A-681F

Supplier: Coxmotorparts

Services Used:

None

Resources used

Supplied Instruction Manual for Front Lip Fitting

Also can be found online here

https://www.handa-accessories.com/S2000/s2kfuspoil.pdf

------------------------------------------------------------------------------------------------------------------------

TASK 29 - Investigate Water Leak into Driver Footwell - (PROBLEM 2)

10-09-2018

In the early months of my s2000 ownership, it was noticed that a small water leak was apparent.

This was resolved my repairing the rubber seal on the A-pillar which now re-directs the water as it should out into the door channel recesses.

After a few more heavy rainfalls it was noticed that a slight trickle of water was still entering the cabin and making the carpet underneath the drivers pedals slightly wet. The water seemed to also be absorbed up within the insulation in this area underneath the main floor carpet.

The previous owner never really suffered from this as the car was stored under a car port.

This was on the agenda and was vital I resolve this before winter approaches.

Even getting additional help from a garage to completely strip the interior to find the root cause if required .

I set aside a full day of diagnosis and went about eliminating various sections just to make sure I covered all areas.

Not having any access to a hose pipe or running water I relied on my battery powered portable jet washer to simulate rainfall. Known as the Mobi V17, other similar models are known and manufactured by Sealey or Aqua2go if interested.

Fantastic bit of kit, stores around 18 litres of water and provides excellent suitable pressure.

I checked all the seals around the windows and roof. Moving towards the front and around the A-pillars.

This included all drain points in the engine bay and the drain point under the windscreen wiper cowling

I double checked and removed all the A-pillar plastic mouldings.

No sign of any water entering.

The rear roof drains were checked and confirmed water was draining fine in this section.

The next stage was to remove the wind screen wiper cowling section.

(this will also be documented separately on the next task for inspection and clean)

With the cowling removed, the wind screen seal was inspected with no defects apparent.

The windscreen is still the original Honda part which gave a good sigh of relief it had not be tampered with or previously replaced.

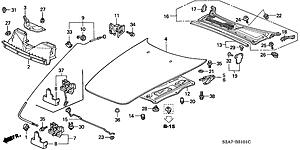

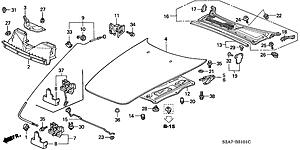

Back into the driver's footwell, I removed the x2 bolts holding the foot rest and the lower right side panel which sits over the bonnet release catch (the driver's door side sill) needs to be unclipped and removed first.

In this state, water can be sprayed and hopefully monitor its point of entrance.

Water drain points are located in the upper corner of the drivers engine bay and another one under the bonnet hinge area.

I used my battery powered pressure washer to direct water at these drain points whilst monitoring.

To my amazement, the water was found trickling into the cabin very slowly. The area where it entered was to the right hand side where the bonnet release cable exits the cabin.

There seemed to be a missing seal or grommet surrounding this cable, a brief look later through the receipts proved that the bonnet release cable was replaced in 2009 and the garage who replaced it did not re-fit the grommet seal.

Item 10 required

The part is still readily available from Honda and only around £4.54.

An order was replaced with a very quick lead time of a few days.

Once the part arrived the fitting was straight forward, the carpets were given a good scrubbing with autoglym shampoo. All underlay sections of the carpet was ensured fully dry using my hobby heat gun.

Some copper grease (all I had at the time)was used on the cable and grommet to allow the grommet to feed itself easily through the cable. It was quite tricky but with alittle patients the grommet secured itself nicely within the aperture sealing it perfectly.

Grommet installed

The end clip to hold the bonnet release plastic panel in place was also purchased as this was original missing when the car was purchased.

All components fully reassembled

Hopefully this saga can now be put to rest.

A fantastic result, I couldn't have asked for a better outcome

Parts Purchased

Part: Grommet Seal for Bonnet Release Cable

Part Number: 74134-SM-4000

Supplier: Coxmotorparts

Part: 7mm Clip to Secure Side Panel

Part Number: 90667-S0D-003ZH

Supplier: Coxmotorparts

Services Used:

None

Resources used

My Mobi V17 Portable Pressure Washer.

Now known as Aqua2go.

https://www.aqua2go.eu/en/overview.html

--------------------------------------------------------------------------------------------------------------------------

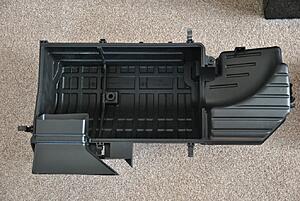

TASK 30 - Remove Windscreen Wiper Cowling (Inspect and Clean)

09-09-2018

During the above investigation and after it was solved, it made sense to also inspect and clean this area of the car. With the cowling assumed not having been removed throughout the car's lifetime it definitely showed.

Cobwebs, debris and leaves were everywhere and as expected.

A quick hose down using the portable jet washer removed most of the dirt

(Special care was taken not to soak or get the cabin filter wet)

With the cowling removed, the filter panel and the fan housing down into the heater matrix was fully inspected and checked.

Additional wiping down of various sections continued the clean.

All fittings and cables were inspected with no evidence of any tampering or modifications.

Small surface rust was rubbed down and treated on the centre clip section.

A slight hint of copper grease was used on the wiper motor attachments so the wiper arms do not seize up in the future. (they were quite tricky to remove initially but came off with a little force)

The wiper arms are looking pretty tired with most of its black finish being chipped off, these will be replaced sometime in the future.

A great contrast from before and after, looking fabulously clean.

Parts Purchased

None

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

TASK 31 - Replace Front Number Plate Mount and Renew Front & Rear Number Plates

27-09-2018

One of the small little tasks to do was to refresh the front number plate mount.

There is quite a considerable graze on the right hand side of the mount with the front number plate beings scratched also.

I was thinking of sanding down the mount and refreshing it with flexible external trim paint, however a brand new part from Honda was only £36.00 and they are easy to fit having previously removed the bumper to check its current status and to ensure nothing was seized up.

An order was placed for a new genuine front number plate mount.

Both number plates were looking rather tired too so an order was placed for brand new front and rear number plates.

The rear plate was fitted with ease, using the old number plate as a template for the mount holes.

A 2.5mm pilot hole was drilled first followed by 4.8mm drill size to accept the suitable self tapping screw.

Yellow screw caps were used to hide the screws for a tidy finish.

The front number plate mount required the front bumper to be removed.

Already having performed this previously, it was straight forward.

With the front bumper removed, the number plate mount fixings can be loosened.

The mount was held in by x2 10mm flanged bolts

A couple of retaining clips had to be pryed away but the mount came away cleanly.

The area behind the mount was given a good clean and polish.

The installation was a breeze and was the reverse of removal.

Once installed, the new front number plate was measured up with new holes

(the old holes were through a character either side of the registration number which was not acceptable)

The screw holes were marked up to the unused section of the number plate near the edges.

A 2.5mm pilot hole was drilled first followed by 4.8mm drill size to accept the suitable self tapping screw.

White screw caps were used to hide the screws for a tidy finish.

Once finished, the bumper was re-installed.

The new plates and mount completes the front end refresh.

Parts Purchased

Part: Genuine Honda Number Plate Mount Holder

Part Number: 71180-S2A-G00

Supplier: Coxmotorparts

Part: Front and Rear Number Plates with fixing kit

Part Number: N/A

Supplier: In Car Products (on ebay)

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

TASK 32 - Remove and Replace Auxiliary Belt, Idler and Tensioner Pulley Bearings

21-10-2018

One of the last maintenance tasks that needed doing was to replace the auxiliary belt, there is a stretch indicator on the belt tensioner which indicates the current belt is way past its best.

The car still started up fine with no squeal or belt slipping, but it was the right time to renew this assembly.

As shown from the image below, the current belt is way out of specification and pretty stretched out.

The belt is most likely the original one.

With that in mind, it was also a good opportunity to replace the idler and tensioner pulley bearings.

I was going to buy the full idler and tensioner pulleys with their bearings direct from Honda, however a fantastic video from DIYguys on Youtube showed that the bearings themselves can easily be hammered out and replaced.

The pulleys themselves take the common 6203 size bearing with the 2RS model being the recommended low cost alternative.

With this info, I set about ordering the parts.

The auxiliary belt from Honda was over £65.00, again I am all for genuine parts but the price for a belt is pretty ridiculous. Various threads on s2ki showed that the Contitech and gates make excellent alternatives and at a fraction of the cost. The belt change is really straight forward so if this aftermarket belt doesn't last that long they can be replaced easily in 5 mins.

I decided to purchase a Contitech belt from Eurocarparts, with their usual promotional discount it came to £12.39 posted. Absolute bargain.

There were several manufacturers for the bearings, like SRF and Koyo. I decided to purchase a pair of Koyo 6203-2RS bearings. The seller sent me the 2RS-C3 version which has the additional internal radial clearance.

However this should still be fine, it has been installed and operating well so far after 300 miles of driving.

The process was pretty straight forward and enjoyable too.

Everything came apart as expected with no major issues encountered.

Before removing the idler and tensioner pulleys, they were checked to see how worn they were.

Notice how much side to side play the tensioner bearing had and how worn the idler bearing was.

It kept on spinning with a ticking type sound.

See videos below

My Worn Idler Pulley

My Worn Tensioner Pulley

The original belt had seen better days, various chips in the belt grooves can be seen.

This was noticed all over the belt.

There were also small cracks in the ribbed grooves too.

From DIYguys video, the only socket I didn't have was the large 1-13/16" socket to rest the tensioner pulley on.

I had to purchase this.

Whilst you are in this area, it is also worth checking the condition of the alternator pulley, water pump pulley and air con compressor.

Ensure the water pump pulley spins freely in both directions with no side to side play and ensure no leaks are present. Ensure the alternator pulley also spins freely and check for play and movement. Perform the same checks to the air con compressor.

Give the surrounding areas a good clean and wipe down before reassembling.

Close up of Idler and Tensioner pulley

Close up of ilder pulley and its original bearing

New bearings installed into Idler and tensioner pulleys

With new belt installed

Belt stretch indicator now within specification

A fantastic result and a job that is well worth doing on the s2000.

Things to note

-Unless you have a super fancy torque wrench, it was noticed that my torque wrench doesn't torque up in reverse, so this would need to be done manually.

-As stated on DIYguys video, don't forget the bolt holding the tensioner pulley is a reverse thread

-As mentioned above, perform checks on the water pump, alternator and air con compressor.

-If you have alittle more time, you can refurbish (i.e sand and quickly spray paint the pulleys to smarten them up alittle)

Parts Purchased

Part: Koyo 6203-2RS Bearings (x2)

Part Number: 6203-2RS

Supplier: D.cjohnsonltd (Ebay seller)

Part: 1-13/16" 3/4 Inch Square Drive Socket

Part Number: 1-13/16"

Supplier: Toolvillage (Ebay seller)

Part: ContiTech Drive Auxiliary belt (s2000)

Contitech Part Number: 6PK1468

Supplier: Eurocarparts

For reference (Aux belt part numbers)

Eurocaparts Part Number: 202770585

Genuine Honda Part Number: 38920-PCX-024

Services Used:

None

Resources used

DIYGuys Video (Pulley Replacement)

S2ki Thread - Auxiliary Belt Options

https://www.s2ki.com/forums/uk-irela...nions-1188187/

--------------------------------------------------------------------------------------------------------------------------

This brings the car up to date, I have tried to cover as much I could in such a short space of time and before the winter arrives.

I am happy with the way the car drives and looks and now need to drive it more.

This is a small remaining to-do list and will fulfil them with funds allow.

To-do List

-Renew or Refurbish Front Windshield Wiper Arms

-Upgrade Front Pads to Ferrodo DS2500 Type

Long Term To-Do

-Full Geometry Alignment

-Upgrade Oil Jet Bolts (Was a TSB on my year of s2000)

Maybe's

-Refurbish All Wheels

Thanks for reading

03-11-2018

27-08-2018

From the past couple weeks, it had been noticed that the radiator and A/C radiator fans turn on immediately after pre ignition, engine start and on a cold engine. The engine temperature would be ok and no overheating was present.

The radiator fan should only switch on when the coolant reaches a certain temperature, I think around 93-95 degrees. I set about to find out what was wrong.

Thanks to a few old s2ki forum threads, I performed a few tests to find a root cause to the problem.

The threads pin pointed the radiator fan switch to be the most likely problem.

I performed a few tests to confirm this:

-Swapped over the radiator fan switch relay (there is an identical relay within the fuse box)

Result: No difference

-Disconnect the radiator fan switch itself

(fan switch is located on the left hand bottom section of the radiator)

Result: On pre-ignition, engine start and cold engine, the radiator fans do not switch on.

With the above findings it concluded that the existing radiator fan switch is stuck in the closed position.

I am all for sourcing and using genuine Honda parts but for something quite relatively easy to change, several members have recommended a good after market brand.

The Honda OEM part, cheapest I found was £67.00 (Usual RRP £94.00)

After market type: £13.00

The brand of the aftermarket type was Canbiare which is a well known European brand.

I decided to go for this one.

The switch was relatively easy to access, and from several threads it required no coolant bleeding when swapping it out within the radiator which was a plus point.

The lower under tray was a tad tricky to remove with most of its clips crumbling upon removal.

It would seem that it had never been removed.

With the under tray removed, a good general clean was also performed.

The radiator fan switch has a size 24mm hex and a deep socket was required to remove it.

I realised this quite late and didn't have one in the tool box.

A trip to Halfords solved this.

Just a little spillage of coolant during the quick swap over and that was it.

The radiator fan switch is located at the bottom of the radiator when the red arrow is pointing.

Upon engine start and warm-up the fans kicked in as normal and switched off as expected.

A long 40 min drive confirmed full function had been restored.

The old radiator fan switch removed

Parts Purchased:

Part: Radiator Fan Switch

Honda Part Number: 37760-P00003

Canbiare Part Number: VE709047

Supplier: Car Parts In Motion (Ebay Seller)

Tool: 24mm Deep 1/2 inch Socket

Supplier: Halfords

https://www.halfords.com/workshop-to...24mm-1-2-drive

Services Used:

None

Resources used

S2ki Thread: Fans Always on

https://www.s2ki.com/forums/uk-irela...lways-1131621/

Thread I Started

https://www.s2ki.com/forums/uk-irela...arket-1187554/

--------------------------------------------------------------------------------------------------------------------------

TASK 26 - Remove Rear Bumper & Lights (Clean and Under Seal)

28-08-2018

The next task on the agenda was to remove the rear bumper, this would give the opportunity to have a peek behind and see the condition of the rear beam and chassis area.

The bumper removal was pretty straight forward and with the process fairly common with most Honda's. Two screws on either side into the rear quarter, clips on top of the rear bumper, three clips on the bottom section of the rear bumper and two clips either side of the arch.

Once the bumper was off the condition of the rear beam and chassis sections weren't too bad. Few light rust spots with the rear beam rusty in a few places. From research, it seems the rear beam is common to rust due to its location and having no protection from any stone chips.

All sections were cleaned and the wire brush came out, light rust spots were brushed with the rear beam also being tidied up the best it could.

Hammerite rust remover was applied on required areas and then followed a coat of dinitrol under seal spray.

A general clean and wipe down was given to all other areas.

Rear number plate bulbs were replaced and terminals greased up to prevent corrosion

The rear lights were removed inspected and cleaned.

All sections behind the lights were in great condition with no leaks or rust.

The connectors were checked and no signs of corrosion was present.

No moisture or leaks were present behind the boot trim.

The light cluster gaskets were checked and cleaned.

The rear bumper was re-installed and new clips were used in all locations.

Parts Purchased:

Part: Dinitrol Under seal Spray 500ml x3

Part Number: 4941

Supplier: MTS Trading (on ebay)

Part: Hammerite rust remover (gel)

Part Number: 5092868

Supplier: Halfords

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

TASK 26 - Remove Front Bumper (Clean and Rust Treat as Required)

02-09-2018

It made sense that the next task was to perform a front bumper removal.

This would also be an opportunity to check for any rust or damage within this area.

Again, the front bumper removal is similar to all Honda's, two screws either side of the front arch, several bolts on the top section of the bumper, two hidden 10mm bolts either side facing the headlamps and several bolts on the underside of the bumper.

Both front arch liners were also removed to aid in access.

Once the bumper was carefully removed the condition of the front sections of the car were also in pretty good condition, with a few rust spots on the front cross beam and various brackets as one would expect.

The rust spots were rubbed down and Hammerite rust remover was applied, followed by a quick coat of touch up paint.

An overall wipe down of all areas were performed and it was looking really fresh.

The air pump was checked and seemed in good clean condition, the previous owner had not tempered with it.

It is common for owners to delete this component if it fails, as it is in good working condition it will be left alone.

The air pump is designed to blow air into the exhaust system upon a cold engine start to quickly heat up the catalytic converter and thus reduce emissions from cold starting.

If you're air pump has failed, you would get a MIL (malfunction indicator lamp) appear on your dash cluster.

If your fault code has detected that the air pump has failed, you can delete it with a special kit from a company called "Delta Lima"

There will be no operating issues, only slightly higher emissions when the car is started from cold.

This will not affect your MOT as the car will be fully warmed and up to operating temperatures when emissions are tested.

The kit has been proven by many s2000 members on this forum.

The bumper itself was checked for damage and also cleaned.

The front number plate and holder were examined, all bolts mounting the holder were clean and not seized.

Due to some cosmetic damage to the number plate holder and number plate itself, I will be replacing both these items later on so it was good to see it will be hassle free.

Parts Purchased:

Part: Hammerite rust remover (gel)

Part Number: 5092868

Supplier: Halfords

Services Used:

None

Resources used

None

If required - Air Pump Delete Kit from Deltalima

https://www.s2ki.com/forums/european...e-kit-1139689/

EGR-Airpump delete (English) – Deltalima-S2000.nl

------------------------------------------------------------------------------------------------------------------------

Task 27 - Rear Mid Level Spoiler

07-09-2018

The s2000 does look fantastic as standard, but I have always loved the look of the mid level spoiler that comes on a few models. This spoiler is an upgrade accessory and apparently still available from Honda, the only issue with the genuine part is that it is quite expensive and requires holes to be drilled within the boot lid to attach it which I refuse to do.

After a search on the forum, there is an aftermarket cheaper and easy to fit solution.

A highly recommended seller which goes by the name of "BMWchop" (a seller on eBay)

From reviews and feedback from many threads on s2k UK, the shape of the spoiler, quality and paint match is amazing.

Many members have reported nothing but good things and from all the images posted up it looks and fits fantastic.

I was convinced by this so had to try it for myself, an order was placed for NH630 pre-painted version and with a handy 10% eBay voucher at the time it worked out even cheaper.

The seller was very efficient with it arriving in just two days and no import duty charge! Great result.

He spoke good English and kept me up to date.

Arrival of the spoiler

Once arrived, a test fit was performed. The colour match was fantastic and the fitment was excellent.

Very impressed indeed, given its price.

On fitment I tried the supplied double sided adhesive tape, but I didn't feel confident that it would stick well despite various reports from other members that it was fine.

I decided to purchase some 3M automotive Vey High Bond adhesive.

I purchased the longer thinner strip (1.5mm thick tape 3M Automotive very High bond Adhesive) for the top and bottom edges of the spoiler.

https://www.ebay.co.uk/itm/3M-VHB-Do...53.m2749.l2649

For the spoiler end sections I used slightly thicker (2.3mm 3M Automotive very High bond Adhesive)

(These came in a small square 100mm x 50mm size which I cut up into two strips of 50mm x 25mm and positioned them either side of the spoiler.

https://www.ebay.co.uk/itm/3M-VHB-10...53.m2749.l2649

The reason why I went for a slightly thicker tape on the end sections is the recess is slightly deeper where the spoiler curves into the ends of the boot edge.

The underside of the spoiler was sanded down to provide an abraded surface for the double sided adhesive to adhere well too.

Once all the tapes was positioned on the spoiler, I got to work to fit it.

The boot lid surface was cleaned with fairy liquid to ensure a clean grease free surface.

I didn't have any masking tape so I just used what I had in my tool box.

Electrical tape was used to provide me with a guide for fitment as this would be a onetime action.

Once suitably aligned within the position marked, the self adhesive backing was removed and the spoiler was pressed into position.

Attachment 152447

The bond of the tape is fantastic, It definitely gives that confidence of a good adhesion to the boot lid.

The spoiler looks fantastic and definitely gives the s2000 a much sportier look.

Extremely happy with the look, quality and results, highly recommended.

Attachment 152448

Parts Purchased

Part: s2000 Mid Level Spoiler

Part Number: N/A

Supplier: BMWchop (on ebay)

Part: 3M Automotive Very High Bond Double Sided Tape (Reel) (1.5mm Thick)

Part Number: RP62

Supplier: fasttapes (on ebay)

Part: 3M Automotive Very High Bond Double Sided Tape (2.3mm Thick)

Part Number: 3M VHB 4991

Supplier: happy-london-tapes (on ebay)

Services Used:

None

Resources used

S2k Thread - Spoiler Recommendation

https://www.s2ki.com/forums/uk-irela...dvice-1103781/

S2k Thread - Adhesive tape for Spoiler

https://www.s2ki.com/forums/uk-irela...kness-1187765/

------------------------------------------------------------------------------------------------------------------------

Task 28 - Genuine Front Pre-Face Bumper Lip

07-09-2018

I've always loved the look of the pre facelift s2000 with a front lip as it added a subtle aggression to the s2000 without going over the top.

I had an urge to source one but wasn't sure if they were still available.

After several enquiries it became apparent that Honda still had stock of them and they were available in my pre painted Silverstone metallic colour

Fantastic result.

Unfortunately, the price of this part had increased dramatically over the years and I had to decide whether or not it was worth to pay such a price for one.

I tried to search for alternatives just like with the mid level spoiler.

There were replica's available but from reviews/feedback, the fitment is not great and unless you have a body shop to hand to help fit, paint and attach it, alot of people say to avoid them as the costs and hassle involved isn't worth it.

The genuine part comes pre-painted and attaches as any genuine part does. Utilising existing mounting points with the supplied hardware it takes on average 20mins to fit and the fitment should be perfect.

I contemplated long and hard about it, and thought what the hell. This would most likely be my last upgrade to the car.

Let's go for it.

I placed an order and within 3 days it arrived. The paint finish and quality is as you would expect from a genuine part, flawless. I was glad a genuine part was purchased.

The box was huge!

Fitting the lip was straight forward, with the supplied instructions it just needed the removal of the three centre bolts from the underside of the bumper and a couple of pilot holes drilled on either side of the bumper edges for self tapping screws for the front lip end attachment.

A further 2 bolts per side on the underside were required with the supplied fastening bolts.

A hint of copper grease was used on all bolts and screws for easy removal in the future.

The lip wrapped around the bumper perfectly like a glove and with all the bolts securing it, installation was complete within 30mins and that was me taking my time including adding a layer of wax behind the bumper section that will be covered by the lip.

Fantastic transformation, the front lip does really look good on the pre-face lift s2000.

Fully installed

A great buy and highly recommended to any pre-face lift owner.

Parts Purchased

Part: Genuine Front Under Lip (pre painted in Silverstone metallic)

Part Number: 08F01-S2A-681F

Supplier: Coxmotorparts

Services Used:

None

Resources used

Supplied Instruction Manual for Front Lip Fitting

Also can be found online here

https://www.handa-accessories.com/S2000/s2kfuspoil.pdf

------------------------------------------------------------------------------------------------------------------------

TASK 29 - Investigate Water Leak into Driver Footwell - (PROBLEM 2)

10-09-2018

In the early months of my s2000 ownership, it was noticed that a small water leak was apparent.

This was resolved my repairing the rubber seal on the A-pillar which now re-directs the water as it should out into the door channel recesses.

After a few more heavy rainfalls it was noticed that a slight trickle of water was still entering the cabin and making the carpet underneath the drivers pedals slightly wet. The water seemed to also be absorbed up within the insulation in this area underneath the main floor carpet.

The previous owner never really suffered from this as the car was stored under a car port.

This was on the agenda and was vital I resolve this before winter approaches.

Even getting additional help from a garage to completely strip the interior to find the root cause if required .

I set aside a full day of diagnosis and went about eliminating various sections just to make sure I covered all areas.

Not having any access to a hose pipe or running water I relied on my battery powered portable jet washer to simulate rainfall. Known as the Mobi V17, other similar models are known and manufactured by Sealey or Aqua2go if interested.

Fantastic bit of kit, stores around 18 litres of water and provides excellent suitable pressure.

I checked all the seals around the windows and roof. Moving towards the front and around the A-pillars.

This included all drain points in the engine bay and the drain point under the windscreen wiper cowling

I double checked and removed all the A-pillar plastic mouldings.

No sign of any water entering.

The rear roof drains were checked and confirmed water was draining fine in this section.

The next stage was to remove the wind screen wiper cowling section.

(this will also be documented separately on the next task for inspection and clean)

With the cowling removed, the wind screen seal was inspected with no defects apparent.

The windscreen is still the original Honda part which gave a good sigh of relief it had not be tampered with or previously replaced.

Back into the driver's footwell, I removed the x2 bolts holding the foot rest and the lower right side panel which sits over the bonnet release catch (the driver's door side sill) needs to be unclipped and removed first.

In this state, water can be sprayed and hopefully monitor its point of entrance.

Water drain points are located in the upper corner of the drivers engine bay and another one under the bonnet hinge area.

I used my battery powered pressure washer to direct water at these drain points whilst monitoring.

To my amazement, the water was found trickling into the cabin very slowly. The area where it entered was to the right hand side where the bonnet release cable exits the cabin.

There seemed to be a missing seal or grommet surrounding this cable, a brief look later through the receipts proved that the bonnet release cable was replaced in 2009 and the garage who replaced it did not re-fit the grommet seal.

Item 10 required

The part is still readily available from Honda and only around £4.54.

An order was replaced with a very quick lead time of a few days.

Once the part arrived the fitting was straight forward, the carpets were given a good scrubbing with autoglym shampoo. All underlay sections of the carpet was ensured fully dry using my hobby heat gun.

Some copper grease (all I had at the time)was used on the cable and grommet to allow the grommet to feed itself easily through the cable. It was quite tricky but with alittle patients the grommet secured itself nicely within the aperture sealing it perfectly.

Grommet installed

The end clip to hold the bonnet release plastic panel in place was also purchased as this was original missing when the car was purchased.

All components fully reassembled

Hopefully this saga can now be put to rest.

A fantastic result, I couldn't have asked for a better outcome

Parts Purchased

Part: Grommet Seal for Bonnet Release Cable

Part Number: 74134-SM-4000

Supplier: Coxmotorparts

Part: 7mm Clip to Secure Side Panel

Part Number: 90667-S0D-003ZH

Supplier: Coxmotorparts

Services Used:

None

Resources used

My Mobi V17 Portable Pressure Washer.

Now known as Aqua2go.

https://www.aqua2go.eu/en/overview.html

--------------------------------------------------------------------------------------------------------------------------

TASK 30 - Remove Windscreen Wiper Cowling (Inspect and Clean)

09-09-2018

During the above investigation and after it was solved, it made sense to also inspect and clean this area of the car. With the cowling assumed not having been removed throughout the car's lifetime it definitely showed.

Cobwebs, debris and leaves were everywhere and as expected.

A quick hose down using the portable jet washer removed most of the dirt

(Special care was taken not to soak or get the cabin filter wet)

With the cowling removed, the filter panel and the fan housing down into the heater matrix was fully inspected and checked.

Additional wiping down of various sections continued the clean.

All fittings and cables were inspected with no evidence of any tampering or modifications.

Small surface rust was rubbed down and treated on the centre clip section.

A slight hint of copper grease was used on the wiper motor attachments so the wiper arms do not seize up in the future. (they were quite tricky to remove initially but came off with a little force)

The wiper arms are looking pretty tired with most of its black finish being chipped off, these will be replaced sometime in the future.

A great contrast from before and after, looking fabulously clean.

Parts Purchased

None

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

TASK 31 - Replace Front Number Plate Mount and Renew Front & Rear Number Plates

27-09-2018

One of the small little tasks to do was to refresh the front number plate mount.

There is quite a considerable graze on the right hand side of the mount with the front number plate beings scratched also.

I was thinking of sanding down the mount and refreshing it with flexible external trim paint, however a brand new part from Honda was only £36.00 and they are easy to fit having previously removed the bumper to check its current status and to ensure nothing was seized up.

An order was placed for a new genuine front number plate mount.

Both number plates were looking rather tired too so an order was placed for brand new front and rear number plates.

The rear plate was fitted with ease, using the old number plate as a template for the mount holes.

A 2.5mm pilot hole was drilled first followed by 4.8mm drill size to accept the suitable self tapping screw.

Yellow screw caps were used to hide the screws for a tidy finish.

The front number plate mount required the front bumper to be removed.

Already having performed this previously, it was straight forward.

With the front bumper removed, the number plate mount fixings can be loosened.

The mount was held in by x2 10mm flanged bolts

A couple of retaining clips had to be pryed away but the mount came away cleanly.

The area behind the mount was given a good clean and polish.

The installation was a breeze and was the reverse of removal.

Once installed, the new front number plate was measured up with new holes

(the old holes were through a character either side of the registration number which was not acceptable)

The screw holes were marked up to the unused section of the number plate near the edges.

A 2.5mm pilot hole was drilled first followed by 4.8mm drill size to accept the suitable self tapping screw.

White screw caps were used to hide the screws for a tidy finish.

Once finished, the bumper was re-installed.

The new plates and mount completes the front end refresh.

Parts Purchased

Part: Genuine Honda Number Plate Mount Holder

Part Number: 71180-S2A-G00

Supplier: Coxmotorparts

Part: Front and Rear Number Plates with fixing kit

Part Number: N/A

Supplier: In Car Products (on ebay)

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

TASK 32 - Remove and Replace Auxiliary Belt, Idler and Tensioner Pulley Bearings

21-10-2018

One of the last maintenance tasks that needed doing was to replace the auxiliary belt, there is a stretch indicator on the belt tensioner which indicates the current belt is way past its best.

The car still started up fine with no squeal or belt slipping, but it was the right time to renew this assembly.

As shown from the image below, the current belt is way out of specification and pretty stretched out.

The belt is most likely the original one.

With that in mind, it was also a good opportunity to replace the idler and tensioner pulley bearings.

I was going to buy the full idler and tensioner pulleys with their bearings direct from Honda, however a fantastic video from DIYguys on Youtube showed that the bearings themselves can easily be hammered out and replaced.

The pulleys themselves take the common 6203 size bearing with the 2RS model being the recommended low cost alternative.

With this info, I set about ordering the parts.

The auxiliary belt from Honda was over £65.00, again I am all for genuine parts but the price for a belt is pretty ridiculous. Various threads on s2ki showed that the Contitech and gates make excellent alternatives and at a fraction of the cost. The belt change is really straight forward so if this aftermarket belt doesn't last that long they can be replaced easily in 5 mins.

I decided to purchase a Contitech belt from Eurocarparts, with their usual promotional discount it came to £12.39 posted. Absolute bargain.

There were several manufacturers for the bearings, like SRF and Koyo. I decided to purchase a pair of Koyo 6203-2RS bearings. The seller sent me the 2RS-C3 version which has the additional internal radial clearance.

However this should still be fine, it has been installed and operating well so far after 300 miles of driving.

The process was pretty straight forward and enjoyable too.

Everything came apart as expected with no major issues encountered.

Before removing the idler and tensioner pulleys, they were checked to see how worn they were.

Notice how much side to side play the tensioner bearing had and how worn the idler bearing was.

It kept on spinning with a ticking type sound.

See videos below

My Worn Idler Pulley

My Worn Tensioner Pulley

The original belt had seen better days, various chips in the belt grooves can be seen.

This was noticed all over the belt.

There were also small cracks in the ribbed grooves too.

From DIYguys video, the only socket I didn't have was the large 1-13/16" socket to rest the tensioner pulley on.

I had to purchase this.

Whilst you are in this area, it is also worth checking the condition of the alternator pulley, water pump pulley and air con compressor.

Ensure the water pump pulley spins freely in both directions with no side to side play and ensure no leaks are present. Ensure the alternator pulley also spins freely and check for play and movement. Perform the same checks to the air con compressor.

Give the surrounding areas a good clean and wipe down before reassembling.

Close up of Idler and Tensioner pulley

Close up of ilder pulley and its original bearing

New bearings installed into Idler and tensioner pulleys

With new belt installed

Belt stretch indicator now within specification

A fantastic result and a job that is well worth doing on the s2000.

Things to note

-Unless you have a super fancy torque wrench, it was noticed that my torque wrench doesn't torque up in reverse, so this would need to be done manually.

-As stated on DIYguys video, don't forget the bolt holding the tensioner pulley is a reverse thread

-As mentioned above, perform checks on the water pump, alternator and air con compressor.

-If you have alittle more time, you can refurbish (i.e sand and quickly spray paint the pulleys to smarten them up alittle)

Parts Purchased

Part: Koyo 6203-2RS Bearings (x2)

Part Number: 6203-2RS

Supplier: D.cjohnsonltd (Ebay seller)

Part: 1-13/16" 3/4 Inch Square Drive Socket

Part Number: 1-13/16"

Supplier: Toolvillage (Ebay seller)

Part: ContiTech Drive Auxiliary belt (s2000)

Contitech Part Number: 6PK1468

Supplier: Eurocarparts

For reference (Aux belt part numbers)

Eurocaparts Part Number: 202770585

Genuine Honda Part Number: 38920-PCX-024

Services Used:

None

Resources used

DIYGuys Video (Pulley Replacement)

S2ki Thread - Auxiliary Belt Options

https://www.s2ki.com/forums/uk-irela...nions-1188187/

--------------------------------------------------------------------------------------------------------------------------

This brings the car up to date, I have tried to cover as much I could in such a short space of time and before the winter arrives.

I am happy with the way the car drives and looks and now need to drive it more.

This is a small remaining to-do list and will fulfil them with funds allow.

To-do List

-Renew or Refurbish Front Windshield Wiper Arms

-Upgrade Front Pads to Ferrodo DS2500 Type

Long Term To-Do

-Full Geometry Alignment

-Upgrade Oil Jet Bolts (Was a TSB on my year of s2000)

Maybe's

-Refurbish All Wheels

Thanks for reading

03-11-2018

Last edited by s2000_f20; 11-03-2018 at 12:46 PM.

The following users liked this post:

Arussto (12-23-2021)

#22

Nice work! Can I give you a couple of heads up? First with the rear bumper off you seem to have the towing eye extension screwed into the bar, it should be taken out and stored in the tool tray, reason being if the bumper gets a nudge it will pop the cover out.

Secondly if fitting parts with tape don't rough up the surface, adhesive tape needs a smooth surface to adhere best, shouldn't be a problem but it might fall off in 30 years time! Only rough up a surface when using liquid glues like epoxy etc.

Secondly if fitting parts with tape don't rough up the surface, adhesive tape needs a smooth surface to adhere best, shouldn't be a problem but it might fall off in 30 years time! Only rough up a surface when using liquid glues like epoxy etc.

#23

Left hand thread did not know that for the pulley may of saved a major issue

#24

Registered User

Thread Starter

Thanks Richmc,

Cheers for the heads up, I didnt know that about the towing eye extension. My tool set for the s2000 is all complete and nothing is missing.

You sure this is not standard to have it on there for the early s2000's?

Duly noted with regards to the rough and smooth surfaces. It should be ok, it is firmly attached and it is definitely not going anywhere.

Cheers Noodels - Your welcome. Have to thank DIYguys though. Couldn't have done it without his video.

Cheers for the heads up, I didnt know that about the towing eye extension. My tool set for the s2000 is all complete and nothing is missing.

You sure this is not standard to have it on there for the early s2000's?

Duly noted with regards to the rough and smooth surfaces. It should be ok, it is firmly attached and it is definitely not going anywhere.

Cheers Noodels - Your welcome. Have to thank DIYguys though. Couldn't have done it without his video.

#25

Registered User

Thread Starter

Hi Guys,

Here’s the next update on the s2000

--------------------------------------------------------------------------------------------------------------------------

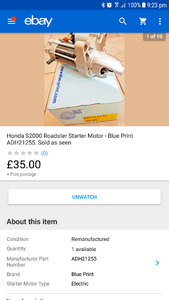

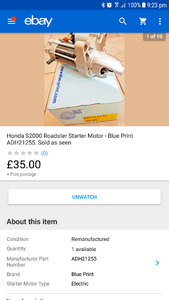

Task 33 - Starter Motor Grind in Cold Conditions

19-11-2018

As soon as the temperatures started to drop I noticed something very odd with the s2000. I occasionally will use the s2000 for work and upon engine start I noticed a slight grind just after the engine fired up.

At first I didn't think anything of it, and thought it was me having my finger on the push start button longer than I should have. As the mornings got colder, I noticed it occurring alot more.

I quickly did a search on the forum, and unfortunately it is a common known issue with the starter motors of all s2000's. It affected all years. (apparently it also affects all k20 engines too)

I was quite disappointed at this, with the s2000 being a flagship car for Honda in its hay day, things like this shouldn't occur. The starter motor part is not cheap with a genuine Honda part coming up at £400. From reading up on several threads, most people tend to just live with it. It does not occur at all in milder or summer weather conditions and as the majority of people tend to only use their s2000's in the summer months it is quite often overlooked.

The issue I have is that the constant grind will eventually cause long term damage to the flywheel, and the grinding sound is truly awful.

The basic reason for the grind is a sticking bendix gear mechanism, the sticking causes a slight delay in retracting the pinion gear after engine start which causes the slight grind.

It is not known if Honda ever knew about this issue, and it is believed the starter motor from Honda was never up-issued or superseded to address the problem at all. So inevitably, if you did change the starter motor it would be only a matter of time until the problem returned again.

With this knowledge, I was intending to just live it with it and not use the car as much during the winter months. However a brand new blueprint s2000 starter motor popped up on eBay, a quick message to the seller I decided to take a punt and did a deal.

I manage to bag it for £35 delivered

Several DIY guides showed that the process to remove and fit a starter motor was quite tricky, doable but tricky. With winter in full motion I decided not to tackle it and have my trusty garage to take care of it.

A quick message to Performance Autoworks, a slot was booked in and the job was done within a couple of hours.

The starter motor worked well upon initial fire, several tests over the next coming days proved that the initial grind had disappeared. A great result all at a great price.

Thanks again to Rich at Performance Autoworks and to the fellow members of s2ki UK forum for help and advice.

Parts Purchased:

Part: s2000 Starter Motor (Blueprint Version)

Blueprint Part Number: ADH21255

Private Ebay Sale: EBay seller "proud2help"

For reference

Genuine Honda Part Number for Starter Motor: 31200-PCX-A02

Services Used:

Performance Autoworks

Performance Autoworks (Fairford/Gloucestershire GL7 4BX)

Contact: Richard Voaden

Tel: 01285 711 733

Email: info@performance-autoworks.co.uk

https://www.facebook.com/pages/Performa ... 1547611908

Resources used

S2ki Thread: "Starter motor grind on cold mornings"

https://www.s2ki.com/forums/uk-irela...nings-1189121/

--------------------------------------------------------------------------------------------------------------------------

Task 34 - Quick Photo Shoot, Somewhere in Fairford.

19-11-2018

Just after the starter motor was replaced, we decided to have a quick blast around the surrounding roads.

A lovely rural car park was found so there was only one thing to do

A quick photo shoot of the car as she stands today.

I didn't have my DLSR camera, so the shots were taken using my Samsung galaxy S6 phone.

Parts Purchased:

None

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

Task 35 - Investigate Water Leak into Boot - (PROBLEM 3)

(Water Ingress Through Soft Top Hood Drainage Channel)

24-11-2018

Whilst I was washing the s2000 on the weekend, it was noticed that the boot floor on the right hand corner was slightly wet. It was at this instant, I knew I was another victim of the s2000 dreaded water in the boot syndrome.

First task was to strip the boot entirely of its interior trim, all interior trim came out with ease.

There was one tricky bolt securing the OEM CD changer, this attaches the cradle from underneath the chassis. Once removed the main floor trim came out with ease.

Once all the trim was removed, the water also found its way into the main centre section of the boot floor where it had just started to rust.

A quick mop up of the standing water, wire brush with my cordless drill and a couple coats of hammertite paint quickly removed the rust and further protected it.

The condition of the boot was in pretty good shape and there seemed to be no evidence of any crash damage.

With that sorted, the next task was to try and locate the water leak. A quick spray over the hood showed that the water was entering the boot on the back section of the soft top hood. It appeared to be entering with a slow drip just in the corner from the drain gutter channel.

The leak was now located but it would be the furthest I could go without dismantling the hood.

It would seem there is a U shaped gutter channel surrounding the back edge of the hood, rain water collects in these channels and directs it to the side of the car.

Photos courtesy of user: Mike’s

With that in mind, my options were either to replace the hood or find a hardtop.

I made some enquiries for the best places for hood replacements, the top ones being Jack Smiths or Monsoon Hoods. I really wanted a hardtop, so the search continued to see if I could get one.

Parts Purchased:

None

Services Used:

None

Resources used

Monsoon Car Hoods

https://www.monsooncarhoods.co.uk/

Jack smith Hoods

https://www.facebook.com/JackRSmithMotorTrimmers/

(Jack smiths does not have a website nor does he communicate via email)

Note: telephone is his only form of communication

--------------------------------------------------------------------------------------------------------------------------

Task 36 - Hardtop Purchase

02-12-2018

Whilst browsing the forums and eBay, an s2000 hardtop in Silverstone silver popped up on eBay.

From the images it looked in fabulous condition.

Further enquiries led to additional images and some very minor scratches to the right had side of the hardtop.

There was some minor scratches on the inside upper interior on the passenger side which I didn't mind.

We discussed its pricing and then we struck an agreement.

Overall, for the price it was a fantastic deal, and it would have been too good of a price to pass even with the slight defects.

This would now solve my immediate water leaking issues, I intend to keep the hardtop on until I find the additional funds to replace the hood at a later date.

I've always loved the look of the hardtop, it just completes the fantastic lines of the s2000.

I had a quick look at the original Honda instructions for installing the hardtop, just to be familiar with the process.

The day came to pick up the hardtop. They were based near Bournemouth so it was approx 2 hour drive from home.

It was constantly raining on and off throughout the day, nevertheless, I got there with no drama's or hold ups on the roads and it was great drive. There are some fab roads down there.

The seller was very pleasant and was gutted to let the hardtop go, he had his s2000 for 12 years until he was a victim of the s2000 twitchy rear end. His s2000 was written off.

The hardtop was more fiddly to install than I expected, but the spike brackets lined up great and the front strikers were clamped securely, the revised hardtop strikers will most likely be needed but I will purchase these at a later date. The install was definitely a two person job.

It needs a good clean having been in their garage for many years, but overall I was very pleased with the results.

With the s2000 being a 1999 model, I did not have the circuitry for the rear heater demister, my next task would be to possibly find out if I can get this feature all up and running.

After a few rainy days, it had been confirmed that no further water leakage was entering the boot via the roof area.

However, before re-installing the boot trim the common rear bumper vent will be siliconed up as a precaution.

This to follow at a later task.

Further research shows that a specific loom for the rear heater circuitry has now been discontinued from Honda.

This is specific for the 1999-2001 model of the s2000.

In light of this information, I will be dropping the plans of commissioning the rear demister setup.

Parts Purchased:

Part: s2000 Genuine Hardtop Roof

Honda Part Number: Unknown

Private Sale: EBay seller 2nd Hand

Services Used:

None

Resources used

PDF of hardtop installation Instructions

https://www.handa-accessories.com/s2000/s2k2top.pdf

S2ki thread - Rear Heater Demister Circuitry

https://www.s2ki.com/forums/uk-irela...r-my00-916782/

--------------------------------------------------------------------------------------------------------------------------

Task 37 - Investigate Water Leak into Boot - (PROBLEM 4)

(Water Ingress Through Antenna)

07-12-2018

After a few heavy rainfalls I kept monitoring the boot for any further water ingress, to my disappointment another pool of water was present on the right hand side of the boot.

Further checks showed clearly that it was now entering through the rear antenna.

Placing my hand up around the base of the antenna inside the boot, it showed water had been dripping through.

This seemed to be another common water entrance point for the s2000.

To remove the fastening nut that secures the antenna mount and seals, a special tool was required.

The special tool that is required seems to be similar to a 90 degree bent pliers used for removing circlips.

However, within my tool box I located a tool to remove rear back cases of watches.

This was ideal for the job and fitted the fastening nut perfectly.

The fastening nut and all seals were removed and inspected.

All seals were in good condition and no rips or tears were present.

A good clean were given to all components, including the surrounding area of the body work where the seals are positioned.

Shin entsui silicone grease was used to coat the seals to restore its suppleness and flexibility.

Re-assembly was straight forward.

After several rainfalls, no further water ingress was present.

It may have seemed that the cause of the water leakage was a loose fastening nut.

New seals and components were still readily available from Honda and were reasonably priced.

However, the current components were in such good condition, I felt there was no need for replacements.

Parts Purchased:

None

Services Used:

None

Resources used

None

--------------------------------------------------------------------------------------------------------------------------

Task 38 - Stereo Removal & Check

18-12-2018

One of the quick easy tasks on the list was to remove the head unit to check for any issues.

The stereo system worked fine, but as this was a very easy task it would be an ideal opportunity to check to see if any dodgy modifications were performed. Especially after seeing the poor execution of the speaker upgrade a while back.

Dealing with anything electronic, it's always ideal to disconnect the main car's battery.

Being an original stereo head unit in known good operating condition, it is not 100% necessary but that is up to you.

The front stereo cover was removed by gently applying outward pressure to the lower section of the cover. The cover pops out revealing the head unit installation screws, 2 self tapers either side of the head unit.

Simply unscrew these and the head unit can be removed. It was that easy.

Thankfully on inspection, it would seem that the head unit has never been touched.

All cabling and wiring are all original, no cutting or splicing was present on any of the ISO block wires.

The head unit's main ISO connector and CD changer connector was unplugged and all its terminals wire brushed and cleaned.

Re-installation was straight forward and a breeze.

Don't forget to re-connect the battery if you disconnected it.

I have no plans in upgrading the stereo, the original system with its original CD changer works fantastic.

Parts Purchased:

None

Services Used:

None

Resources used

Note: If you plan to remove or disconnect the head unit,

Ensure you have the head unit security code to hand, as this will be required upon power up.

(As far as I am aware, all OEM s2000 head units will require a security code if the battery has been disconnected)

--------------------------------------------------------------------------------------------------------------------------

Task 39 - Hardtop Clean

18-12-2018

One of the tasks was to deep clean the hardtop, with the previous owner having stored this hardtop in their garage it needed a good clean.

The first task was to hose down and clean the hardtop as normal, detailing brushes were used to remove dirt and grime from the side crevices and all rubber seals and gaskets were wiped down. The latches were thoroughly cleaned with brushes and the headliner was also wiped down.

Being on my own, the hardtop cannot just be removed and placed on the floor to clean, so I had to do what I could with the hardtop slightly unbolted.

Once the hardtop was clean, the rear side interior inner panels were removed, this area was covered in spider webs and dead spiders, it wasn't a pleasant sight. I didn't take a pic of this as I just plodded on in hoovering it all up.

Area now completely clean

Once I was happy with the cleanliness of the hardtop, it was now a case to quickly DA polish the paint work.

I don't have mains power out in the car park, so I had to make use of a DA attachment to a cordless drill.

It is not to bad and useful in removing light marks and blemishes. Meqguries compound polish was used.

After the polishing session, all seals were coated in Shin Entsui silicone grease.

This included the seal which mates to the rear boot lid deck and the seal which mates to the front top section of the windshield. A hardtop will always make noises due to the fact it is not physically part of the car, however siliconing all these seals is highly recommended to help prevent annoying squeaks and rubbing noises.

A rattling noise was also present which was due to the front strikers being the original version and worn out.

Hardtop front striker upgrade will be purchased and installed later to further reduce this hardtop rattling sound.

Parts Purchased:

None

Services Used:

None

Resources used

Meguires DA Drill Attachment Polisher

--------------------------------------------------------------------------------------------------------------------------

Task 40 - Investigate Water Leak into Boot - (PROBLEM 5)

(Water Ingress Through Rear Bumper Vent)

28-12-2018

From the previous water ingress issue (Problem 4), the boot was still in a stripped down state as this allowed me to monitor and see if there were any further water ingress issues.

After several checks ,it was confirmed that a very small drip was coming from the rear bumper's one way vent after several heavy rain falls.

Again, this is another common water entry point on all s2000's.

The gasket seal around this vent perishes over time, and can allow water ingress filling up the base pan of the boot.

Due to the tool set being on top of this area, owners tend not to realise that water has been settling underneath for quite some time.

The s2000 is now 20 years old, so it was understandable that this gasket has lost its ability to seal.

To resolve the issue it required the rear bumper to be removed.

On a mild winter's day during the Christmas holidays, I set about to get this sorted.

The rear bumper was removed easily as it was removed on a previous task.

Once the bumper was removed, the vent can be seen. It is unclipped from inside the boot area.

(note: Boot trim to the rear of the car needs to be removed if not already done so)

Once unclipped, the vent can be removed with ease.

The gasket seal was still intact but it was starting to loose its adhesion.

The gasket was peeled away and removed completely.

With the gasket removed, the vent was thoroughly cleaned and checked for any other defects.

Once I was happy no other defects was present, I continued to prep the mating area. This was cleaned and lightly abraded to allow the silicone to adhere to it.

The side clips have to be discarded to allow a flush fit between the vent and chassis.

The silicone chosen for the job was a marine grade type, there are many types of silicone variants available so I wanted one that will last and be a one time job.

I choose Geocel's marine grade type silicone in black.

It was applied to the chassis section and on the vent itself, once applied, the vent was mated up to the chassis.

Force was applied for several minutes to keep it in place and then it held on by itself.

Once cured (24 hours), it gave a superb excellent long lasting seal.

It was then tested and confirmed water tight.

An easy DIY that has now hopefully ended my water ingress issues.

Parts Purchased:

Part: Geocel Marine Silicone (Black Colour)

Part: N/A

Ebay Link

https://www.ebay.co.uk/itm/Geocel-Ma...53.m2749.l2649

Services Used:

None

Resources used